Simo motors successfully solved the stator winding grounding fault of a chemical plant's 6kV high-voltage motor.

Date: 2023-08-20 Categories: Cases Views: 1050

Excerpt:

This article documents the successful repair of a 6kV high-voltage motor stator winding grounding fault for a large chemical company. Through precise diagnosis and professional repair process, our team not only solved the insulation breakdown problem of the winding, but also established a perfect equipment health management system for the customer through systematic preventive maintenance suggestions. This case demonstrates Simo's technical strength and service quality in the field of 6kV high-voltage motor repair.

Article Catalog[Hidden]

- I. Fault Background: Sudden shutdown, critical production situation

- II. In-Depth Diagnosis: Identifying the Root Cause of the Malfunction

- III. Specialized maintenance programme and implementation process

- IV. Maintenance results and customer value

- V. Case Summary and Professional Recommendations

- VI. Professional Advantages of Xima Motors

I. Fault Background: Sudden shutdown, critical production situation

Customer Information:

- Client OrganizationA major chemical company (name withheld at client's request)

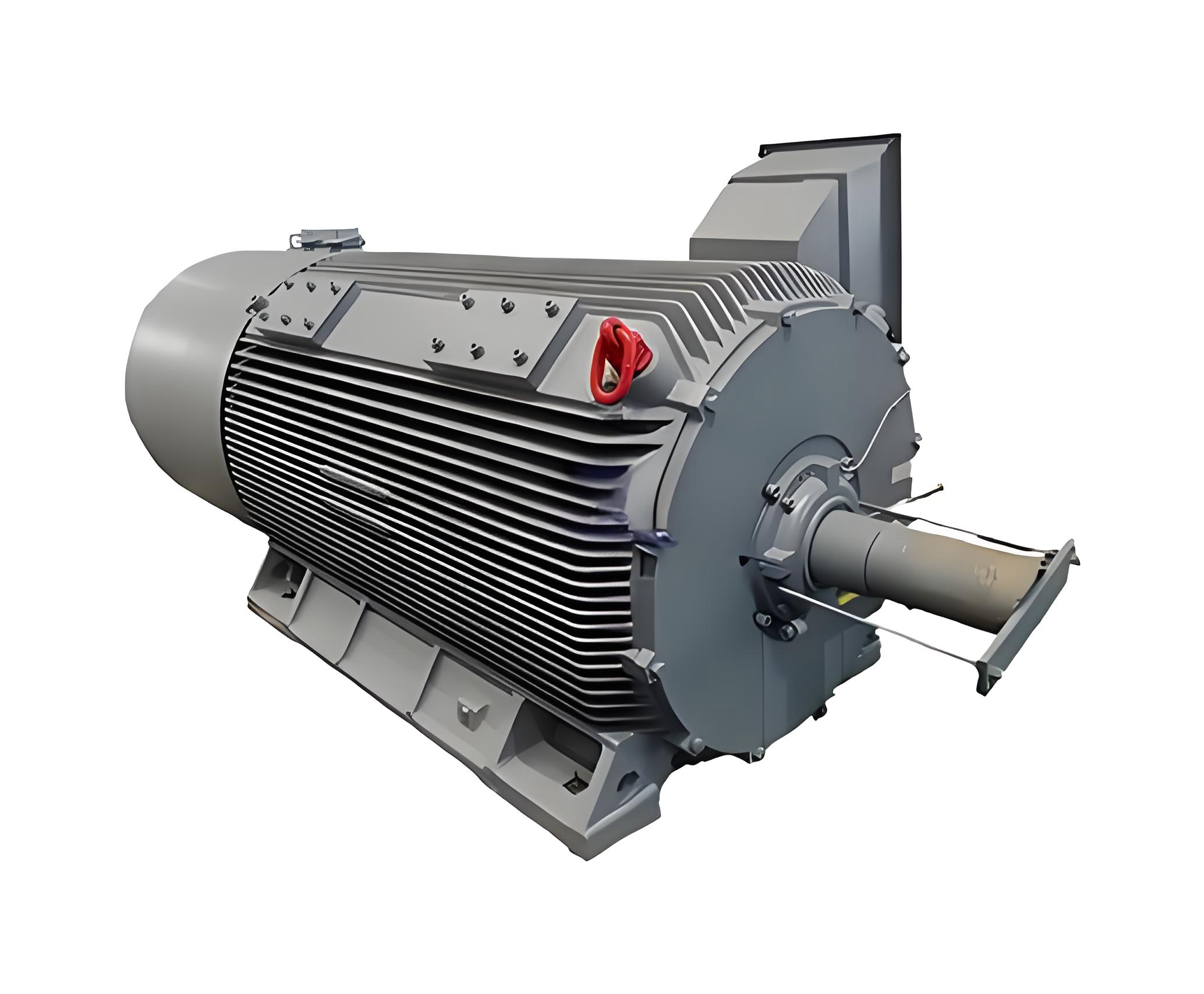

- Equipment Type6kV High-Voltage Asynchronous Motor

- Key ParametersRated power: 710 kW Rated voltage: 6 kV Rated current: 82 A Rotational speed: 2985 r/min

- application scenarioDrive critical process pumps

- Fault Symptoms:

- Sudden trip during operation; relay protection indicates "stator ground fault."

- On-site testing revealed that the insulation resistance of all three-phase windings to ground had dropped to zero.

- Equipment emergency shutdown severely disrupted production processes.

II. In-Depth Diagnosis: Identifying the Root Cause of the Malfunction

Simo motorsUpon receiving the client's urgent request, the technical team arrived on-site within two hours to conduct a systematic diagnosis:

1. Preliminary Testing and Data Analysis

- Using a megohmmeter to measure the winding-to-ground insulation resistance, the reading is below 0.5 MΩ (Standard requirement: not less than 1 MΩ under hot conditions).

- DC resistance testing indicates balanced resistance across all three phases, ruling out winding open circuits and turn-to-turn short circuits.

- Preliminary determination indicates a breakdown of the stator winding's primary insulation to ground.

2. Precision Positioning and Root Cause Analysis

- Scanning the open-circuit point of windings using the open-winding transformer method

- Precise fault location using pulse wave reflection method

- Fault LocationA winding insulation breakdown point was detected 15 cm from the end of the core.

- root cause:

- Long-term operation in humid environments causes moisture ingress and aging of the winding insulation.

- Insulation materials naturally age, resulting in a decrease in electrical strength.

- Recent power grid operational overvoltage surges have become the primary cause of breakdowns.

III. Specialized maintenance programme and implementation process

Based on the diagnostic results, we have developed a detailed repair plan:

1. Faulty Winding Repair and Handling

- Detailed TeardownCarefully remove the faulty winding using specialized tools, taking care not to damage the iron core.

- Insulation treatmentThoroughly clean the groove and remove burrs by sanding with three grades of sandpaper.

- Application of New Materials:Selecting Simate's specially formulated H-class insulation material to enhance heat resistance rating

2. Implementation of Professional Insulation Processes

- Vacuum Pressure Impregnation (VPI): Immersion treatment is performed in specialized equipment to ensure thorough penetration of the insulating varnish.

- High-temperature curingStrictly follow the process curve for temperature ramping and curing to ensure insulation performance.

- Anti-aliasingApply specialized anti-corona varnish to the winding ends to improve the electric field distribution.

3. Comprehensive Testing and Validation

After completing the repairs, we conducted rigorous testing and verification:

- Insulation Resistance TestWinding insulation resistance to ground restored to over 1000 MΩ.

- DC Withstand Voltage TestPassed DC withstand voltage test at 2.5 times rated voltage

- AC Withstand Voltage TestPasses standard power frequency AC withstand voltage test

- No-Load TestNo-load current balance, vibration, temperature rise, and other parameters all meet standards.

IV. Maintenance results and customer value

1. Direct repair results

- The equipment passed its initial test run after being repaired.

- All electrical parameters exceed factory standards.

- It has been operating stably for 8 months without any issues.

2. Value Created for Customers

- Avoid major lossesQuick response minimized production downtime losses for the customer by approximately 1.2 million yuan.

- Performance EnhancementMotor efficiency improved by 21% (TP3T), with an estimated annual electricity savings of approximately 50,000 kWh.

- Life ExtensionAfter maintenance, the equipment's expected service life is extended by more than 10 years.

- Management OptimizationAssist clients in establishing equipment preventive maintenance systems

V. Case Summary and Professional Recommendations

1. Technical Summary

- Accurate fault diagnosis is the key to successful repairs.

- Advanced VPI process ensures insulation treatment quality

- Rigorous testing standards ensure repair reliability.

2. Preventive Maintenance Recommendations

Based on the experience gained from this case, we recommendHigh voltage motorsUser:

- Regular inspection:

- Measure insulation resistance monthly and establish trend analysis.

- Conduct DC leakage current testing every six months.

- Comprehensive preventive trials are conducted annually.

- Operation and Maintenance:

- Keep the motor operating environment dry and clean.

- Monitor bearing temperature and vibration conditions

- Record operational data and establish equipment health records.

- Professional Assurance:

- Select a repair service provider with professional qualifications.

- Establish an emergency repair plan

- Perform regular professional maintenance

VI. Professional Advantages of Xima Motors

This case study demonstrates Xima Electric's core strengths in the field of high-voltage motor maintenance:

- rapid responseOn-site within 2 hours, diagnosis completed within 24 hours

- Professional TeamTechnical experts with over 20 years of experience

- Advanced Processes:Possesses complete VPI equipment and processes

- Quality AssuranceProvides a 12-month warranty period

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206