Xi'an Xima Variable Frequency Motor Manufacturer Direct Sales: High Efficiency, Energy Saving, Precise Speed Control

Date: 2025-12-09 Categories: Company News Views: 4986

Excerpt:

In-Depth Analysis of Xima Variable Frequency Motors: The Core Power Driving Industrial Energy Efficiency and Precision Control Against the backdrop of concurrent “Industry 4.0” and “dual carbon” goals, the manufacturing sector's demands for power systems have long transcended mere “drive” functionality, advancing toward high energy efficiency, precision control, and system stability. As the industrial heart, the technological evolution of electric motors directly impacts production line

Article Catalog[Hidden]

In-Depth AnalysisXima Variable Frequency Drive MotorThe Core Power Driving Industrial Energy Efficiency and Precision Control

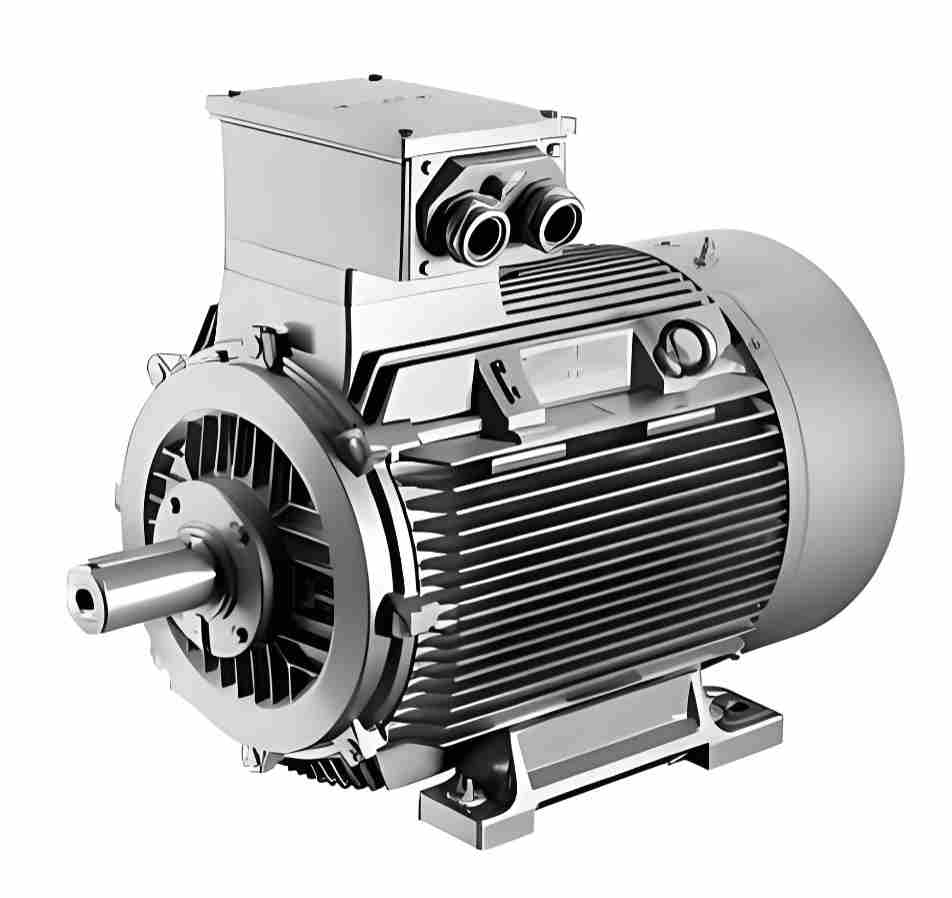

Against the current macro backdrop of concurrent “Industry 4.0” and “dual carbon” goals, the manufacturing sector's demands on power systems have long transcended mere “drive” functionality, shifting instead towardHigh energy efficiency, precise control, and system stabilityAdvancing. As the industrial heart, the electric motor's technological evolution directly impacts the overall efficiency of production lines. Among numerous brands,Xima Variable Frequency Drive MotorWith its deep technical expertise and outstanding field performance, it has become the preferred solution for automation upgrades and equipment modernization in numerous large industrial and mining enterprises. This article will delve into why this motor has captured market attention and how it delivers tangible cost savings and efficiency gains for businesses.

Electromagnetic Solution Specifically Designed for Variable Frequency Speed Control

When operating on non-mains frequency power sources, conventional motors often face risks such as efficiency degradation, excessive temperature rise, or even insulation breakdown.Xima Variable Frequency Drive MotorThe core advantage lies in itsDedicated electromagnetic designThe R&D team optimized the stator and rotor slot shapes to address the harmonic characteristics of inverter-supplied power, effectively suppressing losses caused by higher-order harmonics.

This design not only enables the motor to maintain its performance during low-frequency output,Constant Torque Characteristicscan maintain even during high-frequency operationConstant power outputThis achieves an extremely wide speed regulation range. Whether it's the ultra-low-speed, smooth tension control required in papermaking machinery or the high-speed cutting scenarios of CNC machine tools, it delivers precise power response, completely eliminating the “incompatibility” issues traditional motors face under variable-frequency operating conditions.

Unique cooling structure and insulation system

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2023/08/1763950601-ztp2.png)

A major challenge with variable frequency speed control lies in heat dissipation during low-speed operation. Traditional motors rely on main shaft fans for cooling; however, as rotational speed decreases, airflow diminishes, making the motor highly susceptible to overheating and burnout.Xima Variable Frequency Drive Motorskillfully employedIndependent Axial Flow FanForced ventilation cooling is employed. This ensures that the airflow volume of the cooling system remains constant regardless of motor speed variations, guaranteeing thermal stability during prolonged low-speed, heavy-load operation.

Additionally, to address the high-frequency pulse voltage surges generated by the frequency converter,Simo motorsEnhanced measures have been implemented in the insulation system. By utilizing corona-resistant enameled wire and a specialized vacuum pressure impregnation (VPI) process, the electrical and mechanical strength of the windings has been significantly improved, substantially extending the motor's service life.

Case Study: The Energy-Saving Transformation of Fan-Pump Systems

Taking the renovation of a large chemical plant's circulating water system as an example, the facility previously relied on traditional motors with valve-regulated flow control, resulting in significant energy waste. Upon introducingXima Variable Frequency Drive MotorWhen integrated with the variable frequency control cabinet, closed-loop control is achieved.

The system automatically adjusts motor speed based on actual water pressure requirements. When nighttime water usage decreases, the motor speed automatically reduces. Data shows that the upgraded system achieves an energy savings rate of28% and aboveMore importantly, the implementation of soft start eliminates the impact of high currents on the power grid while reducing mechanical wear, nearly doubling the equipment's maintenance cycle. This case vividly demonstrates the high performance.Variable Frequency Motor在Energy Conservation and Consumption Reductionenormous potential in this area.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206