Excerpt:

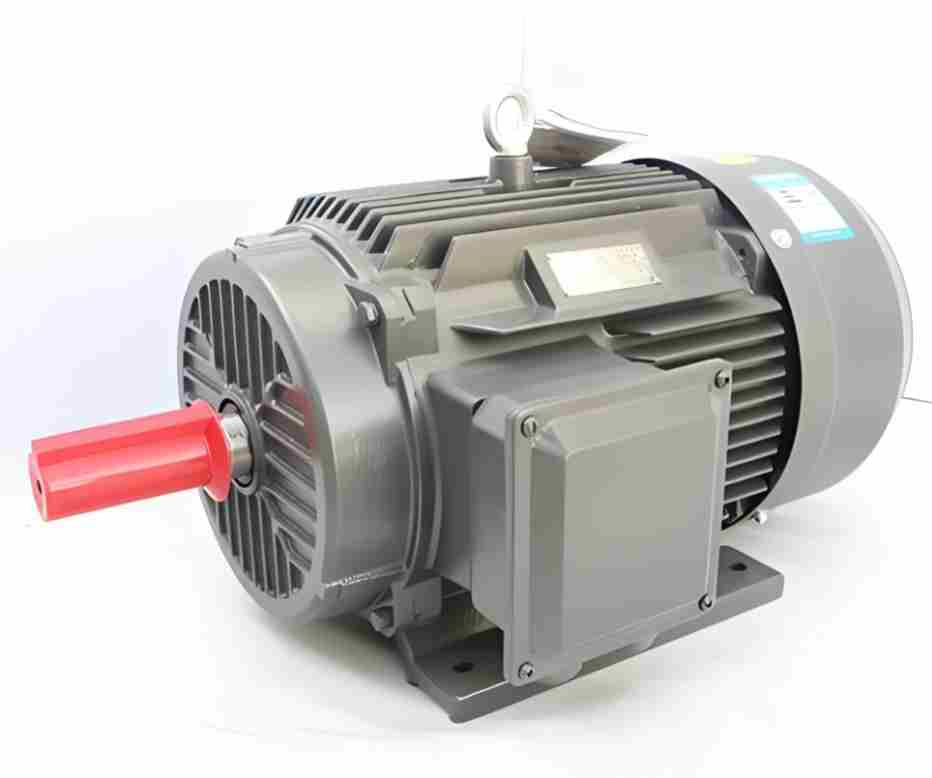

Simo Motor ZDB series motor for oil pumps is a high-performance motor based on advanced electromagnetic design and precision manufacturing technology, optimized for oil pump systems and other fluid conveying equipment. This series of motors combines the core advantages of high energy efficiency, low noise operation and high protection level, and is widely used in industrial pump equipment, hydraulic systems, water supply and drainage engineering, petrochemical and machinery manufacturing fields. The design complies with IEC international standards and domestic energy-efficiency norms, and supports a variety of voltage and frequency adaptations to meet the needs of industrial power consumption in different regions.

Article Catalog[Hidden]

- Simo Motors ZDB series motors for oil pumps: industrial solutions for energy-efficient and reliable drives

Simo motorsZDB series motors for oil pumps: industrial solutions for energy efficient and reliable drives

I. Product overview: motor core designed for oil pump systems

Simo motorsZDB series motor for oil pumpIt is a high-performance motor based on advanced electromagnetic design and precision manufacturing technology, optimized for oil pumping systems and other fluid transfer equipment. This series of motors incorporatesEnergy efficient, low noise operation, high protection levelThe core advantages, such as widely used in industrial pump equipment, hydraulic systems, water supply and drainage engineering, petrochemical and machinery manufacturing fields. Its design conforms toIEC international standardsWith the domestic energy-efficiency norms, support a variety of voltage and frequency adaptation, to meet the needs of different regions of industrial power consumption。

ZDB series motors useTotally enclosed self-cooling structure(Protection class IP54/IP55), effectively preventing oil, dust and moisture intrusion, extending the service life of the motor in harsh environments. At the same time, the motor insulation system adoptsClass H insulationThe windings are treated with vacuum pressure impregnation to ensure excellent insulation strength and mechanical stability under high temperature and high humidity conditions.。

II. Core technology features and performance advantages

1. Energy efficiency and energy optimization

- ZDB series motors useHigh permeability silicon steel sheet coreWith low-loss winding design, it significantly reduces iron and copper losses and achieves the energy efficiency level ofIE3/IE4 standards(Optional), the operating efficiency is increased by 5%-10% compared with ordinary motors, which effectively reduces the long-term energy cost.。

- Highly matched with the pump load characteristics, to avoid the phenomenon of “big marat small car”, to realize theSystem-level energy efficiency improvements。

2. Low vibration and silent operation

- Rotor balancing accuracy up toG2.5Above, with optimized bearing system and structural rigidity design, the vibration and noise control in the industry leading level (noise limit value in line with GB/T 10069 standard), especially suitable for indoor or confined space with strict requirements on environmental noise.。

3. Wide Voltage Adaptability and Multiple Protection

- be in favor of220V/380V/660VMulti-voltage level (can be customized upon request), adapts to 50Hz/60Hz grid frequency, and has the ability toOverload, phase loss and blocking protectionFunction, built-in thermal protection device, to avoid motor burnout caused by abnormal current。

- Bearing seals are made ofOil Leakage Resistant DesignThe shaft extension is fitted with an oil seal as standard to prevent lubricant leakage and contamination of the pump medium.。

4. Compact and easy maintenance

- The motor body is made ofLightweight aluminum/cast iron housingCompact structure and excellent heat dissipation, mounting dimensions in accordance with the IEC standard interface, can be a direct replacement for similar models.。

- furnishIMB3 (horizontal), IMB5 (vertical), IMB35 (vertical and horizontal) A variety of installation methods, such as to adapt to the space layout of different pumps.。

Application Scenarios and Industry Solutions

ZDB series motors are optimized for the following scenarios to ensure stable operation and long life:

- Industrial Pump SystemsCentrifugal pumps, whirlpool pumps, self-priming pumps for water supply pressurization, circulation cooling, media transfer, and other applications.。

- Hydraulic transmission equipment: Reliable power supply for hydraulic station pumps, suitable for machine tools, presses, and construction machinery.。

- Petrochemicals and EnergyCorrosion-resistant design is compatible with mildly corrosive media, used for oil transfer, chemical process pumps。

- Environmental protection and water treatment: Matching drainage pumps, booster pumps, excellent performance in sewage treatment, river pumping and drainage。

Fourth, the technical parameters of the selection guide

| parameter category | Range of specifications and options |

|---|---|

| rating | 0.37kW~45kW (0.5HP~60HP) |

| Number of Poles and Rotation Speed | 2-pole (2900r/min), 4-pole (1450r/min), 6-pole (960r/min) |

| Voltage and Frequency | 220V/380V/415V/660V, 50Hz/60Hz |

| protection class | IP54 (dustproof and waterproof), IP55 (high-pressure water jet protection) |

| Insulation class | Class F or H (high temperature resistance 155°C~180°C) |

| Installation | International standards such as IMB3, IMB5, IMB35, etc. |

| Cooling method | IC411 (self-cooling) |

| environmental adaptation | Altitude ≤1000m, ambient temperature -15℃~40℃, humidity ≤90% |

Note: For specific model parameters, please refer to the official technical manual of Simo Motors or contact technical support for customization.。

V. Selection and installation recommendations

- power matching: According to the shaft power of the pump and the characteristics of the starting load, select the motor model with a margin of 10%~15% reserved for the rated power.

- environmental adaptationHigh-temperature or dusty environments are recommended to choose H-class insulation with IP55 protection; corrosive places need to customize the surface anti-corrosion treatment.

- Installation and maintenance:

- Ensure the rigidity of the foundation bracket, and correct the coaxiality between the shaft extension and the pump body (error ≤ 0.1mm).

- Regularly clean the cooling ducts and check the lubrication status of the bearings (recommended to replenish grease every 4000 hours of operation).

VI. Why choose Simo ZDB series?

- Quality CertificationPassed ISO9001 quality management system, CE certification and energy efficiency labeling certification.。

- Long-term reliabilityDesigned to last over 100,000 hours, with a 2-year warranty on bearings and windings.。

- Customized servicesVoltage, flange interface, explosion-proof class (Ex dI/Ex dII) and other customizations are supported.。

- Full-cycle supportProvide one-stop technical service from selection, installation and commissioning to maintenance training.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206