Leading the Green Power Revolution: High-Efficiency Energy-Saving Motors Help Businesses Reduce Costs and Increase Efficiency

Date: 2025-12-09 Categories: Company News Views: 9923

Excerpt:

High-Efficiency Energy-Saving Motors: A Critical Step for Enterprises to Break Free from the “Energy Consumption Siege” Under the dual pressures of the “dual carbon” goals and rising energy costs, the industrial manufacturing sector faces unprecedented challenges. For many factory managers, monthly electricity bills are often staggering, with the biggest “power guzzlers” lurking in every corner of production lines—namely, motor systems.Statistics reveal that motor systems consume 60% of industrial electricity usage.

Article Catalog[Hidden]

Energy efficient motorsA Critical Step in Helping Enterprises Break Through the “Energy Consumption Siege”

Under the dual pressures of the “dual carbon” goals and rising energy costs, the industrial manufacturing sector faces unprecedented challenges. For many factory managers, monthly electricity bills are often staggering, with the biggest “energy hogs” lurking in every corner of the production line—namely, motor systems.Statistics show that motor systems consume over 60% of industrial electricity usage. Therefore, reducing energy consumption at the source has become an essential task for enterprises seeking to cut costs and improve efficiency. At this juncture,Energy efficient motorsNo longer merely an environmental concept, it has become an “invisible gold mine” for enterprises to enhance their core competitiveness and achieve green transformation.

Core Technology: More Than Just “Power Saving”

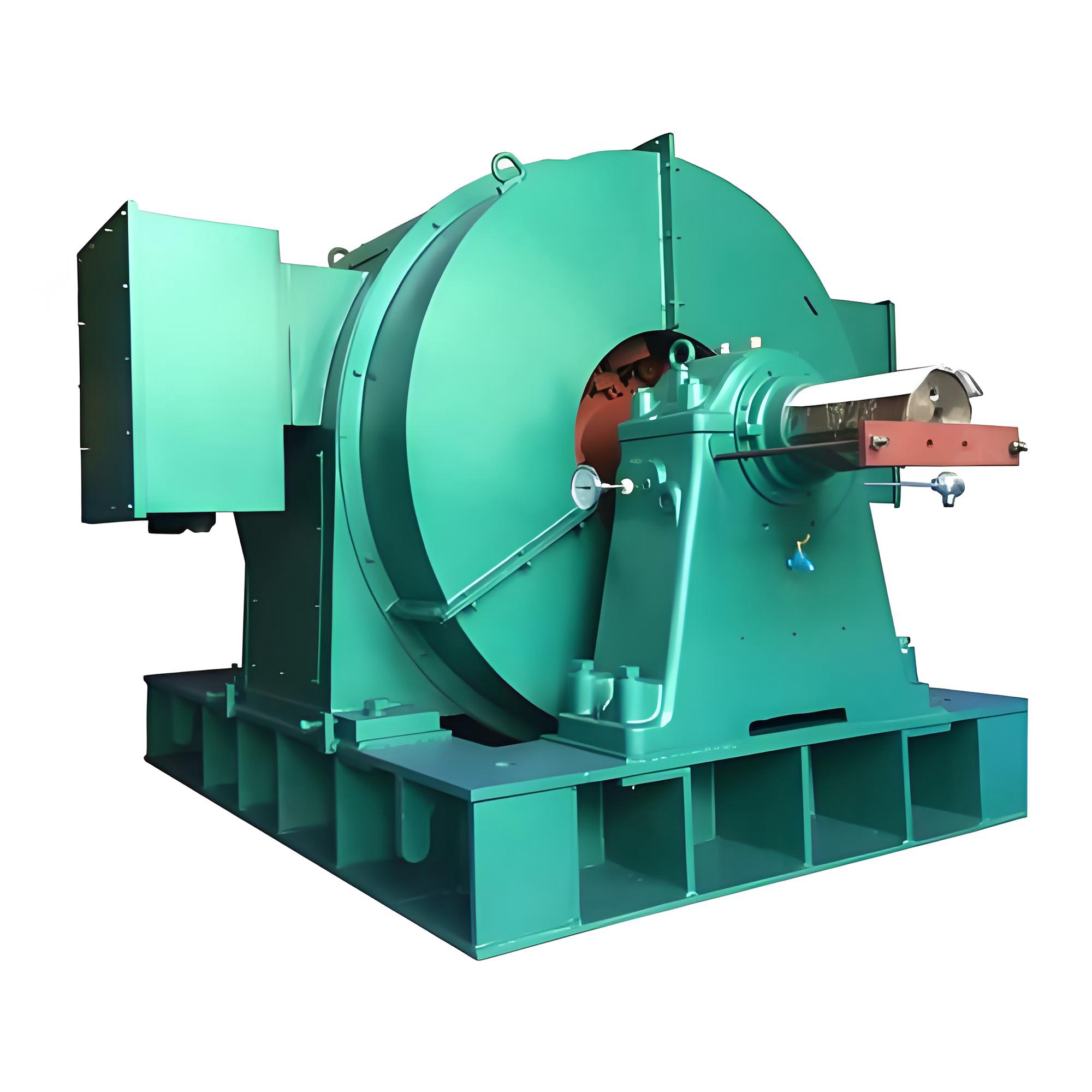

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2023/08/1763940120-0258.png)

So-calledEnergy efficient motorsHigh-efficiency motors represent not merely conceptual packaging, but a profound innovation rooted in materials science and design engineering. Compared to conventional motors (such as the outdated Y series), they typically employ low-loss cold-rolled silicon steel sheets with high magnetic permeability, alongside optimized electromagnetic designs and ventilation structures.

The direct result of this technological upgrade isSignificantly reduced various lossesincluding copper losses, iron losses, and mechanical losses. From a technical standards perspective, the currently mainstream IE3 (super-efficient) and IE4 (super-super-efficient) rated motors on the market achieve efficiency gains of 31% to 101% over conventional motors. This means that for the same output power,Energy efficient motorsConsumes less electrical energy and generates lower heat, thereby extending the lifespan of the insulation system and enhancing the stability of equipment operation.

Doing the Math: The Cost Advantage Over the Entire Lifecycle

Many procurement professionals faceEnergy efficient motorsHowever, many are deterred by the slightly higher initial purchase price compared to conventional motors. This represents a classic case of “short-sighted” misconception. In the motor's total lifecycle cost (LCC), the purchase price typically accounts for less than 51% of the total, while maintenance expenses constitute an extremely small proportion.The cost exceeding 951 TP3T is actually attributable to the electricity consumed during its operation.。

This is the famous “iceberg theory.” If we crunch the numbers: for a 55kW motor running continuously, improving its efficiency by 4% over a year can recoup the purchase price difference within one to one and a half years through electricity savings. Every year thereafter, the savings become pure profit for the enterprise.Net profit。

Case Study: Energy-Saving Retrofit at a Chemical Plant

To illustrate the results more clearly, let's examine a real-world retrofit case. A medium-sized chemical plant in China faced severe energy consumption issues, with its circulating water pump system relying on outdated IE1-standard motors for years. After implementing an energy management solution, the plant decided to replace all 20 conventional motors in its core areas withYE4 Series High-Efficiency Energy-Saving Motors。

The modified data shows:

- Current dropUnder equivalent load conditions, the operating current decreased by an average of 12%.

- Temperature decreaseMotor temperature rise decreased by 10°C, resulting in a significant reduction in equipment failure rates.

- Returns are astonishingAfter calculation, this project saves approximately 450,000 yuan in annual electricity costs. After deducting equipment procurement and installation costs, the factory hasThe entire investment was recouped within 11 months.。

How to Scientifically Select High-Efficiency Motors?

AlthoughEnergy efficient motorsThe advantages are evident, but blindly following trends must be avoided in practical applications. When selecting equipment, enterprises must consider their specific load characteristics. For instance, in scenarios involving long-term low-load or variable-load operation, simply replacing the motor may yield limited results. It is recommended to combine this withVariable Frequency Drive TechnologyUsed together to achieve optimal system-level energy efficiency. Additionally, attention must be paid to the motor's power factor to avoid reactive power losses caused by over-sizing the motor for the load.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206