Excerpt:

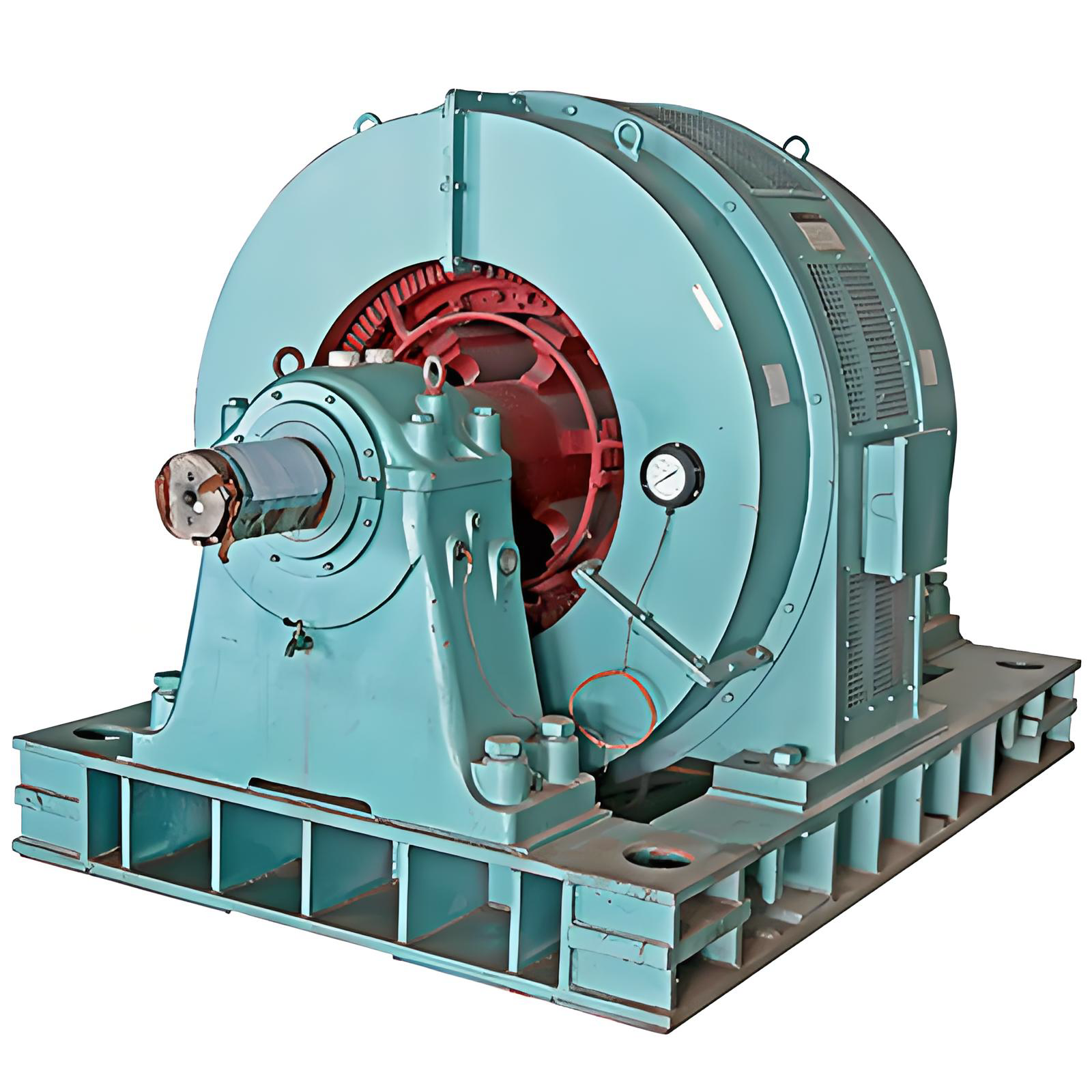

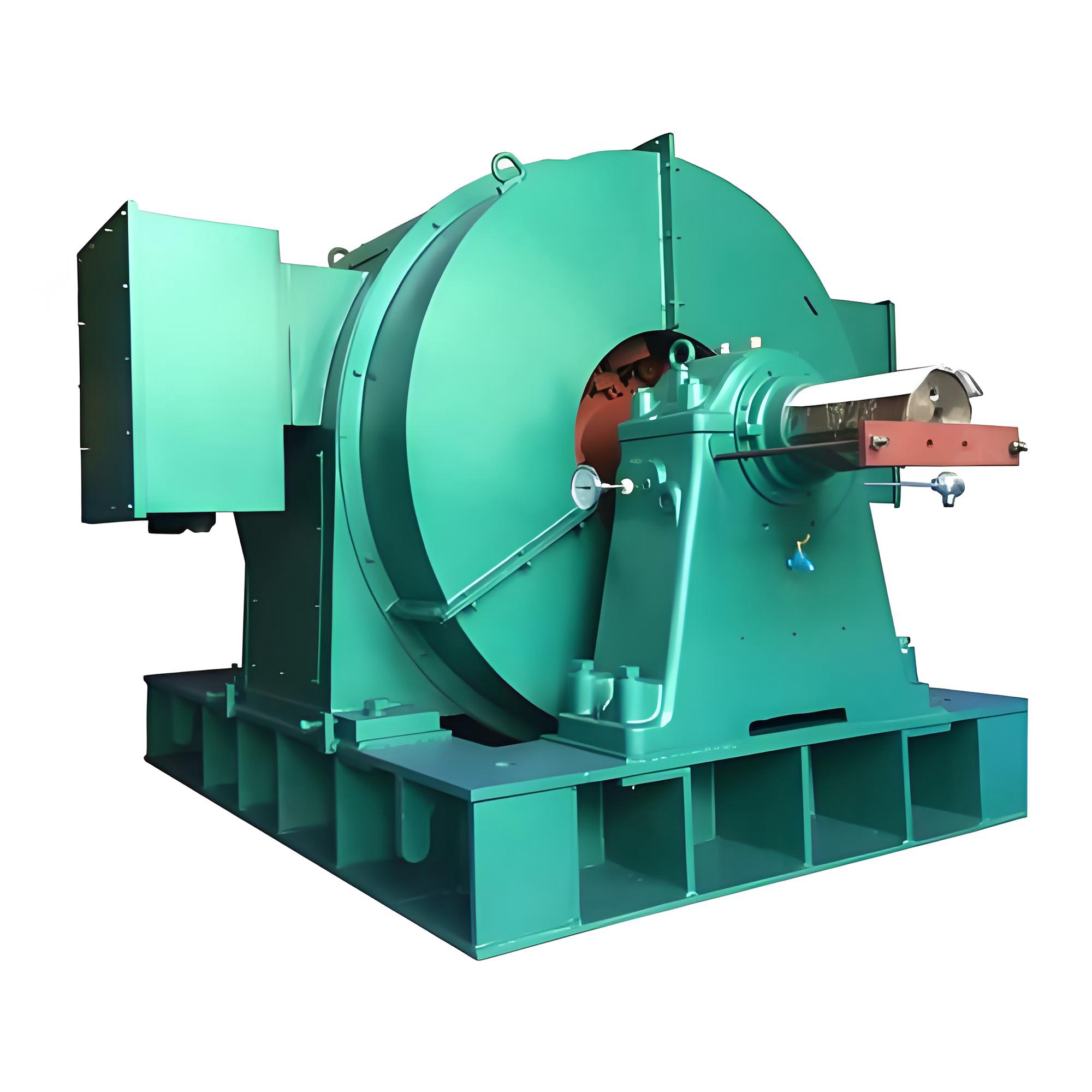

Xi'an TaiFu Xima TDMK Series Large Three-Phase Synchronous Motors are high-performance power units specifically designed for mining milling equipment. Incorporating advanced synchronous motor technology and an optimized cooling system, this series maintains exceptional operational efficiency and outstanding power factor compensation capabilities even under heavy-load conditions. It serves as the ideal power solution for ball mills, rod mills, coal mills, and similar equipment in mining, cement, metallurgy, and other industries.

Article Catalog[Hidden]

- TDMK Series Large Three-Phase Synchronous Motors Professional Guide

- Product Model Analysis: Accurately Identify Motor Specifications

- Product Technology Overview: Professionally designed to meet the needs of mining mills.

- Core Technology Advantages: A Solid Foundation for Exceptional Performance

- Xi'an Simo Motor's Perfect Quality Assurance System

- Selection Guide and Technical Specifications

- Professional Selection Advice

- Ordering Instructions

- concluding remarks

TDMK Series Large Three-Phase Synchronous Motors Professional Guide

High-Efficiency Power Solutions Designed Specifically for Mining Mills

Xi'an TaiFu Xima TDMK Series Large Three-Phase Synchronous Motors are specifically designed forMining Milling EquipmentDesigned for high-performance power systems. This series of motors utilizesAdvanced synchronous motor technology与Optimized cooling systemcan still maintainExceptional operational efficiency和Outstanding power factor compensation capabilityIt has become the ideal power choice for equipment such as ball mills, rod mills, and coal mills in industries including mining, cement, and metallurgy.

Product Model Analysis: Accurately Identify Motor Specifications

The TDMK series of large three-phase synchronous motors follows a standardized naming convention. For example, the model TDMK400-32/1250 is detailed as follows:

- "TDMK" logo: Represents large three-phase synchronous motors specifically designed for mining mill applications.

- "The number "400"Indicates the frame size or specification code of the motor.

- "32-bit: Indicates that the motor has 32 poles.

- "1250 powerThe rated power of the motor is 1250 kW.

The naming system strictly followsNational Standard GB755 "Basic Technical Requirements for Rotating Electrical Machines"和JB8/DQ3449 Technical Specifications for TK Series Large Three-Phase Synchronous MotorsEnsure users can quickly and accurately identify key product parameters.。

Product Technology Overview: Professionally designed to meet the needs of mining mills.

Core technical characteristics

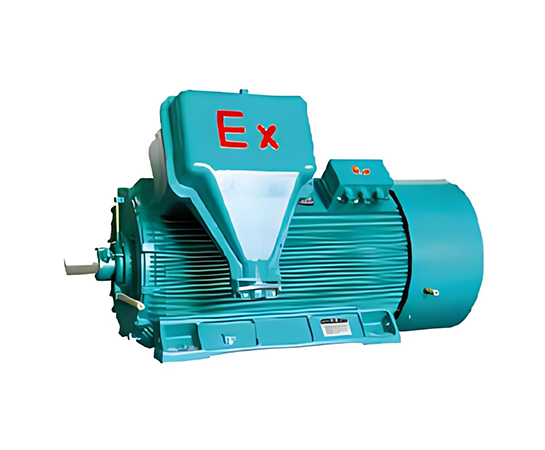

The TDMK series of large three-phase synchronous motors adoptsInnovative Synchronous Motor DesignThe rated voltage is 6000V, and 3000V and 10000V ratings can also be provided upon customer request.This series of motors featuresHigh stall torque, high thermal capacity, reliable performance, adjustable power factorWith significant advantages, it perfectly adapts to the special operating conditions required by mining mills.

Strong environmental adaptability

This series of motors is suitable for use inAltitude not exceeding 1000 meters,Cooling medium temperature shall not exceed 40°C.Operate in indoor environments with minimal dust, no steam, and no corrosive gases such as acids or alkalis.The motor permits full-voltage direct starting. If the user's power grid does not permit full-voltage direct starting, reduced-voltage starting may also be employed.。

Core Technology Advantages: A Solid Foundation for Exceptional Performance

Superior start-up and operational performance

The TDMK series motors featureOutstanding starting characteristicsHigh starting torque enables effortless drive of mining mill load during startup.AdoptThyristor Excitation SystemThe motor's power factor can reach 0.9 (leading), effectively improving power grid quality.。

Innovative structural design

Base: AdoptionWelded from steel platesThe lower part of the motor base houses the motor's output terminals. Its robust construction enables it to withstand the vibrations and impacts inherent in mining equipment.。

StatorThe stator core is made of0.5 mm thick low-loss silicon steel sheetThe stamped fan-shaped sections are stacked, with air duct plates separating the core segments.The windings employ molded double-stacked short-pitch coils, utilizingClass B insulation or Class F insulationTemperature rise is evaluated according to Class B standards to extend service life.。

rotor: Magnetic poles are usedstamped from steel plateThe pole coils are mounted on the rotor yoke together with the pole coils, which feature Class B or Class F insulation.。

Flexible cooling system

The ventilation method for the electric motor isOpen-style natural ventilationor can be made intoFully Enclosed Duct Ventilation SystemUsers can select the most suitable cooling solution based on their actual operating environment.。

Xi'an Simo MotorPerfect Quality Assurance System

Enterprise strength display

Simo motors(Group) Co., Ltd. asA leading enterprise in China's electric motor manufacturing industryThe company specializes in large and medium-sized, high and low voltage, crossDC motorResearch, development, and manufacturingThe company has established a comprehensive industrial chain system, integrating motor design and manufacturing, electrical control, mechanical processing, mold manufacturing, casting processes, and transportation services to provide customers withComprehensive powertrain solutions。

Authoritative certifications and honors

- Quality Management SystemISO 9001 Quality Management System Certification

- Environmental and Safety ManagementISO 14000 Environmental Management System and OHSAS 18000 Occupational Health and Safety Management System Certification

- International product certificationMandatory certifications: European "CE", American "UL", and Chinese "CCC"

- Industry standingChina's Top 500 Machinery Enterprises, Top 100 Electrical Equipment Manufacturers

- Product quality honorQuality and Credit AAA Grade Enterprise, "Ministry, Province and Municipality Famous Brand Product", "Xi'an Inspection-free Product", "China Light Famous Brand Product" and other honorary titles.

Selection Guide and Technical Specifications

Standard configuration parameters

| parameter category | norm |

|---|---|

| Motor Model | TDMK400-32 |

| rating | 400 kW |

| rated voltage | 6000V |

| Rated frequency | 50Hz |

| rated speed | 187.5 rpm |

| Power factor | 0.9 (Ahead of Schedule) |

| protection class | IP00 |

| Cooling method | IC01 |

| Insulation class | Grade F (assessed at Grade B level) |

| Installation form | IM7311 |

Detailed Technical Specifications Table

Based on actual application requirements, the TDMK series offers multiple specifications:

| model number | Rated power (kW) | Rated Voltage (kV) | Rated speed (r/min) | Power factor | Weight (t) |

|---|---|---|---|---|---|

| TDMK350-32 | 350 | 6 | 187.5 | 0.9 | 10.7 |

| TDMK400-32 | 400 | 6 | 187.5 | 0.9 | 11.3 |

| TDMK500-32 | 500 | 10 | 187.5 | 0.9 | 13.7 |

| TDMK630-36 | 630 | 6 | 167 | 0.9 | 13.5 |

| TDMK800-36 | 800 | 6 | 167 | 0.9 | 16.0 |

| TDMK1000-36 | 1000 | 6 | 167 | 0.9 | 16.0 |

| TDMK1250-40 | 1250 | 6 | 150 | 0.9 | 17.7 |

| TDMK1600-36 | 1600 | 6 | 167 | 0.9 | 31.0 |

citation:5

Professional Selection Advice

Application Scenario Analysis

The TDMK series motors are primarily designed for transmission applications.Mining Grinding MillLarge AC three-phase synchronous motors, including:

- Grid-type ball mill

- Rod Mill

- coal mill

Key Selection Considerations

When selecting the appropriate TDMK series large three-phase synchronous motor, it is recommended to focus on the following factors:

- Load CharacteristicsIncluding mill type, starting frequency, load inertia, and impact characteristics

- Grid ConditionsVoltage level, grid capacity constraints, and power factor requirements

- working environmentEnvironmental factors such as ambient temperature, humidity, altitude, and dust concentration

- mounting spaceInstallation Site Dimensions and Ventilation/Heat Dissipation Requirements

- Maintenance requirementsExpected maintenance cycle and maintenance convenience requirements

Special Needs Considerations

- direction of rotationWhen viewed from the slip ring end, rotation is typically counterclockwise, though clockwise rotation can be manufactured upon request.

- Shaft extension loadWhen connecting an electric motor to a grinding machine via a coupling, the motor shaft extension must not bear any externally applied radial or axial forces.

- Qualification methodThe stator leads feature six terminal heads, with high-voltage rubber cables exiting through terminal clamps at the lower section of the frame.

Ordering Instructions

Standard Ordering Information

When ordering TDMK series large three-phase synchronous motors, please specify the following::

- Motor Model

- Rated frequency

- rating

- rated voltage

- extremity

- protection class

- Cooling method

- Installation Type

- direction of rotation[Clockwise direction (as viewed from the motor shaft extension end)]

- Outlet box location[Right side of the motor (when facing the motor shaft extension end)]

Special Order Requirements

If you have any of the following special requirements, please clearly indicate them when placing your order:

- Dual shaft extensions, special cable outlet box positioning, counter-rotating shafts

- Specialized models for humid tropical or outdoor corrosion-resistant environments

- Special bearing structures or lubrication methods

- Other special technical parameters or configuration requirements

concluding remarks

Xi'an TaiFu Xima TDMK Series Large Three-Phase Synchronous Motors, with theirProfessional technical design、Excellent performance和Reliable operating qualityIt has become the preferred power solution for grinding mill equipment in numerous mining industries.Xima Electric leverages its robust technical expertise and comprehensive service system to provide every customer withProfessional technical support和Timely after-sales serviceSafeguard。

For detailed information on the technical specifications of the TDMK series large three-phase synchronous motors or to obtain personalized selection recommendations, please contact the professional technical team at Xima Motors. We are committed to providing you with comprehensive service support.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206