Article Catalog[Hidden]

- TYC Series High-Efficiency High-Voltage Permanent Magnet Synchronous Motors: Pioneering the Industrial Power Efficiency Revolution

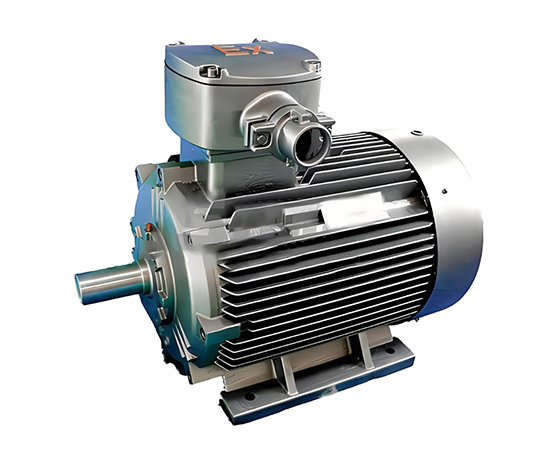

TYC Series High-Efficiency High-Voltage Permanent Magnet Synchronous Motors: Pioneering the Industrial Power Efficiency Revolution

In the industrial power sector, the TYC series of high-efficiency, high-voltage permanent magnet synchronous motors is making its mark withExcellent energy efficiency performance和Reliable operating characteristicsIt has become the preferred solution for energy-saving retrofits and power upgrades in various industries.

TYC Series High Efficiency High Voltage Permanent Magnet Synchronous Motor是Simo motorsYears of experience in designing and manufacturingEnergy efficient power equipmentAdoptionAdvanced permanent magnet technology and precise manufacturing processpossessHigh efficiency, high power factor, compact size, lightweight, low temperature rise, and significant energy-saving effects.Distinctive featuresThis series of motors strictly adheres toJB/T 12682-2016Technical Specifications for TYC Series (IP23) High-Efficiency High-Voltage Permanent Magnet Synchronous Motorsprovides reliable high-voltage permanent magnet synchronous motor solutions for industrial users.

I. Product overview and technical characteristics

1. Product profile

The TYC series high-efficiency high-voltage permanent magnet synchronous motors are designed by Simo Motors forModern industry demands both energy consumption and reliabilityThe newly developed high-voltage electric motor. This series of motors adoptsPermanent Magnet Direct Drive TechnologyCompared with traditional asynchronous motors, it possesses distinct technological advantages.。

As a revolutionary alternative to the traditional "asynchronous motor + gear reducer" drive configuration, the TYC seriesDirectly drive the loadBy eliminating the gear reducer and removing all intermediate transmission components, the system reliability is enhanced, the transmission chain is shortened, efficiency is improved, and failure rates are reduced.。

2. Core technical characteristics

The TYC series of high-efficiency permanent magnet synchronous motors integrates multiple innovative technologies, offering significant performance advantages:

- Excellent energy efficiency featuresHigh motor efficiency and high power factor significantly improve the power quality of the grid, fully utilize the capacity of the existing grid, and reduce grid investment.

- Excellent runtime performance: Has the followingHigh transmission efficiency, excellent starting torque performance, energy-saving, low noise, minimal vibration, low temperature rise, safe and reliable operation, low installation and maintenance costs.and other advantages

- Wide voltage adaptability:According to user requirements, we can provideMultiple voltage levelsproducts

Technical parameters and performance indicators

The TYC series of high-efficiency permanent magnet synchronous motors covers a wide range of technical specifications to meet the power requirements of diverse industrial applications:

Main technical parameters

Description of performance characteristics

TYC Series Motors inElectromagnetic design, structural strength and thermal performanceAll aspects have been fully optimized:

- Broad economic operating range:in25% to 120% Rated Load RangeBoth can maintain high efficiency and power factor.

- high power factor:No electrical excitation required, power factor canApproximately 1

- Synchronous Speed StabilizationLoad Torque VariationDoes not affect rotational speedThe rotational speed is maintained at synchronous speed.

III. Structural design and configuration

1. Motor body structure

The TYC series high-efficiency high-voltage permanent magnet synchronous motors adoptInnovative Design PhilosophyEach component is carefully designed and optimized:

- Permanent magnet rotor designThe air gap magnetic field is generated by the rotor-mountedRare Earth Permanent Magnet MaterialsfurnishPermanent magnet materials exhibit superior magnetic properties, enabling increased power density.

- Direct Drive StructurePermanent Magnet Synchronous MotorDirect-drive belt pulleyWith no intermediate transmission components, the system's reliability is enhanced.

- Compact design:You may chooseMore compact frame sizeHigh power density

2. Extended functionality configuration

The TYC series motors offer a wide range of expansion options to meet users' specific requirements:

- Multiple protection ratings: ProvidedIP23、IP54, IP55、IP56, IP67A variety of protection levels, such as to adapt to different working environments

- Variable Frequency Drive Compatibility: Designed to operate with variable frequency drives, featuringHigh starting torque, wide speed regulation rangeCharacteristics

- High efficiency cooling system:Utilizing advanced cooling technology to ensure the motor maintains optimal performance under various load conditions.Optimal temperature

IV. Application areas and scenarios

The TYC series of high-efficiency permanent magnet synchronous motors, renowned for their reliable performance and energy-saving characteristics, are widely applied across numerous industrial sectors:

1. Heavy industry

- Electric Power Industry: Applied toPower Plant Auxiliary Equipmentproviding stable power support

- Cement and Building Materials Industry: for drivingGrinding mill, blowerequipment capable of withstanding harsh operating conditions

- Mining and Metallurgical Industry: Specifically designed forCrusher, elevator, scraper conveyorHeavy equipment

2. General industrial areas

- Chemical Industry: Applicable toChemical Process Pumps, Compressorsand other equipment

- Port Terminal: forConveying equipment, lifting machinery等

- Washing and Sorting Industry: Applied toMining equipment, separation machinery等

3. Special application scenarios

The TYC series motors can also provide customized solutions tailored to specific environmental requirements:

- Fan and Pump Equipment:Particularly suitable for drivingFans, pumpsand other equipment

- Internal Mixer Equipment: forRubber and Plastics IndustryInternal mixing equipment

- Marine Propulsion System:can be used asMarine Propulsion Motorutilization

V. Product Advantages and Values

1. Energy efficiency benefits

The TYC series of high-efficiency, high-voltage permanent magnet synchronous motors offer significant economic benefits:

- Reduced operating costs: High-efficiency design can beSignificant reduction in energy consumptionThe overall power saving rate reached10-30%Reduced payback period

- Optimization of power factor: Permanent magnet synchronous motors havehigh power factorReduced investment in reactive power compensation equipment and improved grid quality

- Low life cycle costs: Although the initial investment is slightly higher, theEnergy saving benefits during operationDramatic reductions in total life cycle costs

2. Operational reliability

The TYC series motors offer distinct advantages in reliability:

- Rugged structural design: AdoptionOptimized mechanical structureThe product is designed to withstand mechanical and thermal stresses under a variety of operating conditions.

- Simplified Transmission System:Removed the gear reducerPermanent magnet synchronous motors directly drive the load, shortening the transmission chain, enhancing system reliability, and reducing failure rates.

- Strict quality controlFull-process quality control from raw materials to finished products ensures every motor meets specifications.JB/T 12682-2016Standard Requirements

3. Ease of maintenance

This series of motors has been designed with ease of maintenance in mind:

- Reduce maintenance stepsDirect Drive DesignEliminates gearbox maintenancethe procedures and fees

- modular design: Modularized design of key components to reduce maintenance difficulties and spare parts inventory

- Long life design: AdoptionClass F insulation systemLong design life, long maintenance intervals

VI. Installation and use guide

1. Installation environmental requirements

The TYC series of high-efficiency permanent magnet synchronous motors have specific requirements for the installation environment:

- environmental conditions: For use in conventional industrial environments

- Applicable placesWidely used inPower, Cement, Mining, Metallurgy, Washing and Sorting, Chemical Industry, Portacross various industries

- Specialized environmental adaptation: For special environmental conditions, customized designs can be provided to meet requirements

2. Installation and commissioning

Correct installation and commissioning is the key to ensure the normal operation of the motor:

- basic requirement: RequiredStrong and level foundationThe motor is designed to withstand the weight of the motor and the mechanical stresses of operation.

- alignment requirementsWhen electric motors and driven machinery are connected via direct drive, it must be ensured thatPrecise alignmentAvoidance of additional forces

- electrical connection: Follow the motor nameplate and wiring diagram for proper wiring to ensure thatreliable grounding

VII. Services and technical support

1. Quality assurance systems

Simo Electric has established a comprehensive quality assurance system to ensure the exceptional quality of its TYC series high-efficiency permanent magnet synchronous motors:

- standards compliance: The products strictly follow theJB/T 12682-2016industry standard

- Strict testing process: In the manufacturing process afterMultiple rigorous testsEnsure that the performance of the product meets the requirements of the standard

- Certification QualificationsThe TYC series of customized permanent magnet synchronous motors has been approved by the Ministry of Industry and Information Technology. "Energy Efficiency Star Energy-Saving Equipment Product Catalog

2. After-sales service commitments

Simo motors provide customers with comprehensive after-sales service guarantee:

- rapid responseUpon receiving an after-sales service request, the latestDispatch personnel to the customer's site within 48 hours.

- Professional SupportService Hotline:400-066-5888Provide clients with professional technical consulting services

- Ongoing services: Provide customers with long-term technical support and service guarantee

The TYC series high-efficiency high-voltage permanent magnet synchronous motors, with theirExcellent technical performance、Revolutionary Direct Drive Design和Reliable operational performanceIt has become the industrial powerhouse of thePreferred Solution. Simo motors are available throughContinuous technological innovation和Strict quality controlEnsure that every TYC series high-efficiency permanent magnet synchronous motor can operate atHarsh industrial environmentssubscribeStable and efficientThe power of the support.

Choosing the Simo TYC series high-efficiency permanent magnet synchronous motors means choosingReliable equipment performance和Complete technical servicesWe are looking forward to cooperating with you. We are looking forward to cooperating with you to jointly promote the progress and development of energy-saving technology in the industrial field.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206