A Comprehensive Analysis of the Working Principles and Core Advantages of High-Efficiency Energy-Saving Variable-Frequency Motors

Date: 2025-12-11 Categories: Company News Views: 9624

Excerpt:

Unveiling Variable Frequency Motors: Why They Are Key to Industrial Energy Efficiency Transformation In today's industrial landscape driven by dual carbon goals and relentless pursuit of efficiency, business owners and engineers face a common challenge: how to drastically reduce costly electricity bills without compromising production power? Traditional fixed-speed drives often result in massive energy waste—akin to driving a car while simultaneously pressing the accelerator and brake. The advent of variable frequency motors precisely addresses this issue.

Article Catalog[Hidden]

Unveiling the MysteryVariable Frequency MotorWhy is it crucial for industrial energy efficiency transformation?

In today's industrial environment, where pursuing “dual carbon” goals and maximizing efficiency are paramount, business owners and engineers face a common challenge: how to significantly reduce costly electricity bills without compromising production power? Traditional fixed-speed drive methods often result in massive energy waste—much like driving a car while simultaneously pressing the accelerator and brake pedals.Variable Frequency MotorIts emergence addresses this very challenge, earning it the title of the “energy-saving heart” of modern industrial automation. It is quietly spearheading a revolution in power and efficiency.

Not simply a “motor plus inverter”

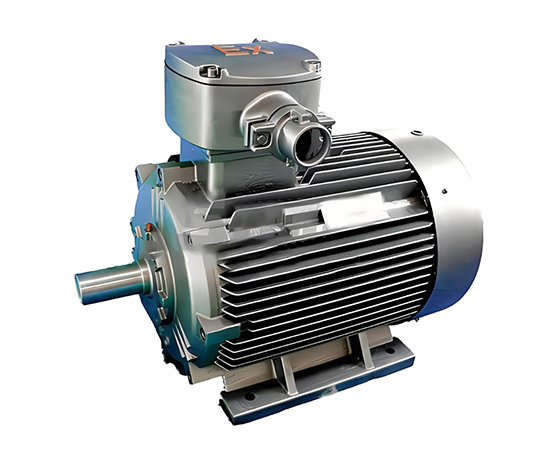

Many people have a misconception that simply connecting a standard motor to a variable frequency drive (VFD) is sufficient.Variable Frequency MotorActually, that's not the case. While standard motors can operate at low frequencies, prolonged low-speed operation can lead to poor heat dissipation, insulation aging, and even burnout. The realVariable Frequency Motor(Variable Frequency Motor) was designed from the outset to fully accommodate the unique operating conditions of variable frequency speed control.

The core difference lies in the cooling system and insulation strength. In conventional motors, the cooling fan is connected to the rotor shaft, resulting in low airflow at slow rotational speeds; whereasVariable Frequency MotorTypically equipped withStand-alone Powerful Cooling FanRegardless of how the motor speed changes, the cooling effect remains constant. Additionally, to address the high-frequency pulse voltage generated by the inverter, the variable-frequency motor employsReinforced Insulation StructureEnsures long-term stability under frequent gear changes and high-frequency voltage surges.

Precision Speed Control Delivers a Leap in Energy Efficiency

Variable Frequency MotorThe greatest advantage lies in its outstanding energy-saving performance, particularly evident in applications involving fans and pumps. Traditional flow control relies on valve regulation, where motors constantly run at full speed—not only wasting energy but also increasing mechanical wear.

Through integration with variable frequency control systems,Variable Frequency MotorIt enables stepless speed regulation, delivering precise power output according to actual operational requirements. This *“on-demand power allocation”* mode effectively eliminates the phenomenon of “overkill.” Data indicates that in typical fluid transmission systems, the use of variable frequency speed control technology often achievesEnergy savings rate from 20% to 50%significantly reduced the company's operating costs.

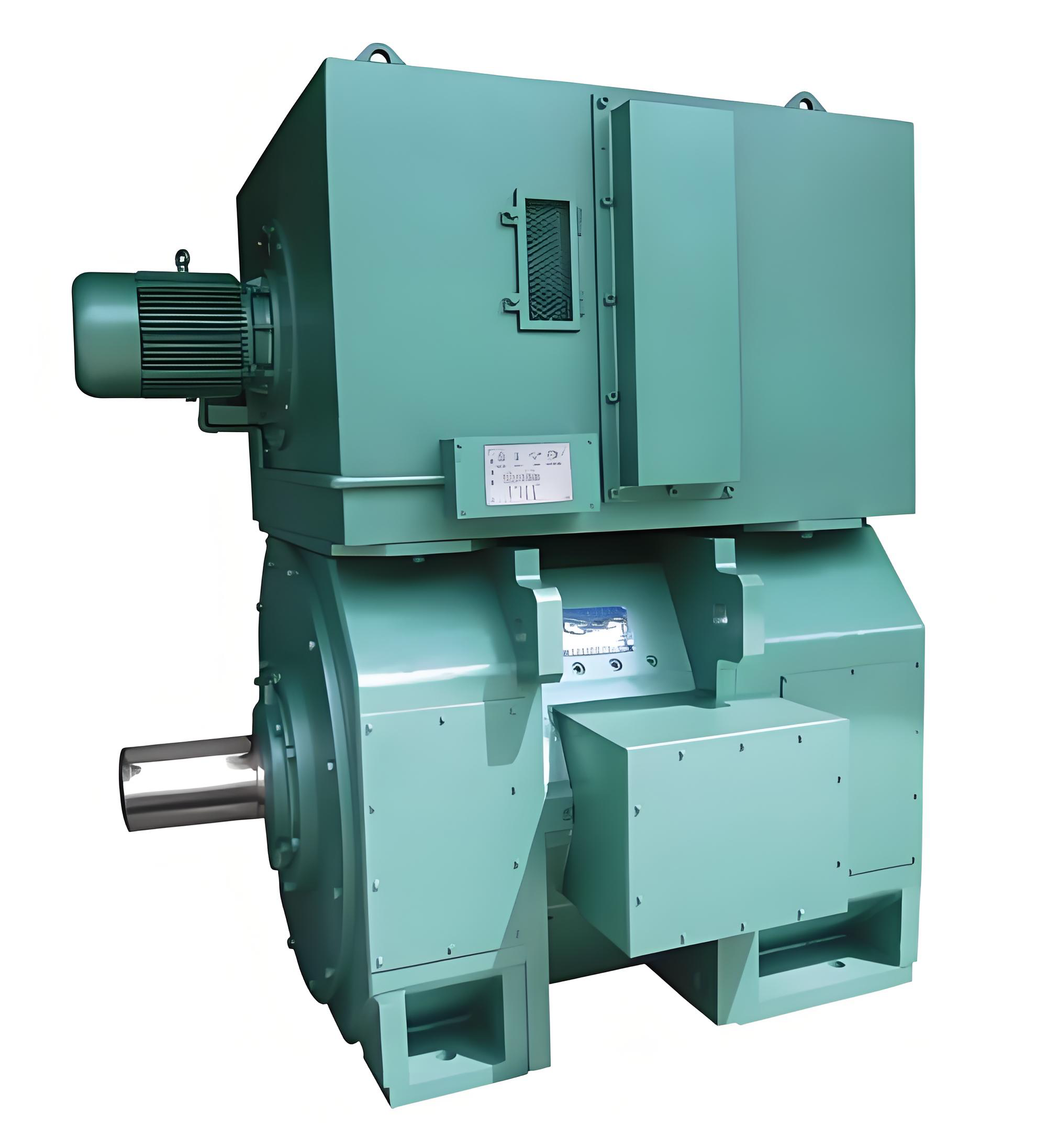

Case Study: Retrofit of a Chemical Plant's Pump System

To better grasp its value, let's examine a real-world example. A large chemical plant's circulating water system operates 24/7 year-round. Previously, it relied on several standard three-phase asynchronous motors, with water pressure controlled by adjusting valve openings. Due to significant fluctuations in production load, valves frequently remained partially open, resulting in extremely high energy losses.

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2023/08/1763957873-21734.jpg)

During the technological upgrade, the factory introduced specializedVariable Frequency MotorReplace the original power source. After retrofitting, the system automatically adjusts motor speed based on pipeline pressure: the motor operates at low speed during low load and smoothly accelerates during high load. Data monitoring after three months of operation shows that the system's overall power consumption has decreased by35%Moreover, due to the smooth startup, the water hammer effect is eliminated, and the frequency of pipeline maintenance is significantly reduced.

The “All-Rounder” for Demanding Conditions”

In addition to energy efficiency,Variable Frequency MotorIn terms of automation control precision, they also play an irreplaceable role. In CNC machine tools, textile machinery, and paper production lines, processes often require motors to have a wide speed regulation range and rapid dynamic response capabilities. High-quality variable-frequency motors can maintainConstant Torque OutputMaintaining constant power output at high frequencies ensures the continuity of the production process and the stability of product quality.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206