High-Efficiency Energy-Saving YKK Series 10kV High-Voltage Three-Phase Asynchronous Motor

Date: 2025-12-10 Categories: Company News Views: 2491

Excerpt:

In the realm of heavy industry, the “heart” of equipment often determines the efficiency and stability of the entire production line. As modern industrial demands for single-unit power continue to rise, traditional low-voltage motors frequently struggle with high-power drive tasks due to excessive current and line losses. At this juncture, 10kV high-voltage motors emerge as the solution, offering superior energy efficiency and robust power output.

In the realm of heavy industry, the “heart” of equipment often determines the efficiency and stability of the entire production line. As modern industrial demands for single-unit power continue to rise, traditional low-voltage motors frequently struggle when tasked with high-power drives, often failing due to excessive current and high line losses. At this point,10kV high-voltage motorWith its outstanding energy efficiency ratio and robust power output, it has become the driving force in mining, petrochemical, power generation, and water conservancy projects, earning the reputation as the “pillar” of industrial automation.

Why choose the 10kV voltage level?

Compared to common 380V or 6kV motors,10kV high-voltage motorThe core advantage lies in itsHigh voltage, low currentCharacteristics. According to the physics formula P=UI, at the same output power, the higher the voltage, the lower the current. This characteristic yields two direct economic benefits:

- Reduce line lossesThe reduction in current directly results in a geometric decrease in line heat loss (I²R), meaning enterprises can save substantial electricity costs during long-term operation.

- Reduce infrastructure costsDue to the lower current, the cross-sectional area of the accompanying cables can be significantly reduced, thereby lowering the consumption of non-ferrous metals and the initial investment in power distribution facilities.

Core Application Scenarios and Technical Features

10kV high-voltage motorTypically applied to large-scale machinery and equipment with power ratings ranging from 200 kW to several thousand kilowatts. For instance, in large thermal power plants, they drive fans and coal mills; in steel mills, they power rolling mills; or in municipal engineering projects, they serve as the power source for large water pumps.

Its design and manufacturing processes are exceptionally meticulous. To withstand high-voltage surges of 10kV, the stator windings typically employ F-class or H-class insulation materials, treated through *vacuum pressure impregnation (VPI)*. This process not only eliminates air gaps within the insulation layer but also effectively prevents corona discharge, significantly extending the motor's service life and enabling it to withstand harsh industrial environments such as damp and dusty conditions.

Case Study: Energy Efficiency Upgrade at a Chemical Plant

To better grasp its value, we can examine a compressor unit retrofit case study from a major chemical enterprise. The company originally operated multiple outdated low-voltage, high-power motors, which not only suffered from high failure rates but also delivered significant grid impact during startup, frequently causing voltage fluctuations across the plant.

During the technological upgrade, the engineering team introducedYKK Series 10kV High-Voltage MotorsReplace existing equipment. The renovation results show:

- Startup Performance OptimizationThrough the high-voltage soft-start device, the motor's starting current is limited to within 2-3 times the rated current, completely resolving grid fluctuation issues.

- Significant energy savingsThanks to the high efficiency of high-voltage transmission, the overall system operational efficiency has improved by approximately 4.51%. Calculations indicate that with an annual operation of 8,000 hours, the energy cost savings alone will recoup the equipment retrofit investment within two years.

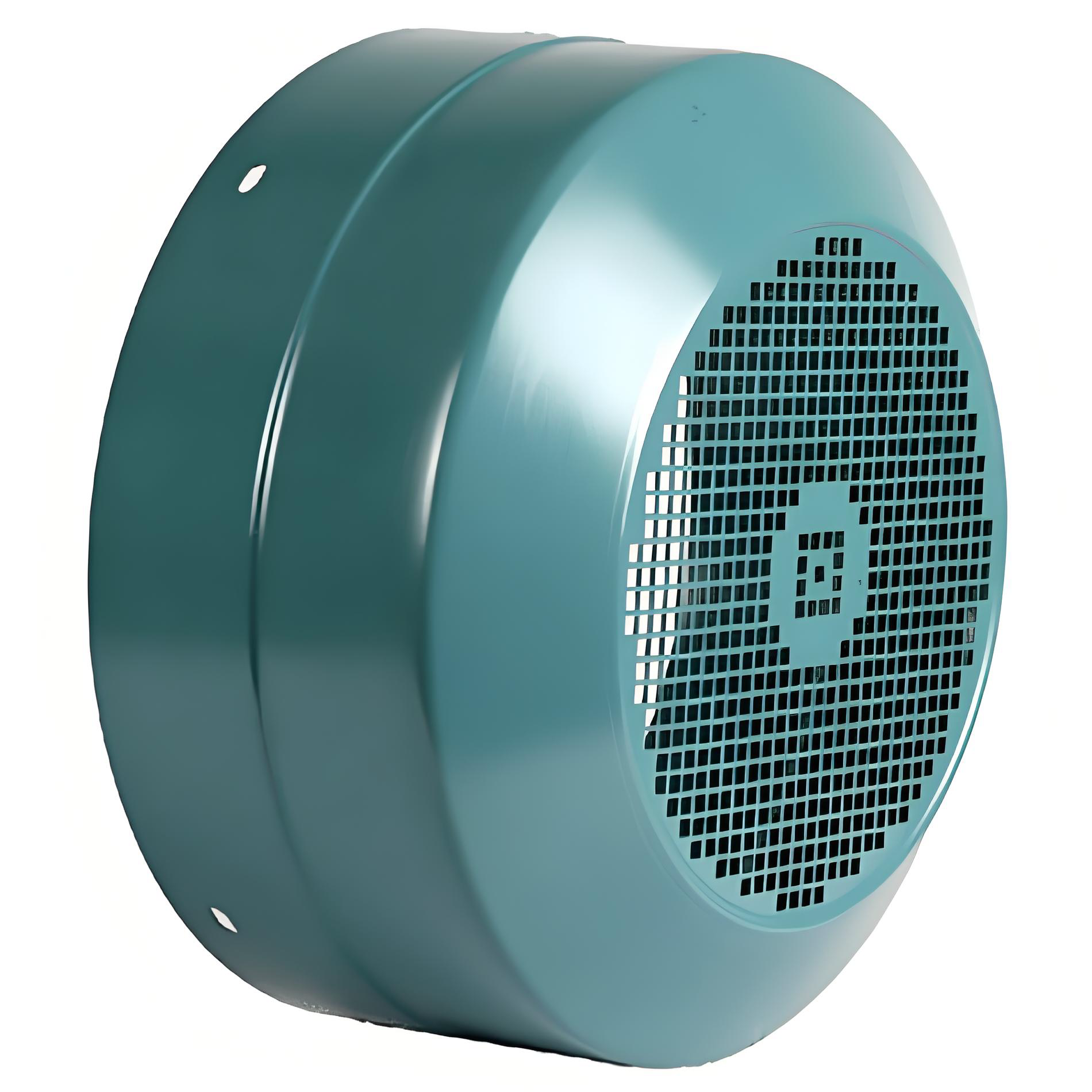

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2023/08/1764154936-3839.jpg)

Key Recommendations for Selection and Maintenance

Although10kV high-voltage motorHigh performance, but precise selection is essential. When procuring motors, enterprises should not only focus on rated power and rotational speed but also pay close attention to the motor'sprotection class(such as IP54 or IP55) andCooling method(e.g., IC611 air-to-air cooling or IC81W air-to-water cooling). For instance, in dusty environments such as cement plants, enclosed structures must be selected to prevent dust from entering the motor and damaging the insulation.

Additionally, during routine maintenance,Monitoring of Insulation ResistanceThis is of paramount importance. Due to the extremely high operating voltage, even the slightest insulation degradation can lead to breakdown incidents. Therefore, establishing a regular insulation testing and bearing temperature rise monitoring mechanism is essential to ensure10kV high-voltage motorEssential means for long-term stable operation.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206