Article Catalog[Hidden]

- Y series IP23 low-voltage three-phase asynchronous motor comprehensive analysis

Y Series IP23 Low Voltagethree-phase asynchronous motorcomprehensive analysis

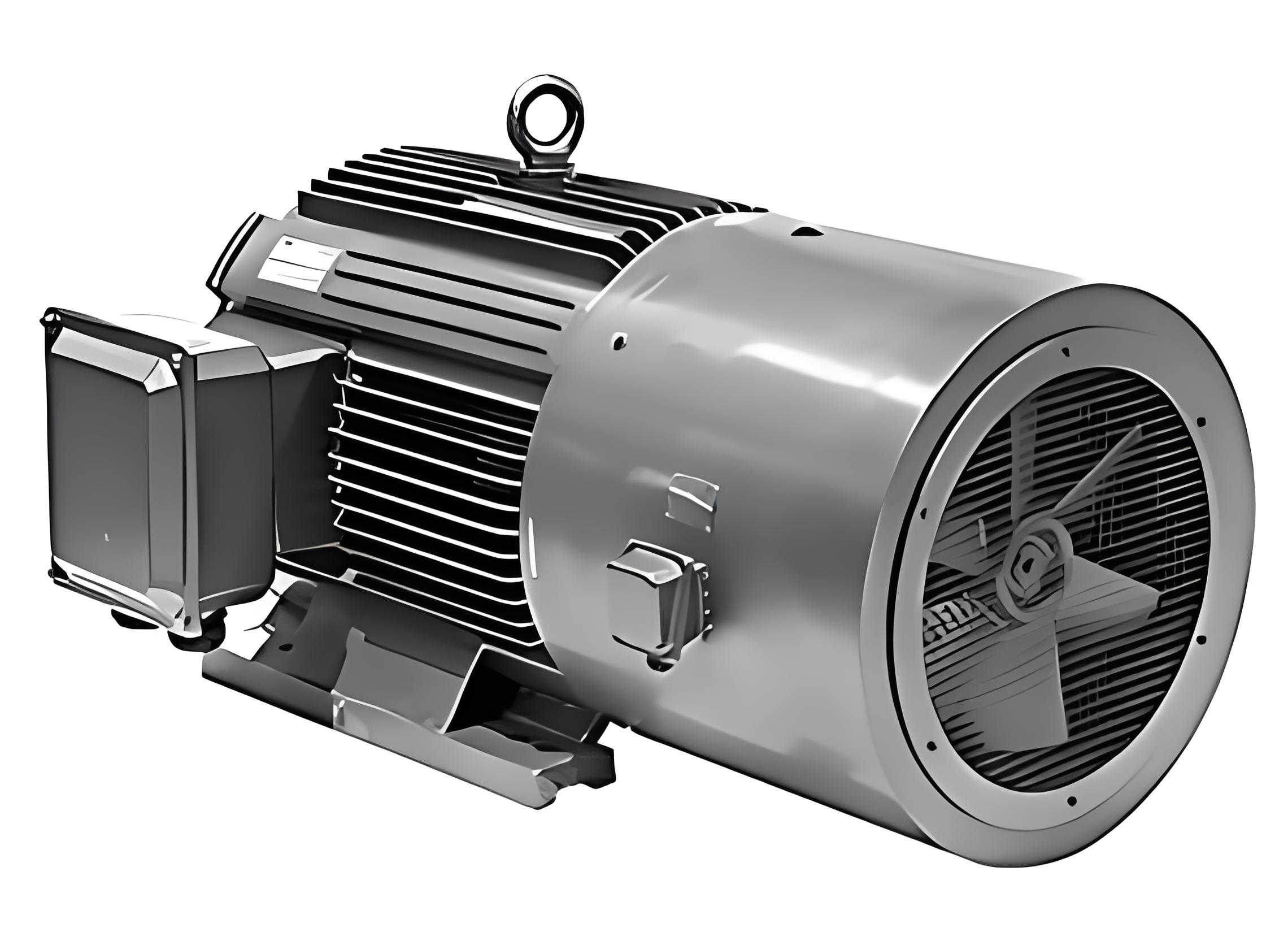

In the field of industrial power transmission, Y series IP23 low-voltage three-phase asynchronous motor with itsExcellent protection和Stable operating characteristicsIt has become the ideal power unit for general-purpose equipment in various industries.

I. Product overview and technical characteristics

1. Product profile

Y series IP23 low-voltage three-phase asynchronous motors areChina's unified design of energy-saving motor seriesAdoptionProtected cage rotor constructionThe rated voltage is380 voltsThe rated frequency is50 hertz. The power range of this series of motors is from5.5 kW to 132 kWTotal14 power levels, 6 seat numbers and 45 sizesIt is capable of meeting the power requirements of different industrial scenarios.

Unlike fully enclosed IP44 motors, IP23 motors utilize aProtected construction designIts enclosure protection level can bePrevent fingers from touching electrically charged conductors or rotating parts of the enclosure.The same time can bePreventing the entry of small solid foreign bodies larger than 12 mm in diametermergePrevents dripping of water at an angle of 60 degrees or less along a vertical line into the motor.. This protective structure is more superior than the traditional anti-drip structure, making the motor operation more safe and reliable。

2. Core technical characteristics

Y series IP23 motors incorporate a number of innovative technologies with significant performance advantages:

- Highly efficient electrical characteristics: The electric motor utilizesClass B insulationThe windings are all△shaped connectionThe cooling method isIC01 (self fan cooling). itsPower ratings and installation dimensions in accordance with International Electrotechnical Commission (IEC) standardsThe introduction of the equipment has facilitated the matching and maintenance of the introduced equipment.

- Excellent start-up performance: This series of motors hasCharacterized by high starting torqueIt can easily drive heavy load equipment to start, solving the problem that ordinary squirrel-cage motors have excessive current and insufficient torque during heavy load starting.

- Rugged structural design: The electric motor utilizesOptimized mechanical structureIt can withstand mechanical and thermal stresses under various working conditions to ensure long-term stable operation.

Technical parameters and performance indicators

Y series IP23 low-voltage three-phase asynchronous motors cover a wide range of technical specifications to meet the power requirements of different industrial scenarios. The following are the main technical parameters of this series of motors:

Table: Y series IP23 motor main technical parameters

Description of performance characteristics

Y series IP23 motor inOperational performance and productivityExcellent performance in all areas:

- high efficiency and energy saving: Higher level of motor efficiency, compared to the conventional J02 series.Significant improvement in performanceThe energy saving effect is remarkable

- Low vibration and low noise: AdoptionOptimized design and precision manufacturing processesThe motor runs smoothly with low vibration and low noise.

- Wide Voltage Adaptability: the ability toGrid voltage fluctuationsStable performance under all conditions, adapting to various grid environments

III. Structural design and configuration

1. Motor body structure

Y series IP23 low-voltage three-phase asynchronous motors adopt theProtected construction designEach component is carefully designed and optimized:

- Protective housing design: The protection class of the motor isIP23This construction is different from the fully enclosed construction of IP44, but theSuperior to normal drip-proof construction. The housing effectively prevents foreign objects from harming the motor and the human body, while facilitating heat dissipation

- Stator structure: The stator winding is made ofClass B insulationReliable insulation and long life. The winding part has a reliable fixing and is treated with dipping paint, which has reliable electrical and mechanical strength, and is sturdy and durable.

- Rotor construction: AdoptionCage rotor structureThe rotor is made ofHigh-quality materials和Precision Manufacturing ProcessEnsure smooth and reliable motor operation

2. Cooling system

Y series IP23 motor adoptsIC01 Cooling Method(Self-fan cooling), through the internal fan to form air circulation, effectively take away the heat generated by the motor, to ensure that the motor continues to run stably under the rated load.. This cooling structure is simple, reliable and easy to maintain.

IV. Application areas and scenarios

Y series IP23 low-voltage three-phase asynchronous motors are widely used in many industrial fields due to their excellent protection performance and high efficiency and energy saving:

1. Heavy industry

- Mining industry: for drivingCrushers, winches, hoistsHeavy-duty equipment, such as heavy-duty equipment, to withstand harsh working conditions

- Metallurgical industry: Applied toRolling mills, compressorsand other equipment, providing reliable power support

- Power industry: forpower plantsof various auxiliary equipment, such asFans, pumps等

2. General industrial areas

- Compressor and pump equipment: Applicable toCompressors, pumpsand other equipment, providing efficient power solutions

- transmission mechanism: Applied toConveyor belts, transportation machineryMaterial handling equipment to meet the needs of continuous operation

- cutting machine: for all kinds ofMachine ToolsThe drive provides a stable power output

3. Special application scenarios

Y series IP23 motors are especially suitable for the following special working conditions:

- Needs good heat dissipationThe protective structure of the product makes it ideal for all types of applications.

- Relatively clean environmentindustrial site

- Requires regular maintenance checksspecifications

V. Product Advantages and Values

1. Operational reliability

Y series IP23 motors offer significant advantages in terms of reliability:

- Rugged structural design: AdoptionProtected constructionIt can withstand mechanical and thermal stresses under various working conditions to ensure long-term stable operation.

- High-quality insulation systems: AdoptionClass B insulationReliable insulation and long life

- Good environmental adaptability: The motor is suitable for use at altitudes ofNot exceeding 1000mAmbient TemperatureNot more than 40°CContinuous operation in the environment of

2. Energy efficiency economics

Y series IP23 motors have significant economic benefits:

- Reduced operating costs: High-efficiency design can beSignificant reduction in energy consumptionReduced payback period

- Optimizing energy use: The motor hasHigher power factor and efficiencyImprovement of grid quality

- Low life cycle costs:Long life design和Low maintenance requirementsDramatic reductions in total life cycle costs

3. Ease of maintenance

This series of motors has been designed with ease of maintenance in mind:

- Maintenance-friendly structural design: Protected construction makes routine inspection, maintenance and overhaul easier.

- modular design: Modularized design of key components to reduce maintenance difficulties and spare parts inventory

- Long life design: AdoptionQuality Insulation SystemsLong design life, long maintenance intervals

VI. Installation and use guide

1. Installation environmental requirements

Y series IP23 low-voltage three-phase asynchronous motors have clear requirements for the installation environment:

- environmental conditions: Suitable for use at altitudeNot exceeding 1000mAmbient temperatureNot more than 40°CContinuous operation in the environment of

- humidity condition: Relative humidity of ambient air meets standard requirements

- mounting position: Ensure adequate space around the motor for cooling ventilation and maintenance

2. Installation and commissioning

Correct installation and commissioning is the key to ensure the safe operation of the motor:

- basic requirement: RequiredStrong and level foundationThe motor is designed to withstand the weight of the motor and the mechanical stresses of operation.

- alignment requirements: When the motor and driven machinery are connected by couplings, it must be ensured thatPrecise alignmentAvoidance of additional forces

- electrical connection: Properly wire the motor in accordance with the motor nameplate and wiring diagram to ensure that thereliable grounding

VII. Services and technical support

1. Quality assurance systems

Y series IP23 low voltage three-phase asynchronous motors are manufactured following strict quality standards:

- standards compliance: The products strictly follow theJB/T 5271-2010National and industry standards

- Strict testing process: In the manufacturing process afterMultiple rigorous testsEnsure that the performance of the product meets the requirements of the standard

- Comprehensive performance testing: Each motor isRigorous factory testingEnsure reliable product quality

2. After-sales service commitments

Simo motorsProvide customers with comprehensive after-sales service guarantee:

- Professional Technical Support: Provide professional consulting services for product selection and installation guidance

- Rapid Response Mechanism: Respond to and resolve customer issues in a timely manner upon receipt of after-sales service requests

- Ongoing services: Provide customers with long-term technical support and service guarantee

Y series IP23 low-voltage three-phase asynchronous motor with itsExcellent protective properties、Highly efficient energy-saving features和Reliable operational performanceIt has become the industrial powerhouse of theIdeal Solution. ByContinuous technological innovation和Strict quality controlSimo Motors ensures that every Y-Series IP23 motor isHarsh industrial environmentssubscribeSafe, stable and efficientThe power of the support.

Choosing Y series IP23 low-voltage three-phase asynchronous motor is choosingReliable equipment performance和Complete technical servicesWe are looking forward to cooperating with you. We are looking forward to cooperating with you to jointly promote the progress and development of energy-saving technology in the industrial field.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206