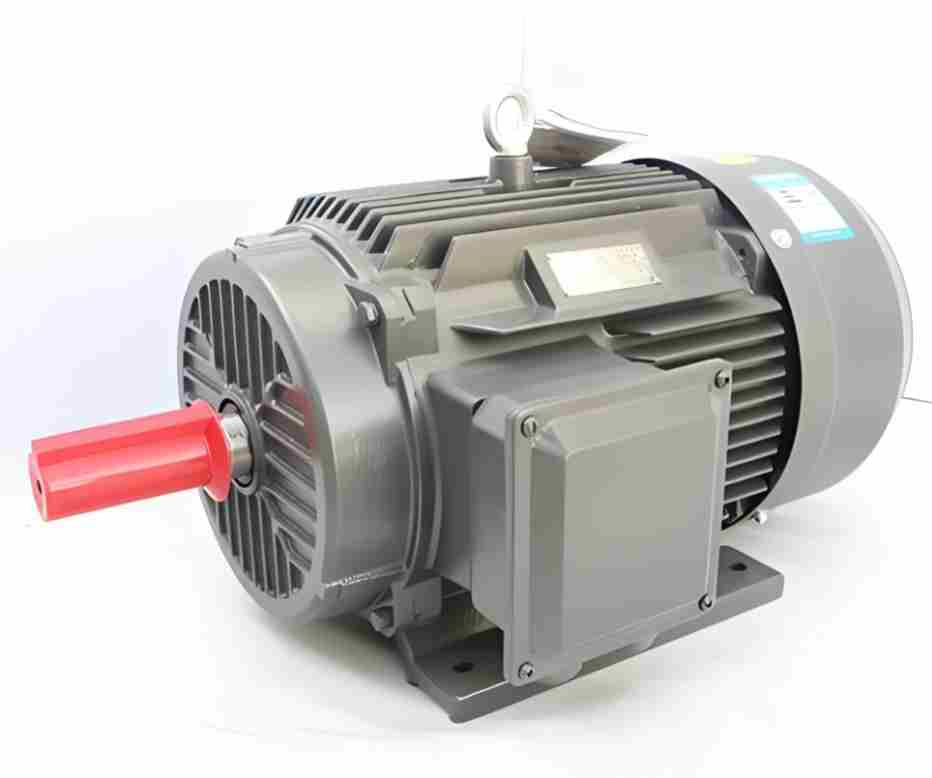

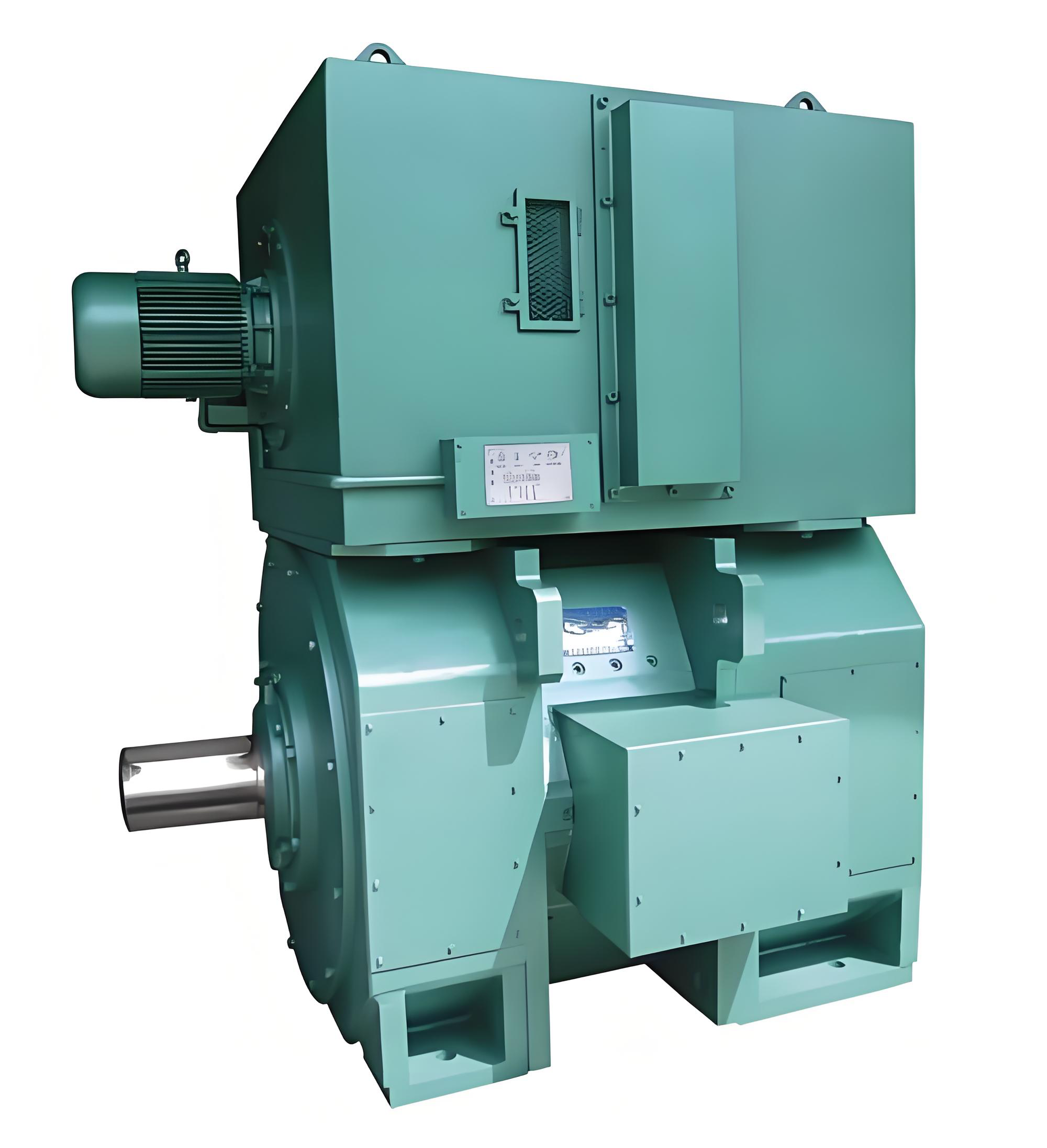

Energy-saving high-voltage motor manufacturer Sigma Motor

Sigma Motor is a manufacturer specializing in energy-efficient high-voltage motors and is committed to providing customers with efficient and reliable motor solutions. As a leader in the industry, Sigma Motors utilizes advanced technology and quality materials to ensure that its products meet international standards for energy efficiency and performance. Why choose energy-efficient high-voltage motors from Sigma motors? High energy efficiency: Sigma's high-voltage motors use advanced design and efficient production processes to effectively reduce energy consumption

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206