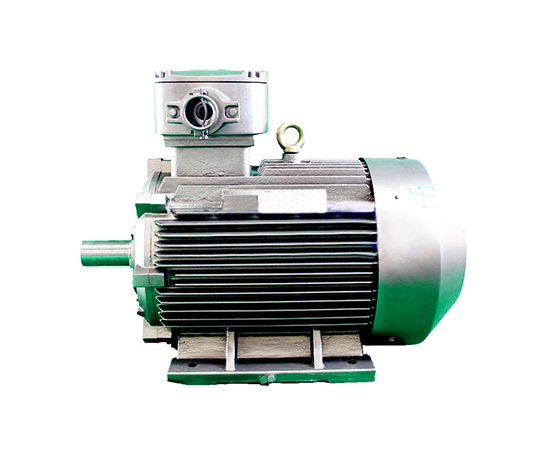

Xi'an Xima Motor Genuine Parts Wholesale Manufacturer Direct Sales with Complete Model Range

Date: 2025-12-12 Categories: Company News Views: 8531

Excerpt:

Core Power Demands No Compromise: Extending Equipment Lifecycles with Genuine Cima Motor Parts In the fast-paced world of modern industrial production, motors serve not only as the “heart” of equipment but also as the cornerstone of stable production line operation. Yet many enterprises overlook a seemingly minor yet critical detail in equipment maintenance—the compatibility of replacement parts. Once a motor fails due to substandard components,

Core Power: No Compromise Allowed How to Achieve It Through Genuine ProductsSimo motorsExtend equipment lifecycle with replacement parts

In the fast-paced world of modern industrial production, electric motors are not only the “heart” of equipment but also the cornerstone of stable production line operation. However, many enterprises often overlook a small yet critical detail in equipment maintenance—Compatibility of accessoriesOnce a motor fails due to substandard parts, the resulting downtime losses can often be hundreds or even thousands of times the cost of the components themselves. For Xima motors, widely used across major heavy industrial sectors, selecting the correctSimo Motor PartsIt is by no means a simple replacement task, but rather a battle to safeguard efficiency and safety.

Precision Matching: The Importance of Original Manufacturer DNA

Motor design is a meticulous systems engineering endeavor, where every screw torque and bearing clearance is rigorously calculated. While aftermarket parts commonly available on the market may appear dimensionally compatible, they often fail to meet the required standards in material density, thermal expansion coefficient, and electrical conductivity.Simo Motor PartsOriginal factory standards.

The most common consequence of using non-genuine parts is “hidden wear.” For example, using carbon brushes with mismatched hardness not only accelerates slip ring wear but may also generate sparks due to poor contact, potentially burning out the motor windings. Only by consistently using genuine parts can the electromagnetic and mechanical balance within the motor be preserved, thereby maintaining the equipment's efficient operation.

Key Component Analysis: Success or Failure Lies in the Details

In the full lifecycle management of electric motors, there are several categories.Simo Motor PartsThe replacement frequency is relatively high, making it a key focus for procurement personnel:

- Bearing SystemAs the core component supporting rotation, genuine bearings utilize specialized steel and lubricating grease to withstand the temperature rise and vibration generated during high-load operation of Xima motors.

- Carbon brushes andbrush holderRegardingDC motorFor wound-rotor motors, high-quality carbon brushes ensure excellent commutation performance.Poor-quality carbon brushes are often the culprit behind motor sparking.

- cooling fanHeat dissipation efficiency directly determines the insulation lifespan of the motor. The original fan blades feature fluid dynamics-optimized angles, delivering maximum airflow while minimizing noise.

Case Study: A Cement Plant's Cost-Cutting Lesson

To better understand the importance of selecting the right accessories, we can refer to a real-life case from a large cement plant in Shaanxi. One of the plant's large ball mills was equipped with a Xima ZR series DC motor. During an annual maintenance check, the procurement department, aiming to control costs, purchased a batch of non-original brush holders and carbon brushes.

Initial operation showed no abnormalities, but just two months later, the motor began exhibiting excessive heat and severe vibration.Upon disassembly, engineers discovered that uneven spring pressure from the non-genuine brush holder caused severe burn-through at the carbon brush-commutator contact points, even damaging the commutator surface. Ultimately, the factory was forced to halt production for three days for emergency repairs and incurred costs five times higher than the original budget to replace the entire collector assembly and precision-machine the commutator. After reinstalling genuine parts,Simo Motor PartsSince then, the equipment has operated continuously without any recurrence of similar malfunctions.

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2023/08/1763941161-0032-scaled.png)

How to Mitigate Procurement Risks

Faced with a market flooded with mixed-quality suppliers, businesses must remain vigilant during procurement. GenuineSimo Motor PartsAuthentic products typically feature distinct anti-counterfeiting markings and standardized packaging. Users are advised to purchase exclusively through official authorized channels or certified distributors, avoiding the temptation of minor savings that could lead to significant safety risks. Additionally, establishing a comprehensive inventory management system for spare parts and conducting regular inspections of storage environments are crucial to preventing corrosion of metal components or moisture damage to insulating parts, thereby ensuring the performance of spare components.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206