Article Catalog[Hidden]

- TKK Series Synchronous Motors: The Efficient and Stable Core of Industrial Power

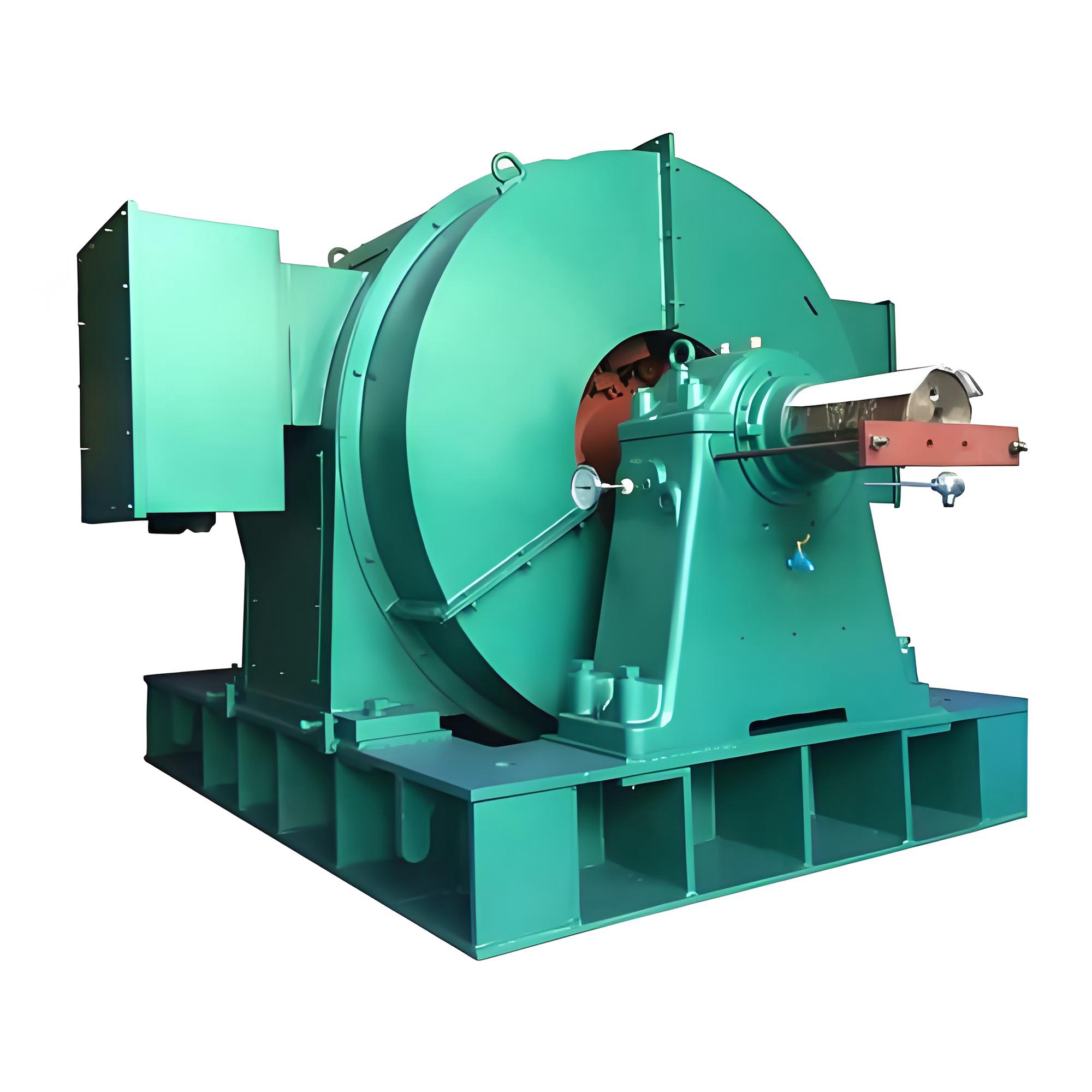

TKK Series Synchronous MotorHighly Efficient and Stable Industrial Power Core

In the industrial power sector, the TKK series synchronous motors are renowned for theirsuperior performance和Reliable stabilityis becoming the preferred prime mover equipment across numerous industries

TKK Series Synchronous Motor是Xi'an Simo Electric Machinery GroupThe large three-phase synchronous motors produced utilizeAdvanced motor design与Precision manufacturing processSpecifically designed for heavy-duty industrial applications. This series of motors achievesThyristor Excitation UnitAchieve efficient operation withRobust structure, high efficiency, stable operation, easy maintenanceand other technical characteristics, widely used inPetroleum, Chemical, PowerDrives equipment such as fans, pumps, and compressors in industries like...

I. Product overview and technical characteristics

1. Product profile

The TKK series synchronous motors areSimo motorsTargetingHeavy Industrial ApplicationsLarge-scale power equipment developed for environmental applications,Precision electromagnetic design与Optimized cooling systemEnsures stable operation in harsh environments. As the core power source in industrial applications, this series of motors strictly adheres toJB/T 8667.1-2011 Technical Specifications for Large Three-Phase Synchronous Motors Compliance with national standards ensures product reliability and compatibility.

The TKK series motors utilizeModular design conceptAllows flexible configuration based on different application requirements. The motor'sBox-type structure与Horizontal installationDesigned to adapt to a wide range of industrial environments, whileSliding BearingThe use of this ensures the reliability of the equipment under long-term continuous operation conditions.。

2. Description of models

The Simo Motor TKK series model numbers follow a unified naming convention. Taking "TKK1600-4/1430" as an example:

- "T": Represents synchronous motors

- "KK": Indicates air-to-air cooler

- "1600"Indicates the motor power is 1600 kW.

- "4"Indicates the number of poles in the motor

- "1430"The stator core has an outer diameter of 1430 mm.

This clear naming system enables customers to quickly identify the motor's fundamental parameters and characteristics, facilitating selection and matching.

3. Core technical characteristics

The TKK series synchronous motors incorporate multiple innovative technologies and offer significant performance advantages:

- Optimized cooling system: AdoptionAir-to-Air Cooler (KK) Effectively control the motor's operating temperature to ensure stable performance even in high-temperature environments.

- Robust insulation system: The stator winding is made ofClass F Insulation StructureTemperature rise shall be evaluated according to Class B standards, with sufficient provision made.Temperature Rise Margineffectively extend insulation lifespan

- Outstanding starting performance: Motor PermittedFull-voltage direct startIf the user's grid capacity is insufficient, reduced-voltage starting or soft starting methods may also be employed.

- Flexible power supply adaptabilityThe rated voltage is typically6kVcan also be provided according to user requirements10kVSpecifications: Permissible voltage deviation range is±5%

Technical parameters and performance indicators

The TKK series synchronous motors cover a wide range of technical specifications to meet the power requirements of various industrial applications. Below are the main technical parameters of this series:

In addition to the above basic parameters, the TKK series synchronous motors featureLow vibration、Low noiseIt also delivers outstanding performance, thanks to the Simo motor.Precision Dynamic Balancing Calibration与Optimized structural designThe motorRotating componentsHigh machining precision ensures stator-rotor concentricity, thereby reducing vibration and noise during operation.。

III. Structural design and configuration

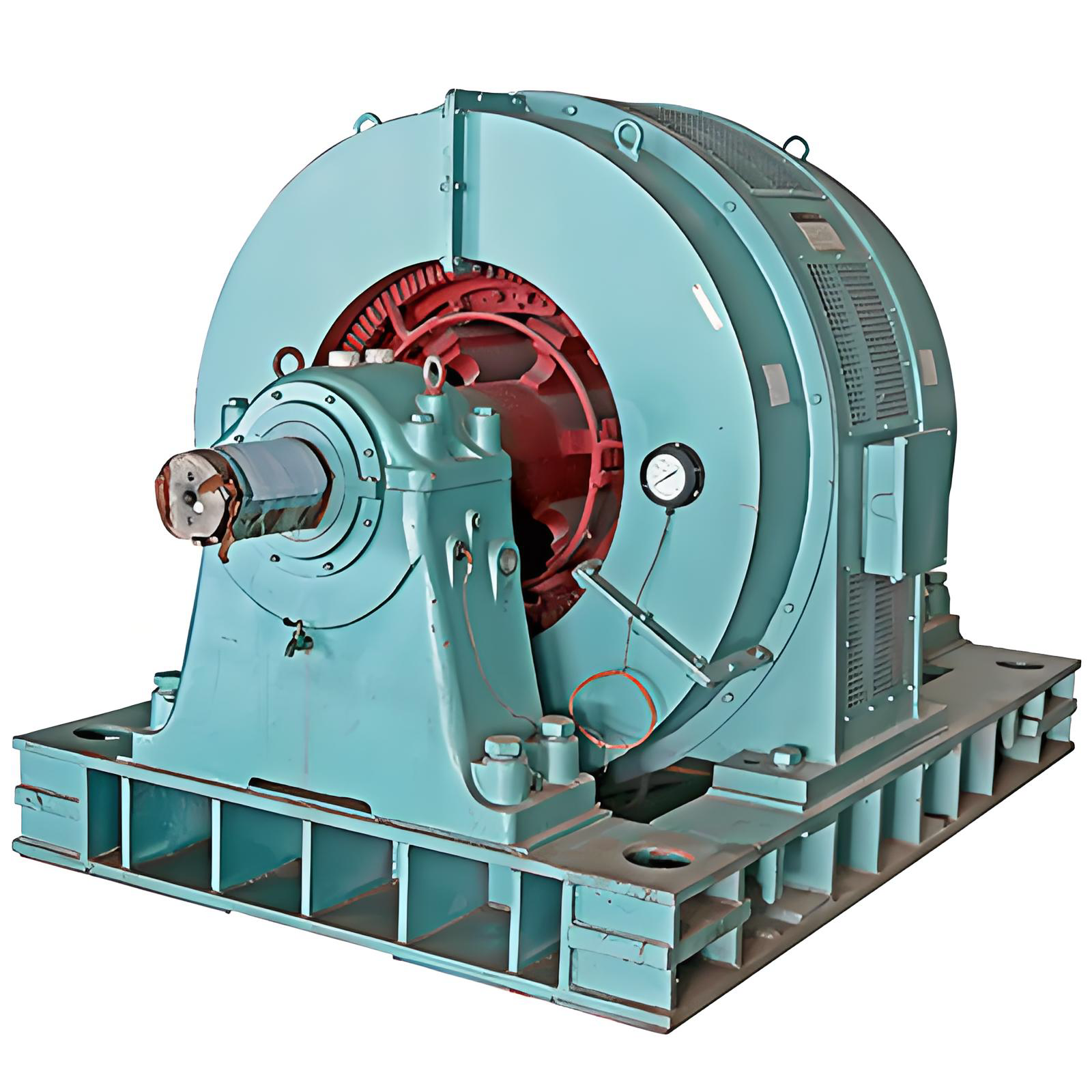

1. Motor body structure

The TKK series synchronous motors utilizeRobust box-type structureEach component is carefully designed and optimized:

- Stand design: AdoptionWelded from high-quality steel plateThe motor components are designed with sufficient strength and rigidity. All motor component designs undergo finite element modeling analysis to ensure excellent dynamic performance.

- Stator structureThe stator core is made ofStacked from 0.5mm-thick low-loss silicon steel laminationsThe core segments are separated by radial ventilation channels, effectively improving heat dissipation conditions.

- Rotor designThe rotor adoptsSpecial damping structureEnhance damping to reduce oscillation. Specialized anti-loosening technology for rotating components ensures secure fastening, preventing sparks and arcs.

2. Bearings and Lubrication System

TKK Series Synchronous Motors are equipped withHigh-Performance Seated Plain BearingFeatures a reliable lubrication system and temperature rise control:

- Bearing Structure:Generally adoptedOil ring structure或Composite Lubrication StructureDepending on the specific structure and load

- Anti-shaft current designThe seat-type bearing is mounted on the base plate, with a centralInsulating matEffectively prevents the generation of shaft currents, protecting bearings from electrical erosion.

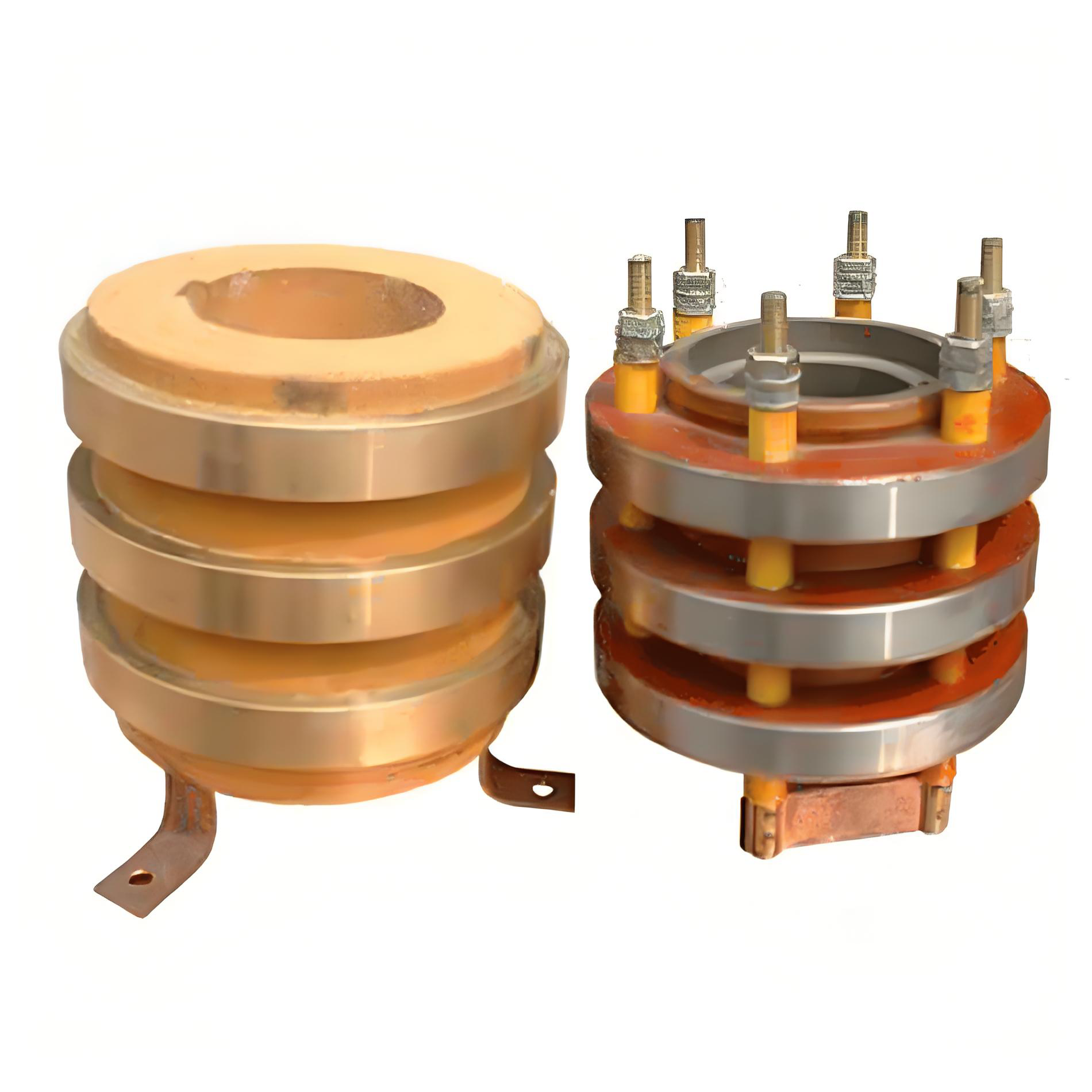

3. Excitation System

The TKK series synchronous motors utilizeAdvanced excitation technologyEnsure stable operation of the motor:

- Thyristor Excitation UnitProvide a stable DC excitation power supply to ensure the motor's operational performance under varying load conditions.

- Brushless Excitation System(Optional): The AC excitation machine and rotating rectifier unit feature a standalone design for easy maintenance and servicing.

IV. Application areas and scenarios

The TKK series synchronous motors, with their reliable performance and robust construction, have found extensive application across numerous industrial sectors:

1. Primary Application Industries

- Petrochemical Industry: for drivingCompressors and Pump EquipmentSuitable for environments requiring resistance to corrosive gases such as acids and alkalis.

- Power industry: Applied toPower Plant Auxiliary Equipment、Water pump systemproviding stable power support

- Mining industry: Specifically designed for transmissionMining Grinding MillincludingGrid-type ball mill, rod mill, coal mill等

2. Typical Application Scenarios

The TKK series synchronous motors are primarily suitable for driving the following equipment:

- Compressor Equipment:especiallyReciprocating Air CompressorThe motor featuresHigh torque, constant speedIts characteristic is that it maintains a constant synchronous speed even under severe load variations.

- Pumps: Used to drive all types ofIndustrial water pumps, circulating water pumpsetc., to meet the requirements of continuous operation

- Fan equipment: Applicable toSupply fan, exhaust fanand other equipment, providing reliable power support

V. Product Advantages and Values

1. High-efficiency energy-saving characteristics

The TKK series synchronous motors deliver significant energy-saving benefits:

- high power factor: Rated power factor reaches0.9 (Ahead of Schedule)Effectively improve power grid quality and reduce investment in reactive power compensation equipment.

- Low-loss design: AdoptionLow-loss silicon steel sheets和Reasonable electromagnetic parametersSignificantly reduce iron losses and copper losses, improving operational efficiency.

2. Operational reliability

The TKK series synchronous motors offer distinct advantages in reliability:

- Powerful startup capability: Has the followingHigh stall torque和TorqueEnsure the equipment starts up smoothly.

- Adequate overheating marginThe insulation system is rated at Class B, but actual insulation materials used are Class F or higher, providing ample temperature rise margin.

- Superior moisture resistance: AdoptionVacuum Pressure Impregnation ProcessThe windings feature excellent moisture resistance and mechanical strength.

3. Ease of maintenance

This series of motors has been designed with ease of maintenance in mind:

- Easily accessible structureRational structural design makes routine inspection, maintenance and overhaul work more convenient.

- Modular ComponentsKey components feature a modular design, reducing spare parts inventory and simplifying replacement procedures.

- Comprehensive monitoring interface: Can be customized according to user requirements, inInstall temperature monitoring devices on critical components such as stator windings and bearings.to monitor the motor's operating status in real time

VI. Installation and use guide

1. Installation Requirements

The TKK series synchronous motors have specific requirements for the installation environment:

- environmental conditions: Suitable for use at altitudeNot exceeding 1000 metersAmbient temperatureNot more than 40°CAn indoor environment with minimal dust, no steam, and no corrosive gases such as acids or alkalis.

- basic requirement: RequiredStrong and level foundationThe motor is designed to withstand the weight of the motor and the mechanical stresses of operation.

- Interoperability RequirementsWhen the motor and driven machinery are connected via a coupling, the motor shaft extensionCannot withstand applied radial or axial forces

2. Electrical connections and configuration

Correct electrical connections are a prerequisite for reliable motor operation:

- Stator lead wiresMultiple cable outlets are provided, with high-voltage cables routed through terminal blocks at the base of the unit. Alternatively, a junction box can be manufactured upon request for wiring connections.

- excitation system: AdoptionThyristor Excitation Unitprovides a stable DC excitation power supply

- Protection ConfigurationAppropriate protective devices, including overcurrent, overload, and undervoltage protection, should be configured based on the motor capacity and system requirements.

VII. Services and technical support

1. Quality assurance systems

Simo Electric has established a comprehensive quality assurance system to ensure the exceptional quality of its TKK series synchronous motors:

- International Standard Certification: ByISO9001 Quality System Certification、ISO14000 Environmental Management System和OHSAS18000 Occupational Health and Safety Management Systemaccreditation

- Strict testing process: In the manufacturing process afterMultiple Turn-to-Turn Impulse Withstand Voltage及Ground Voltage Withstand TestEnsure excellent and reliable insulation performance.

- Comprehensive performance testing: Each motor isRigorous factory testingincluding no-load tests, load tests, and overspeed tests

2. After-sales service commitments

Simo motors provide customers with comprehensive after-sales service guarantee:

- rapid response: Customers who find quality problems in the course of use, upon notification of theResponse within 24 hoursIf on-site service is requiredActivated within 48 hours

- Professional Support: Maintenance personnel will not be withdrawn until the fault is eliminated to ensure that the equipment is returned to normal operation

- Lifetime Service: Once a Simo motor product is soldLifetime Cost WarrantyProvide long-term technical support to customers

The TKK series synchronous motors, with theirExcellent technical performance、Rugged structural design和Reliable operational performancehas become the preferred power solution for numerous industrial sectors. Simo motors achieve this throughContinuous technological innovation和Strict quality controlEnsure that every TKK series synchronous motor delivers reliable performance under demanding operating conditions.Stable and efficientThe power of the support.

Choosing the Simo TKK series synchronous motor means choosingReliable equipment performance和Complete technical servicesWe look forward to collaborating with you to advance technological progress and development in the industrial sector.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206