Simo Motor Successfully Solves Persistent Vibration Faults in 900kW High Voltage Motors

Date: 2023-08-21 Categories: Cases Views: 2244

Article Catalog[Hidden]

I. Trouble background: stubborn vibration, affecting production

Device Information:

- Customer Name: Sanmenxia Tengyue Tongli Cement Co.

- Equipment Model: YR500-4 Simo High Voltage Synchronous Motor

- Key Parameters: rating900kWRated Voltage10kVEquipment weight 5.9 tons

- Core issues: When the motor is runningVibration value exceeds the standardconcomitantabnormal noiseVibration and high temperatures in the slip ring area.

- Historical situation: The motor had been commissioned for maintenance in early 2020, but theFailure to solve the problem completelyThe production stability and safety of the equipment are seriously affected.

II. In-depth diagnosis: exploring the root causes of vibration

In the face of this recurring and persistent failure, theSimo motorsWhen the maintenance team took over, they did not dismantle it immediately, but first carried out systematic data collection and cause analysis:

- Field data collection: Engineers use portable vibration analyzers to capture multi-directional vibration spectra at key points such as motor bearing housings and pedestals.

- Historical record analysis: Review previous service records to rule out routine bearing wear or shallow causes such as poor alignment.

- Comprehensive Fault Determination: Combining spectral characteristics with extensive field experience, the team initially determined that the root cause of the fault may lie in theRotor balancing misalignment或Hidden damage to rotor cage barsThe problem can not be solved by simply replacing the bearings. This type of problem cannot be solved after simply replacing the bearing and must be returned to the factory for in-depth testing and calibration.

III. Specialized maintenance programme and implementation process

Based on the diagnosis, we developed and implemented a thorough repair program that went far beyond routine maintenance:

1. Full dismantling and inspection at the factory

- The motor will be transported back to the specialized maintenance workshop of Simo Motor with perfect conditions for standardized disassembly.

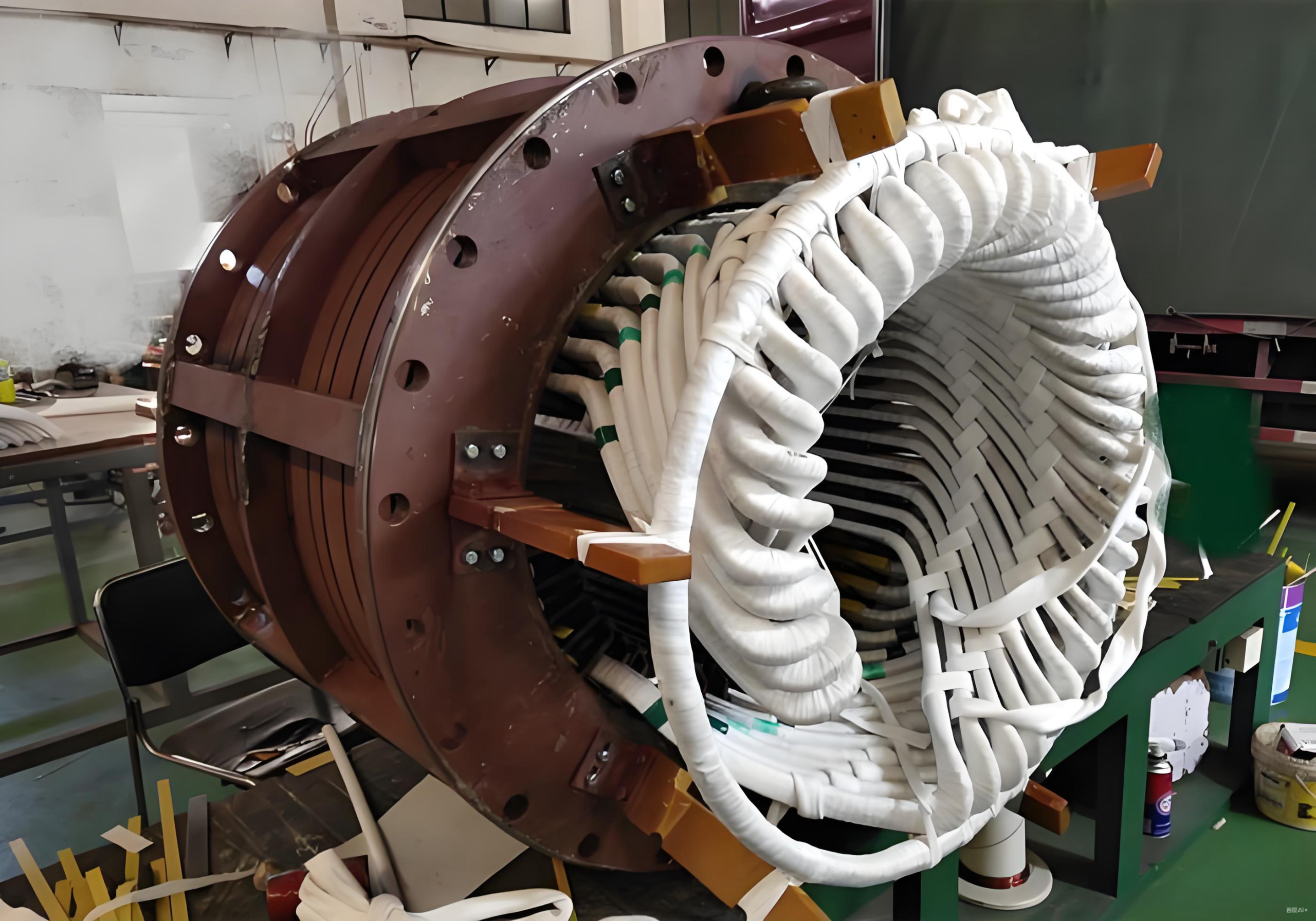

- For stator windings, rotorComprehensive routine testing and inspection。

- Focus on rotorsPrecision Dynamic Balance Test, accurately quantifies the amount of unevenness and phase.

2. Core troubleshooting

- Rotor dynamic balance correction: On a high-speed dynamic balancing machine, the rotor is finely counterweighted to strictly control the amount of residual unbalance below the ISO G1.0 class, eliminating the source of vibration excitation from the root.

- Bearing chamber replacement: Although the bearings were not the main cause of this failure, the front and rear of the motor were still replaced as planned in order to safeguard the overall operating life.Bearing chamber for replacement。

- Comprehensive maintenance: A complete maintenance process of cleaning, painting and assembling the motor ensures that the equipment looks new.

3. Rigorous testing and validation

After the repair was completed, several tests were performed at the factory to ensure the problem was eradicated:

- Insulation resistance test: Insulation resistance of the winding to ground and between phases far exceeds the standard (the new motor standard requires insulation resistance of more than 5 megohms).), confirm that the insulation system is intact.

- Rotor dynamic balance verification: Once again on the balancing machine to verify, the data perfectly meets the standard.

- Trial run: No-load test run smoothly, vibration, temperature rise, noise and other parameters are normal.

IV. Maintenance results and customer value

- The fault is completely eradicated: The motor is put into operation after it has been reassembled andVibration and rattling problems have completely disappearedThe slip ring operating temperature returned to normal. After this motor repair project was put into operation, the equipmentstable operationThe problem is solved.。

- Guaranteeing stable production: It provides a reliable guarantee for the continuous and efficient operation of the customer's production line and avoids the huge economic loss caused by unplanned downtime.

- Earn long-term trust: With this excellent maintenance service, Simo Electric won the deep recognition from the customer. The customer was satisfied with the technical strength and service quality of Simo Motor.。

V. Case summary and inspiration

1. Core message

- Precise diagnosis is the soul: For recurring complex failures, one must rely onProfessional instruments and experienceWe conduct in-depth analysis to find the root cause rather than dealing with superficial phenomena. The Simo motor repair team arrives on-site quickly after receiving a repair report and initiates systematic troubleshooting.

- Technical strength is the foundation: Solving core problems such as rotor dynamic balancing requiresPrecision equipment (e.g., high-speed balancing machines) and standardized technical process, which is the essential gap between ordinary maintenance teams and brand manufacturers. Simo Electric has professional overhaul workshop and testing equipment.。

2. ToHigh voltage motorsManagement recommendations for users

- Establishment of a preventive maintenance system: Regular monitoring of motor vibration, temperature, insulation resistance and other key parameters, creating equipment health profiles for predictive maintenance.

- Choose your repair service provider carefully: The repairer should have the appropriate capabilitiesSimo provides customers with comprehensive on-site technical support and maintenance work, and is able to provide a guarantee for the quality of maintenance. Simo motors provide customers with comprehensive on-site technical support and maintenance work。

- Focus on the quality of the repair and not just the price: An incomplete repair can lead to greater losses in production downtime, and it is more important to consider technical strength, workmanship standards and warranty commitments.

(Call to Action CTA)

Are your high-voltage motors facing vibration, insulation aging, performance degradation and other “difficult problems”? Are you looking for a solution that can provideLifetime technical support and reliable quality assuranceThe maintenance partner?

Contact the Simo Motors expert team todayGet a free technical consultation and initial equipment health assessment! We are committed to providing the same professional and rigorous high voltage motor repair, maintenance and full life cycle management services as in this case.

Xi'an Simo Motor -- Your expert for high-voltage motor system solutions

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206