Article Catalog[Hidden]

- YBK3 Series Explosion-Proof Three-Phase Asynchronous Motors for Underground Coal Mines: A Safe and Efficient Power Solution for Mining Operations

YBK3 Series Explosion-Proof Type for Underground Coal Minesthree-phase asynchronous motorSafe and Efficient Mining Power Solutions

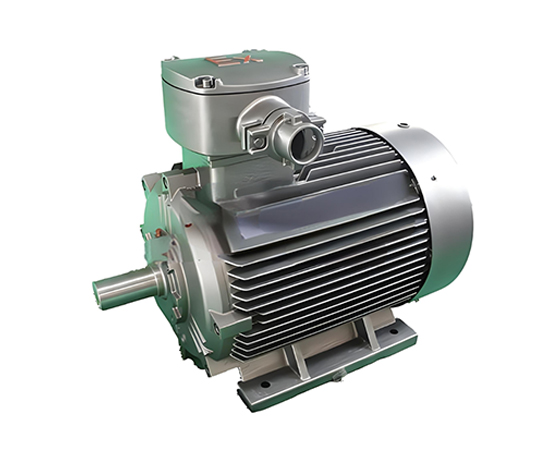

In the coal mining sector, the YBK3 series explosion-proof three-phase asynchronous motors are characterized by theirOutstanding explosion-proof performance和Efficient Energy Utilizationbecoming an indispensable power unit in underground working environments.

YBK3 Series Explosion-proof Three-phase Asynchronous Motors for Underground Coal MinesSpecifically designed for underground coal mining conditionsHigh-efficiency Energy-saving Explosion-proof Power EquipmentThis series of motors adoptsAdvanced flameproof technology and optimized electromagnetic designpossessExplosion-proof safety, high efficiency, reliable operation, long service lifefeatures, strictly adhering toGB 3836.1-2010 "Explosive Atmospheres - Part 1: Equipment - General Requirements" 和GB 3836.2-2010 Explosive Atmospheres - Part 2: Equipment Protected by Flameproof Enclosures "d" Compliant with national standards, it serves as the ideal power solution for underground mining and excavation workfaces and fixed equipment drives.。

I. Product overview and technical characteristics

1. Product Positioning and Scope of Application

The YBK3 series explosion-proof three-phase asynchronous motors are specifically designed forHarsh working conditions in coal mine shaftsCustom-designed motorIts explosion-proof rating isExd I MbApplicable toUnderground coal mining workface containing gas or coal dustand other hazardous locations where explosive gas mixtures are present。

This series of motors in the YBK2Explosion-proof motorsDeveloped based on the foundation of current domestic advanced electromagnetic technology, it featuresHigh efficiency, energy-saving, long service life, excellent performance, low noise, and advanced explosion-proof designSignificant advantagesThe motorThe base frame is fabricated from steel plate welded together.The fan hood, junction box, and insulating structure have all been reinforced to withstand the harsh working conditions of underground coal mines.。

2. Core technical characteristics

The YBK3 series motors incorporate multiple innovative technologies and offer significant performance advantages:

- Highly efficient explosion-proof designThe motor's explosion-proof structure is advanced. When an explosive mixture inside the motor detonates,The explosion-proof enclosure shall not be damaged or deformed in a manner that affects its explosion-proof performance.Internal explosion flames shall not cause external explosions through explosion-proof joints.

- Outstanding efficiency performanceThe motor efficiency indicators meet the requirements.GB18613-2012 "Energy Efficiency Limit Values and Energy Efficiency Grades for Small and Medium-Sized Three-Phase Asynchronous Motors" Class 2 energy efficiency rating, andIE3 Efficiency Class per IEC 60034-30Quite so, with significant energy-saving effects.

- Robust mechanical constructionThe motor housing achieves an IP rating ofIP55effectively prevents dust and moisture from entering the motor interior, with an insulation rating ofFThe stator winding has a large temperature rise margin and a long service life.

Technical parameters and performance indicators

The YBK3 series explosion-proof three-phase asynchronous motors offer comprehensive technical advantages. Below are their primary technical specifications:

Description of performance characteristics

The YBK3 series motors areExplosion-proof safety, operational performance, and energy efficiencyExcellent performance in all areas:

- high efficiency and energy savingMotor efficiency complies withLevel 2 Energy Efficiency in GB18613-2012 StandardRequirements, in line with international standardsIE3 Efficiency ClassSignificantly reduces operational energy consumption.

- Low noise, low vibration: AdoptionOptimized design and precision manufacturing processesThe motor runs smoothly.The rotor and bearing system has been specially optimized.Vibration and noise levels are significantly lower than those of traditional explosion-proof motors.

- Wide Voltage AdaptabilityAvailable in multiple voltage specifications, capable of operating atDifferent power grid environments in coal mine shaftsMaintain stable performance

III. Structural design and configuration

1. Motor body structure

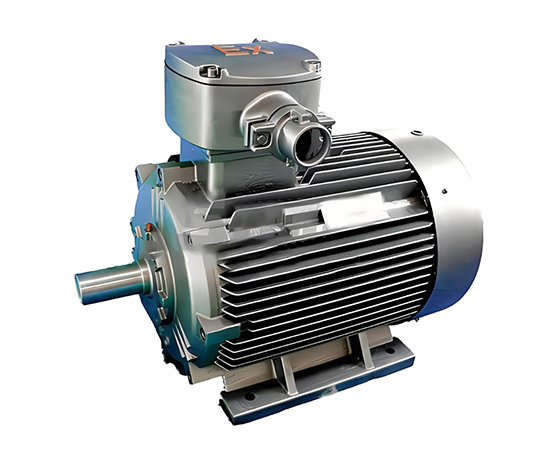

The YBK3 Series Explosion-Proof Three-Phase Asynchronous Motor adoptsProfessional Explosion-Proof DesignEach component is carefully designed and optimized:

- Explosion-proof enclosure design: Components of the explosion-proof enclosure for electric motors, such asBase, end cover, bearing inner cover, terminal box cover, terminal box baseAfter finishing, it must undergo1.5 MPa, duration of at least 10 secondsThe static pressure test shall be considered satisfactory if no water leakage occurs and the enclosure exhibits no permanent deformation or damage that affects its explosion-proof configuration.

- Heat Dissipation Structure Optimization: AdoptionBase with parallel and vertical cooling finsFully enclosed self-ventilated structure,The fan is made of anti-static plastic material.Its low rotational inertia and minimal energy loss, coupled with a steel plate housing, ensure effective protection against foreign object intrusion while maintaining operational efficiency.Maximum ventilation volumeExcellent heat dissipation performance

- Explosion-Proof Junction Box DesignThe junction box is located at the top of the motor. It features a large cavity for convenient wiring and includes a separate compartment for installing cable glands.The methods of incoming power supply include:Rubber-sheathed cable, armored cable, steel conduit wiring, flexible conduitInside the junction boxSix terminal blocks

2. Internal Core Components

The internal structure of the YBK3 series motors has been meticulously designed and optimized to ensure efficient and safe operation:

- Stator structure:The stator windings are constructed using high-strength polyester-enameled round copper wire and undergo VPI vacuum pressure impregnation., forming a complete unit, the winding insulation exhibits excellent electrical, mechanical, moisture-proof properties, and thermal stability.

- Rotor design:The rotor features a cast aluminum construction.The rotor has undergone dynamic balancing calibration, ensuring smooth motor operation with minimal vibration levels.。Stator and rotor laminations utilize high-permeability, low-loss premium electrical silicon steel sheets.Low motor losses, high efficiency

- Bearing SystemFor bearingsYBK3 Low-Vibration, Low-Noise Bearings for Explosion-Proof MotorsFor frame numbers 132 and below, double-sealed bearings are used, with wave spring washers installed at the shaft extension end to apply moderate pressure against the bearings.For frame sizes 160 and above, an inner and outer cover structure is employed, with the bearing area axially secured by a retaining ring, effectively preventing axial movement of the motor rotor.The bearing assembly is installed withNote: Oil-drain device allows for adding bearing grease without shutting down the machine.

IV. Application areas and scenarios

The YBK3 series explosion-proof high-efficiency three-phase asynchronous motors are widely used in the coal mining industry due to their reliable explosion-proof performance and high energy efficiency:

1. Underground mining equipment

- Mining equipment: forUnderground Mining Machinery for Coal Mine WorkingsThe drive is a dedicated motor specifically designed for these devices.

- Fixed equipment:Suitable for use in coal mine shaftsFixed equipmentsuch as pumps, ventilation equipment, etc.

- Transportation machinery:For use in coal mine shaftsConveyors, hoistsand equipment, providing reliable explosion-proof power

2. Applicable Environmental Conditions

The YBK3 series motors have clearly defined operating environment requirements:

- environmental temperature: The ambient air temperature is at least-15°C, with the highest being35°C(Underground coal mine)

- altitudeInstallation AltitudeNot exceeding 1000m

- humidity conditionThe maximum relative humidity of ambient air shall not exceed95%(At a temperature of 25°C)

- Power conditionsVoltage Fluctuations±5%(Short-term allowable fluctuation ±10%); frequency fluctuation±2%(Temporary fluctuations within ±5%)

V. Product Advantages and Values

1. Safety and Reliability

The YBK3 series explosion-proof three-phase asynchronous motors offer significant advantages in terms of safety:

- Reliable explosion-proof performance: Strictly in accordance withNational Explosion-Proof StandardsDesigned and manufactured with advanced explosion-proof construction to ensure safe operation in explosive environments.。All bolts connecting the explosion-proof enclosure are fitted with spring washers.to prevent self-loosening, and the fastener's clamping force is greater than or equal to640 MPa

- High-Quality Materials and Manufacturing: The key components are adoptedQuality materials和Precision Manufacturing ProcessEnsure long-term stable operation of the motor. Under rated operating conditions,The maximum surface temperature of the motor housing shall not exceed +150°C.The temperature outside the cable entry point shall not exceed the permissible temperature of the cable used.

- Comprehensive safety protection:Can be provided according to user requirements.Stator Temperature Monitoring, Bearing Temperature Monitoring, Stator Moisture ProtectionProtective devices, available for H160 and larger motorsNon-stop refueling systemfurther enhance operational safety

2. High-efficiency energy-saving benefits

The YBK3 series motors offer significant economic benefits:

- Reduced operating costs: High-efficiency design can beSignificant reduction in energy consumption, shortening the payback period. The rated power range of the motor is from0.75 kW to 315 kWto meet different power requirements

- Optimizing energy use: The motor hasHigher power factor and efficiencyImprove grid quality and reduce investment in reactive power compensation equipment.

- Low life cycle costsAlthough the initial investment may be slightly higher,Energy-saving benefits during operation and low maintenance costsDramatic reductions in total life cycle costs

3. Ease of maintenance

This series of motors has been designed with ease of maintenance in mind:

- Maintenance-friendly structural designReasonable structural design facilitates routine inspections, maintenance, and repairs.The bearing area is equipped with an oil injection and drainage device, enabling grease replenishment without stopping the machine.

- modular design: Modularized design of key components to reduce maintenance difficulties and spare parts inventory

- Long life design: AdoptionClass F insulation systemRated for Class B temperature rise, with ample temperature rise margin, extended design life, and longer maintenance intervals.

VI. Installation and use guide

1. Installation environmental requirements

The YBK3 series explosion-proof three-phase asynchronous motors have specific requirements for the installation environment:

- environmental conditions: Applicable toUnderground coal mines containing gas or coal dustEnvironment, especiallyMining Face

- altitudeInstallation AltitudeNot exceeding 1000m(except for high-altitude motors)

- mounting position: Electric motorThe main junction box is located on the top of the base and can rotate left or right.Meet users' requirements for different cable outlet configurations

2. Installation and commissioning

Proper installation and commissioning are critical to ensuring the safe operation of the motor:

- basic requirement: RequiredStrong and level foundationThe motor is designed to withstand the weight of the motor and the mechanical stresses of operation.

- transmission method:Permitted to adoptFlexible couplings, spur gears, and belt pulley drives

- direction of rotationClockwise (default), counterclockwise (specify in order)

- Startup Method:Direct-on-line starting, Y/Δ starting, reduced-voltage starting, variable-frequency startingMultiple startup methods available

VII. Services and technical support

1. Quality assurance systems

The production of YBK3 series explosion-proof three-phase asynchronous motors adheres to stringent quality standards:

- standards compliance: The products strictly follow theGB 755-2008 "Rated Values and Performance of Rotating Electrical Machines"、GB 3836 Series Explosion-Proof Standardsand other relevant standard requirements

- All certifications are complete: In addition to meeting national standards, it also complies withIEC 79-1, BS 4683, and EN 50018the provisions

- Strict testing process: In the manufacturing process afterMultiple rigorous testsEnsure that the performance of the product meets the requirements of the standard

2. After-sales service commitments

The supplier provides customers with comprehensive after-sales service support:

- Professional Technical Support: Provide professional consulting services for product selection and installation guidance

- rapid responseIf customers encounter quality issues during use, the supplier will respond promptly.

- Ongoing services: Provide customers with long-term technical support and service guarantee

The YBK3 Series Explosion-Proof Three-Phase Asynchronous Motors for Underground Coal Mines, with theirOutstanding explosion-proof performance、Highly efficient energy-saving features和Reliable operational performancehas become the industrial power solution for hazardous environments in coal mine shafts.Ideal Solution. ByContinuous technological innovation和Strict quality controlEnsure that every YBK3 series explosion-proof three-phase asynchronous motor can operate inHarsh coal mine environmentsubscribeSafe, stable and efficientThe power of the support.

Choosing the YBK3 series explosion-proof three-phase asynchronous motors for underground coal mines means choosingReliable security assurance和Complete technical servicesWe look forward to collaborating with you to advance safety production and energy-saving technological progress in the coal mining industry.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206