Article Catalog[Hidden]

- Simo ZTP Railway Motors: Reliable Power Source for Locomotive Operation

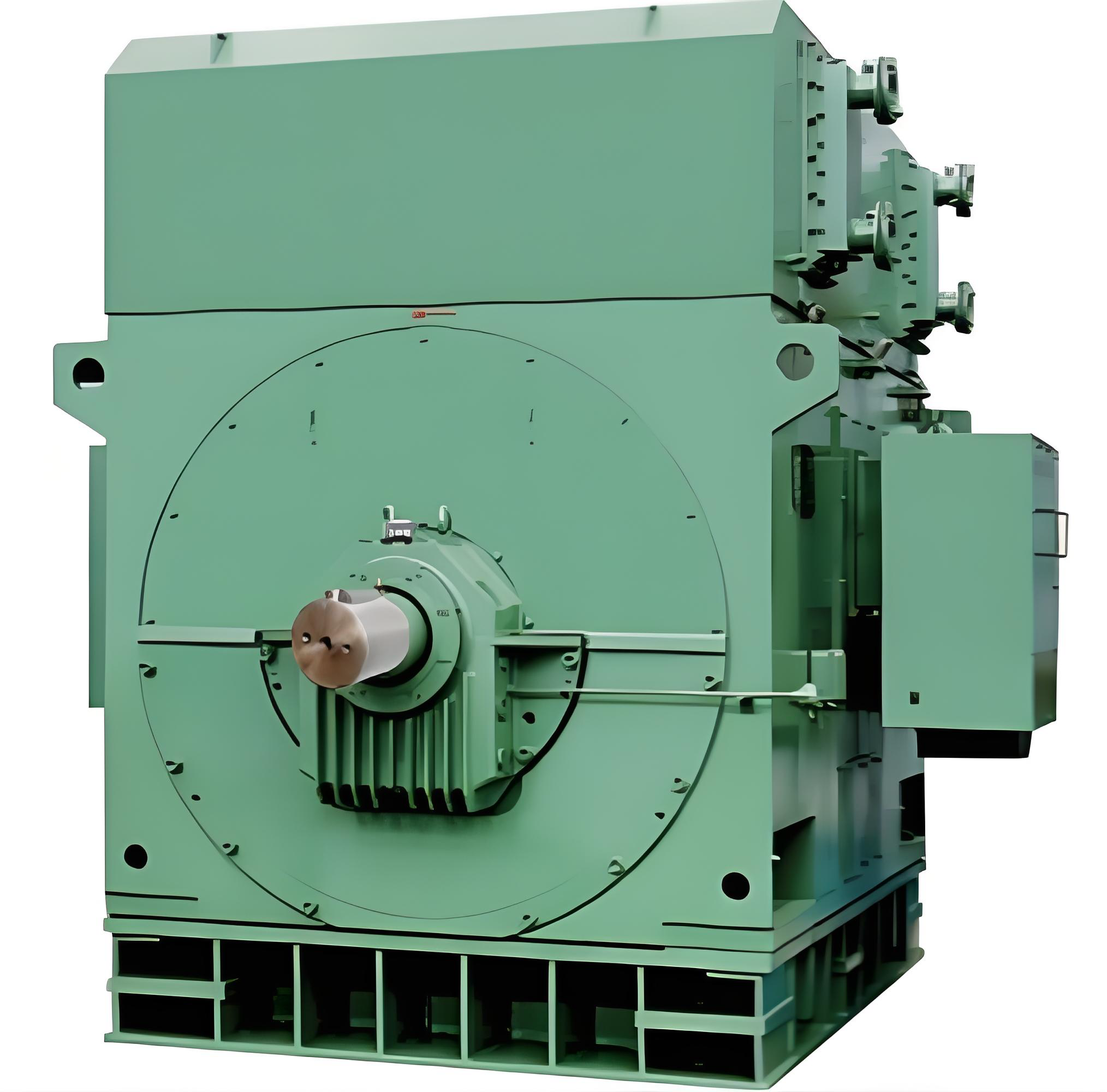

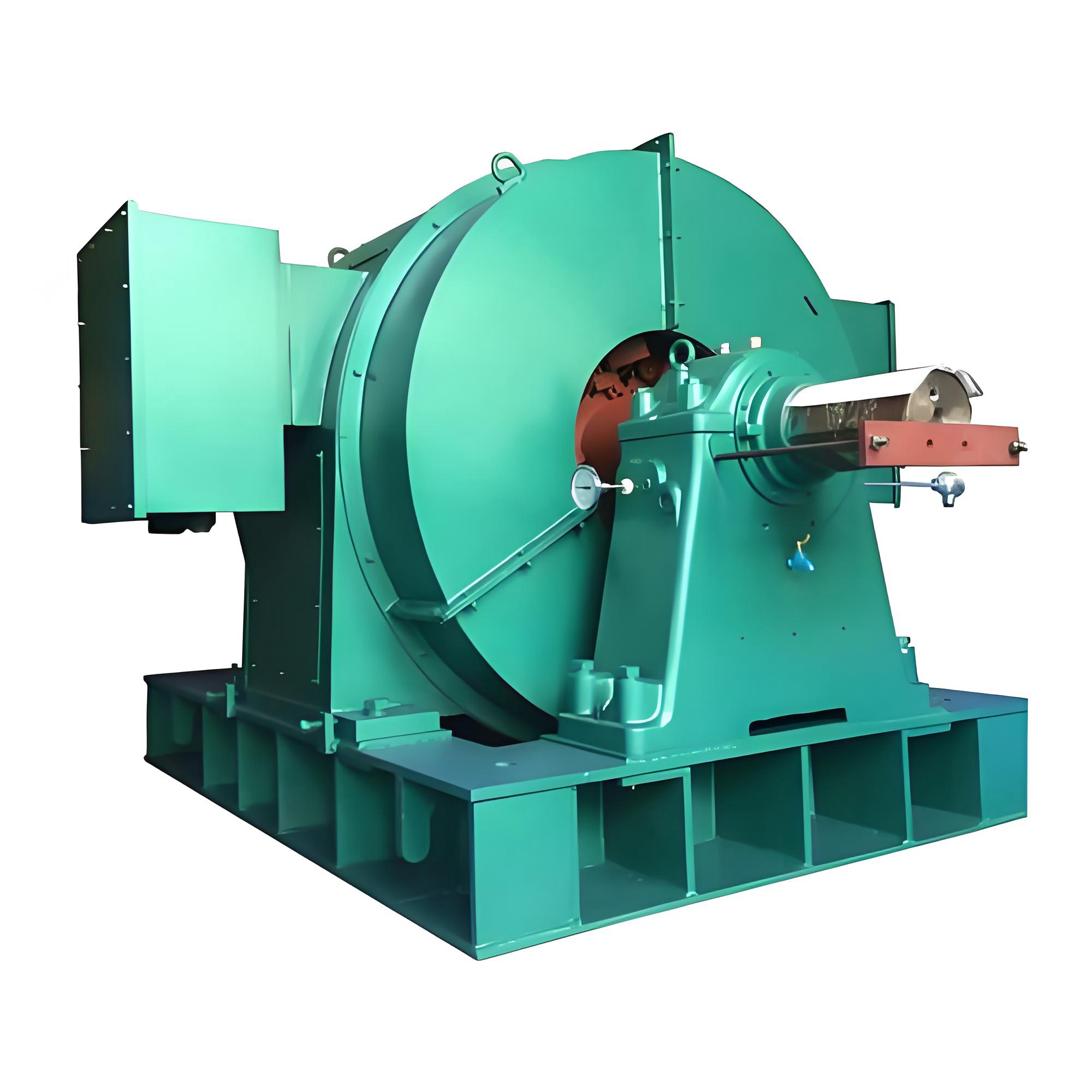

Simo ZTP Railway Motor: A reliable power source for locomotive operation

Designed for railroad locomotivesCore power equipmentSimo ZTP series motors are characterized by theirExcellent stability and environmental adaptability, which became the auxiliary system for internal combustion locomotives and electric locomotivesKey components。

Simo ZTP Railway MotorIt is designed for railroad locomotivesDC Auxiliary MotorWidely used inInternal combustion and electric locomotivesof the auxiliary system. This series of motors is strictly in accordance with theOXD.515.010-2001General Technical Conditions for DC Auxiliary Motors for Railway Locomotives and Moving Vehicles is designed and manufactured to be able to be used inExtreme environmental conditionsStable operation under to provide locomotives withReliable power support。

act asSimo motorsSpecialized in the railroad sector, the ZTP series of motors incorporates theAdvanced motor design与Rigorous manufacturing processpossessRobust structure, high efficiency, stable operation, easy maintenanceand other technical features, becoming the locomotive auxiliary system of thecore power unit (CPU)。

I. Product overview and technical characteristics

1. Product profile

Simo ZTP railroad motors are specially designed forRailroad locomotive working conditionsDesigned DC auxiliary motor series. This series of motor adoptsModular design conceptThe power of the auxiliary equipment can be configured flexibly to meet the needs of different locomotives.。

These motors are specifically designed to drive internal combustion locomotives and electric locomotives on theHydraulic pumps, blowers, air compressors, auxiliary generators, speed generators and other auxiliary machineryThey are the core power source of locomotive auxiliary system. They are the core power source of the locomotive auxiliary system to ensure the normal operation of each auxiliary system of the locomotive and guarantee the safe and stable operation of the locomotive.

2. Description of models

Simo ZTP railroad motors adopt uniform naming rules, taking "ZTP-62K" as an example:

- "Z.":: IndicatesDC motor

- "T": Indicates rail transportation

- "P": Indicates a specialized package

- "62": Indicates the seat number

- "K": Indicates distinguishing codes

Also.ZBTModels indicate DC enclosed railroad supporting motors, to meet the needs of different installation environments。

3. Core technical characteristics

Simo's ZTP railroad motors have a number of outstanding technical features:

- Strong environmental adaptability: The motor can withstand the normal operation of the locomotive whenShock and vibrationand maintain normal operation during rain, snow, wind, and sand attacks

- Wide temperature range capability: Suitable for use in ambient temperatures of-40℃~+45℃Some models can even be adapted to-45℃~+50℃extreme environments

- High Altitude Suitability: For altitudeNot exceeding 1200mThe special provisions of the visible technical conditions for areas exceeding 1200m to 4000m.

- Excellent protection: Protection class up toIP23and above, effectively preventing dust, moisture and other contaminants from entering the inside of the motor

Technical parameters and performance indicators

Simo ZTP railroad special motors cover a wide range of technical specifications to meet the power needs of different locomotive auxiliary equipment. The following are the main technical parameters of this series of motors:

| parameter category | Technical specifications and performance indicators |

|---|---|

| rating | 0.4kW~160kW (depending on model) |

| rated voltage | 48V, 75V, 78.5V, 96V, 110V, 115V, 220V (depending on model) |

| rated speed | 900r/min~3300r/min (depending on model) |

| Excitation method | Parallel excitation, other excitation, series excitation, re-excitation (depending on the model) |

| Rated efficiency | 68% to 85.9% (depending on model) |

| work system | S1 (continuous duty) |

| Insulation class | F |

| protection class | IP23, IP44 (customizable on request) |

| Cooling method | IC01 (self-cooling) |

| Installation | IMB3, IMB35, IMB10, IMV10 (depending on model) |

Typical model performance parameters

The following are detailed performance parameters for some typical models in the ZTP series:

| model number | Rated power (kW) | Rated voltage (V) | Rated speed (r/min) | Excitation method | Efficiency (%) | main application |

|---|---|---|---|---|---|---|

| ZTP-11 | 0.4 | 110 | 1500 | spur sb on | 68 | Internal combustion locomotives, fuel pump motors |

| ZTP-12 | 0.6 | 110 | 1500 | And encouragement/other encouragement | 71 | Internal combustion locomotives, fuel pump motors |

| ZTP-22 | 2.2 | 110 | 3000 | spur sb on | 81 | General purpose auxiliary machinery |

| ZTP-62G | 13 | 110 | 1500 | spur sb on | 85 | Internal combustion locomotives, air-machine motors |

| ZTP-61L | 11 | 220 | 2000 | impel | 85.9 | Electric locomotives, ventilator motors |

III. Structural design and configuration

1. Motor body structure

Simo ZTP railroad motor adoptsRugged structural designEach component is carefully designed and optimized:

- Stand design: AdoptionQuality materialsManufactured with sufficient strength and rigidity to withstand vibration and shock during locomotive operation.

- magnetic pole configuration: Magnetic poles are usedStamped from high quality steel plateThe magnetic field is mounted on the rotor yoke together with the pole coils to ensure a stable magnetic field output.

- Armature design: The armature core is made ofHigh quality silicon steel sheet stackingReduces eddy current losses and improves motor efficiency.

2. Diversified mounting configurations

In order to adapt to the needs of different locomotive mounting space, ZTP series motors provide a variety of mounting structures.:

- IMB3: Horizontal, stand with feet for standard installation environments

- IMB35: Horizontal, base with feet and flange on end caps for more flexible mounting options

- IMB10Horizontal, no feet, flange on the base for space-constrained environments.

- IMV10Vertical, footless, shaft extended downward, flange on base for special mounting needs.

3. Flexible outlet box configuration

ZTP series motors offer flexible outlet box configuration options:

- Standard outlet box location: On the left side of the seat (for the positive box) when viewed from the drive end

- Possible to select the location of the cable box: Can be set on the right side of the base (for reverse box) or on the top of the base according to the user's needs

- Special models without outlet box: No outlet box for motors of IMB10, IMV10 mounting type to meet special wiring requirements.

IV. Application areas and scenarios

Simo ZTP motors for railroads play a key role in railroad transportation thanks to their reliable performance and robust construction:

1. Equipment for major applications

ZTP series motors are mainly applied to the following locomotive auxiliary equipment:

- hydraulic system: drives the hydraulic pumps that power the locomotive's hydraulic system

- ventilation system: Drive blowers and ventilators to ensure ventilation and heat dissipation inside the locomotive

- air braking system: Drive air compressors to provide air for the locomotive's braking system

- Generation system: Drive auxiliary generators to provide power to locomotive auxiliary circuits

- tachymeter system: Drives a speed generator to provide speed feedback to the locomotive control system

2. Applicable locomotive types

ZTP series motors are widely used in the following locomotive types:

- automobile: Powering all types of auxiliary equipment for internal combustion locomotives

- electric locomotive: Meeting the power needs of electric locomotive auxiliary systems

- locomotive: Reliable powering of auxiliary systems for moving trains

V. Product Advantages and Values

1. High reliability design

Simo's ZTP railroad motors offer significant advantages in terms of reliability:

- Rugged structural design: AdoptionOptimized mechanical structurecan withstand the locomotive's operatingShock and vibrationEnsure long-term stable operation

- High-quality materials: The key components are adoptedQuality materialsManufacturing, wear and corrosion resistance, extended service life

- Strict quality control: Quality control from raw materials to finished products to ensure that each motor meets the standard requirements.

2. Ease of maintenance

This series of motors has been designed with ease of maintenance in mind:

- modular design: Modularized design of key components to reduce maintenance difficulties and spare parts inventory

- Easily accessible structureRational structural design makes routine inspection, maintenance and overhaul work more convenient.

- Perfect after-sales service system: Provide rapid response technical services to ensure timely troubleshooting

3. Energy-efficient features

ZTP series motors have excellent energy saving effect:

- Highly efficient electromagnetic design: ByOptimized electromagnetic solutionsReduces iron and copper losses and improves operating efficiency.

- Proper power matchingVarious power levels are available to avoid the waste of energy of "big horse pulling small car".

VI. Installation and use guide

1. Installation environmental requirements

Simo ZTP railroad motors have clear requirements for the installation environment:

- environmental conditions: Suitable for use at altitudeNot exceeding 1200mAmbient temperature-40℃~+45℃working environment

- Specialized environmental adaptation: For environments with an altitude of more than 1200m to 4000m above sea level, refer to the special provisions of the technical conditions.

- protective measure: In the rain, snow, wind, sand attack environment, the motor has a special protection design to ensure normal operation.

2. Electrical connections and configuration

Correct electrical connections are a prerequisite for reliable motor operation:

- Power Access: Connect to the power supply according to the rated voltage and current indicated on the nameplate of the motor to avoid over-voltage or under-voltage operation.

- grounding: Ensure that the motor is reliably grounded to prevent electrical faults from harming equipment and personnel

- Protection Configuration: Appropriate protection devices should be configured according to the motor capacity and system requirements, including overcurrent, overload and other protection.

VII. Services and technical support

1. Quality assurance systems

Simo Motor has established a perfect quality assurance system to ensure the excellent quality of ZTP railroad special motors:

- International Standard Certification: ByISO9001 Quality System Certification、ISO14000 Environmental Management System和OHSAS18000 Occupational Health and Safety Management Systemaccreditation

- Strict testing process: In the manufacturing process afterMultiple rigorous testsEnsure that the performance of the product meets the requirements of the standard

- Comprehensive performance testing: Each motor isRigorous factory testingIncludes no-load test, load test, etc.

2. After-sales service commitments

Simo motors provide customers with comprehensive after-sales service guarantee:

- rapid response: Customers who find quality problems in the course of use, upon notification of the24-hour responseIf on-site service is requiredActivated within 48 hours

- Professional Support: Maintenance personnel will not be withdrawn until the fault is eliminated to ensure that the equipment is returned to normal operation

- Lifetime Service: Once a Simo motor product is soldLifetime Cost WarrantyProvide long-term technical support to customers

3. Notes on ordering

When ordering ZTP railroad special motors, please note the following matters:

- Clarification of technical parametersPlease specify the motor model, power, voltage, speed, working system, structure and installation type, excitation mode and other details when ordering.

- Statement of special needsIf there are special requirements, please put forward the specific requirements in advance, and sign a contract or technical agreement after both parties have negotiated and agreed.

- Export PrecautionsIf you need to go abroad, please specify in the contract when there is a requirement for a hot and humid belt.

Simo's ZTP railroad motors are characterized by theirExcellent technical performance、Rugged structural design和Reliable operational performance, has become the railroad locomotive auxiliary systemPreferred Power Solutions. Simo motors are available throughContinuous technological innovation和Strict quality controlTo ensure that every ZTP railroad-specific motor isHarsh railroad environmentsubscribeStable and efficientThe power of the support.

Choosing Simo ZTP railroad motors is to choose theReliable equipment performance和Complete technical servicesWe are looking forward to cooperating with you to promote the technical progress and development of China's railway industry. We are looking forward to cooperating with you to jointly promote the technological progress and development of China's railroad industry.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206