Article Catalog[Hidden]

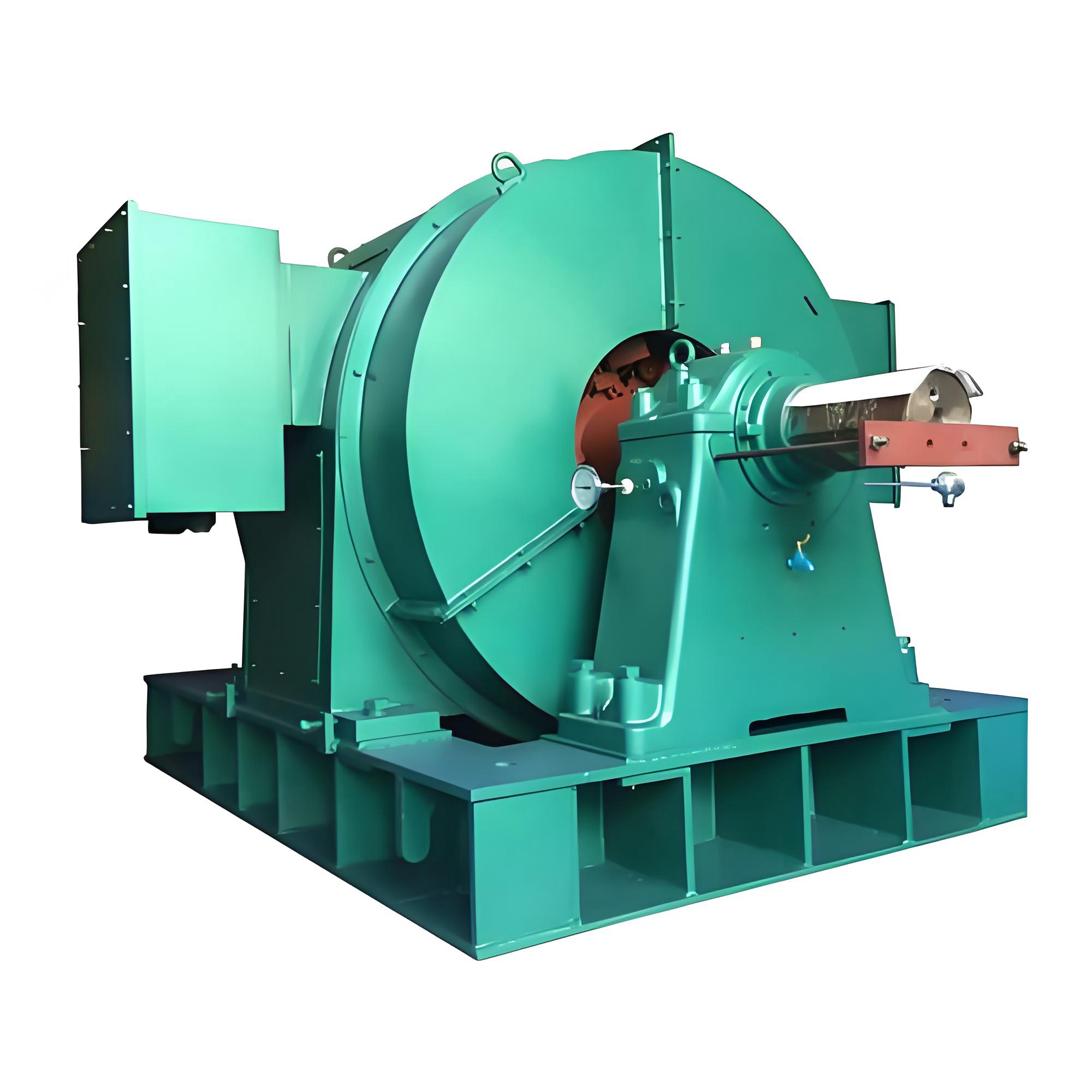

Simo motorsbrush holderThe perfect blend of outstanding performance and enduring stability

In the field of key motor components, Xima motor brush holders are renowned for theirExquisite craftsmanship和superior performancebecoming the preferred choice for numerous industrial equipment.

Simo Motor Brush Holder(also known as brush grip) is specifically designed for various types ofDC motorThe critical component of the design applies pressure via springs to the brushes, which maintain sliding contact with the surface of the commutator or slip ring. This action enables the brushes to function between the stationary and rotating assemblies.Stably conduct electric currentAs a critical component of electric motors, the quality of the brush holder directly impacts the performance and lifespan of the entire motor system.

The brush holder for the Xima motor adoptsQuality materials和Precision Manufacturing ProcesspossessSturdy construction, stable pressure, easy installationThese features make them widely applicable in various industrial motor fields such as metallurgy, power generation, cranes, and traction motors.

I. Core Technical Features

1. Exceptional structural design

The brush holder for the Xima motor adoptsOptimized mechanical structurecan maintain stable operation of the brushes over the long termIts structure primarily consists of:

- Brushing sectionKeep the carbon brush in the specified position, employing precision machining to ensure dimensional accuracy.

- Pressurized sectionApply appropriate pressure to the carbon brush to prevent vibration.

- Framework SectionConnects the brush housing and pressure-applying section to form a complete load-bearing system.

- Fixed SectionSecurely mount the brush holder to the motor to ensure overall stability.

The standard design tolerances for brush box bores strictly adhere to the basic hole system for interference fits: radial tolerance H7 and axial tolerance H11, ensuring proper contact between the brush and commutator.Optimal Clearance。

2. Premium Material Selection

The brush holder for the Xima motor primarily usesBronze castings, aluminum castingsand other high-performance synthetic materialsThese materials possess:

- Excellent mechanical strengthWithstand various mechanical stresses during motor operation

- Excellent machinabilityEnsure precision machining and consistency of all components.

- Corrosion ResistanceAdapt to various harsh industrial environments

- Exceptional thermal performanceEffectively reduce operating temperature and extend service life.

- Stable electrical conductivityEnsure the stability and reliability of current transmission.

3. Precision Manufacturing Processes

The brush holder for the Xima motor adoptsAdvanced processing techniquesEnsure consistent and stable product quality:

- Porous Brush Box ProcessingUse multiple broaches or push broaches for simultaneous machining to ensure concentricity after processing. The concentricity tolerance for multi-hole brush boxes shall not exceed 0.36 mm.

- Surface treatment technologyDepending on the application environment, surface treatments such as nickel plating, zinc plating, chrome plating, imitation gold plating, copper plating, chemical oxidation, and acid pickling may be employed.

- Strict quality controlAvoid defects such as sharp corners and burrs on the box body, as these imperfections can cause electrical discharge in humid environments.

II. Performance Advantages

1. Stable and reliable operational performance

The brush holder of the Xima motor ensures long-term stability of the brushes, guaranteeing the motor'sUnder various operating conditionscan all operate stablyIts unique design facilitates easy installation and removal of brushes within the brush housing during inspection or replacement, significantly simplifying the maintenance process.

The brush holder can adjust the exposed portion of the brush beneath the brush holder (the gap between the lower edge of the brush holder and the surface of the commutator or slip ring), effectivelyPrevent wear on the commutator or slip rings。

2. Optimized Pressure Control System

The pressure control system of the brush holder for Xima motors has undergonePrecision calculations and testingensure that the brush maintains contact with the commutator or slip ring.Optimal Contact Pressure:

- Pressure of carbon brushes for motors in metallurgy, power generation, cranes, and other applications: 0.15 to 0.35 kg/mm²

- Pressure of Carbon Brushes for Traction Motors: 0.3 to 0.4 kg/mm²

- Pressure ConsistencyThe pressure error of the carbon brush holders on the same motor shall not exceed 10% to ensure uniform current density and prevent local overloading.

3. Long service life

Xima Motor Brush Holder relies onPremium materials和Precision Manufacturing ProcesspossessExtremely long service lifeThe brush grip should rotate smoothly with finger pressure. When lifted, it should fall freely without any dead spots or sticking. All joints must be securely riveted with no risk of disconnection.。

III. Application Areas

Simar motor brush holders are widely used in the following fields:

1. Heavy industry

- Metallurgical industryRolling mill motors, smelting equipment, and other heavy-duty motors

- Power Generation IndustryGenerator sets, auxiliary equipment motors

- Lifting equipmentLifting Mechanism for Bridge Cranes and Gantry Cranes

2. Transportation Sector

- traction motorElectric Locomotives and Urban Rail Transit Traction Systems

- Electric vehiclesDrive motors for various types of electric vehicles

3. Industrial Manufacturing Sector

- Machine ToolsDrive motors for various industrial processing machine tools

- PumpsIndustrial water pumps, hydraulic systems, etc.

- Compressor EquipmentAir compressors, refrigeration compressors, etc.

IV. Technical Specifications

V. Installation and Maintenance

1. Installation Key Points

The brush holder of the Xima motor is designed with optimal rationality.Quick and easy installationThe parallelism tolerance between the fixed face of the brush holder and the centerline of the brush box, as well as the spacing tolerance, are both: A = ±0.2 mm.During installation, ensure that the bottom surface of the brush box hole is perpendicular to the brush box wall and perpendicular to the mounting surface, with a maximum perpendicularity tolerance of 0.25 mm.。

2. Maintenance Guide

Maintenance of the Simar motor brush holder is simple and convenient:

- Regular inspectionRegularly check for changes in brush holder pressure to ensure it remains within the normal range.

- Wear MonitoringMonitor the wear condition of the brushes and replace worn brushes promptly.

- Pressure adjustmentOver time, elasticity will fatigue and diminish. Excessive deterioration may cause sparking at the base of the carbon brushes. Adjust the pressure promptly.

VI. Troubleshooting and Resolution

Frequently Asked Questions and Solutions

- Spark PhenomenonThe spring pressure may be insufficient; adjust the pressure to the specified range.

- Uneven brush wearCheck whether the brush holder pressure is uniform. The pressure deviation of the carbon brush holders on the same motor should not exceed 10%.

- Abnormal VibrationCheck whether the brush holder is securely fastened and whether all components are reliably connected.

VII. Service Support

Xima Motors provides customers withComprehensive technical support services:

- Technical ConsultationProvide professional selection recommendations and technical guidance.

- Installation GuideProvide detailed installation and usage instructions.

- After-sales Support:Provide comprehensive quality assurance and after-sales service

- Technical SupportAssist in resolving technical issues encountered during use

The brush holder for the Xima motor featuresExquisite craftsmanship、Stable performance和Extended service lifebecome various types of motorsIdeal choiceWhether you are an electric motor manufacturer or a maintenance technician, choosing Xima motor brush holders will provide reliable operation for your equipment.Reliable Protection。

We are committed toContinuous technological innovation和Strict quality controlto provide customers withThe finest products and servicesChoosing Xima Motor Brush Holders means choosing to enhance equipment operational reliability and reduce maintenance costs.Reliable quality和Reliable service。

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206