Excerpt:

Xi'an TaiFu Xima YRKS Series Wound-Rotor Air-Cooled High-Voltage Motors deliver substantial starting torque with minimal starting current. They are ideal when: - Feeder line capacity is insufficient for starting squirrel-cage rotor motors - Starting time is prolonged or starts occur frequently - Small-range speed regulation is required Applications include: - Driving hoists, rolling mills, wire drawing machines, etc.

Article Catalog[Hidden]

- Professional Guide to Xi'an TaiFu Xima YRKS Series Wound-Rotor Air- and Water-Cooled High-Voltage Motors

- Product Model Analysis: Accurately Identify Motor Specifications

- Product Technology Overview: Professionally designed to meet heavy-duty industrial demands.

- Core Technology Advantages: A Solid Foundation for Exceptional Performance

- Xi'an Simo Motor's Perfect Quality Assurance System

- Ordering guide and technical parameters

- Professional Selection Advice

- concluding remarks

Xi'an TaiFu Xima YRKS Series Wound-Type Air-Water CooledHigh voltage motorsProfessional Guide

Innovative air-water cooling technology combined with a wound rotor design delivers robust power for heavy-duty industrial applications.

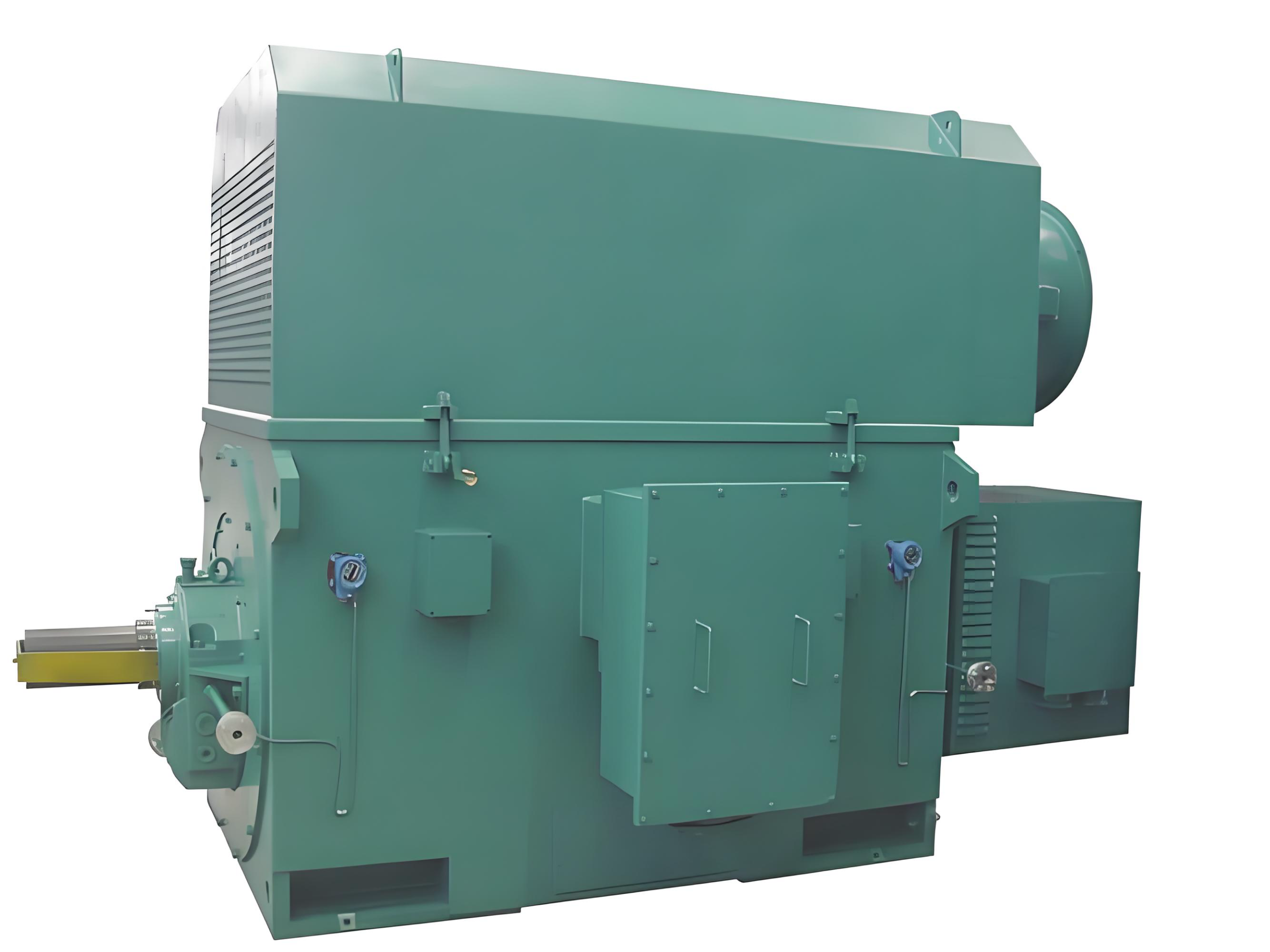

Xi'an TaiFu Xima YRKS Series Wound-Rotor Air/Water-Cooled High-Voltage Motors are specifically designed forHeavy Industrial ApplicationsHigh-performance power equipment developed. This series of motors adoptsAdvanced Wound Rotor Technology与High-Efficiency Air-Water Cooling SystemThe perfect combination, maintaining performance even under demanding conditions.Outstanding operational performance和Outstanding energy efficiencyIt has become the ideal power choice for industries such as mining, metallurgy, and building materials.

Product Model Analysis: Accurately Identify Motor Specifications

Xi'an TaiFu Xima YRKS Series Wound-Rotor Air/Water-Cooled High-Voltage Motors employ standardized naming conventions. Taking YRKS7101-4 as an example:

- "YRKS logoThree-phase asynchronous motor with wound rotor representing closed-type air-water cooled units

- "Code "7101"The first three digits "710" indicate a frame center height of 710mm, while the final digit "1" represents core length No. 1.

- "4" poles: Indicates that the number of poles of the motor is 4 poles

The naming system strictly followsJB/T7594-1994 Technical StandardEnsure users can quickly and accurately identify key product parameters, providing a reliable basis for equipment selection.

Product Technology Overview: Professionally designed to meet heavy-duty industrial demands.

Core technical characteristics

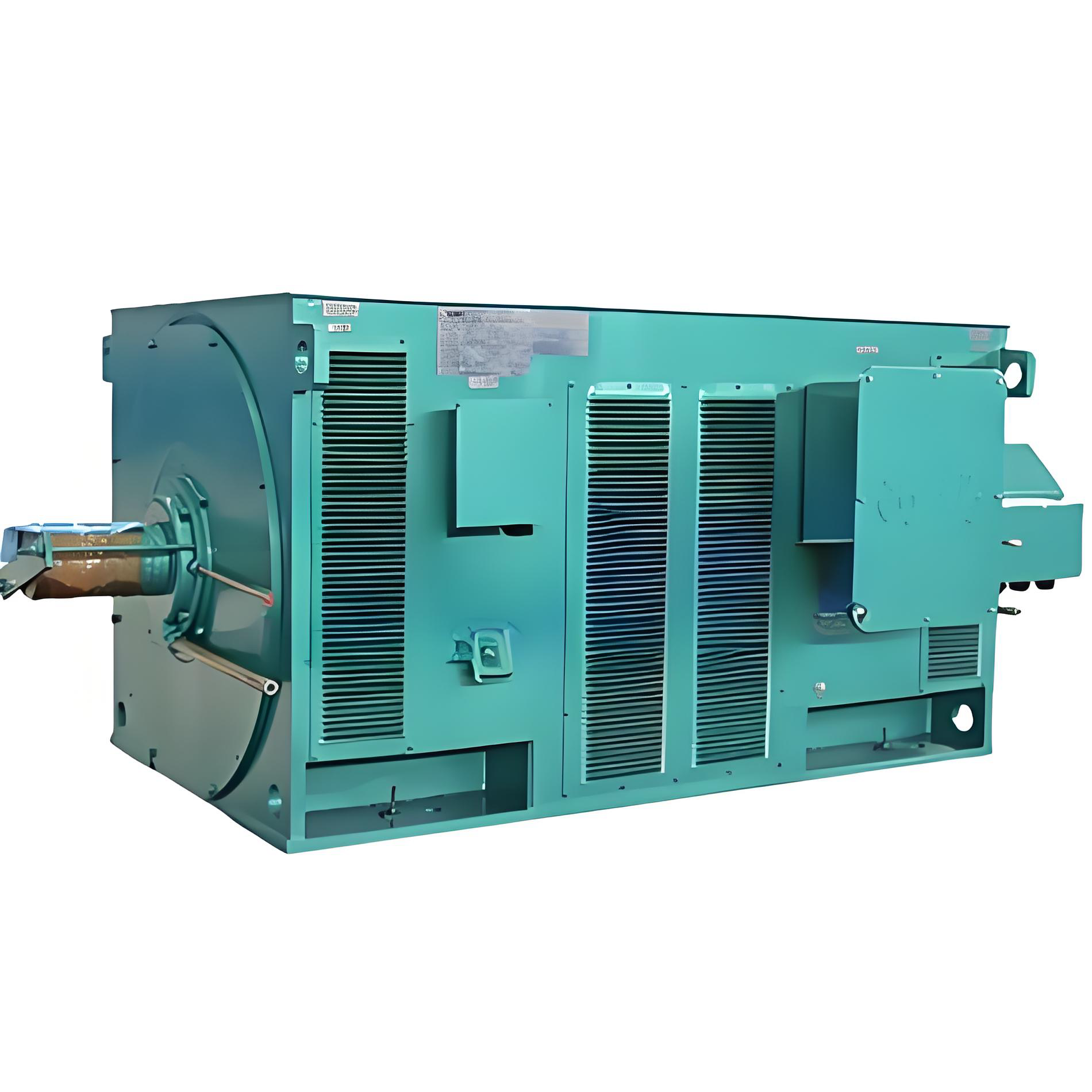

YRKS Series Three-Phase Asynchronous Motors (Center Height 710-1000) 10KV Wound-Rotor Three-Phase Asynchronous Motors AdoptInnovative air-water cooling technologyThe motor series features an IP44 or IP54 protection rating and employs ICW81A cooling. Its specially designed 10kV voltage rating enables direct integration into 10kV power grids, offeringSimplify equipment configuration, reduce investment costs, and lower operational energy consumption.and other significant advantages.

Superior Insulation System

The stator winding is made ofPremium Class F Insulation MaterialThe winding ends are secured using a reliable binding process. During manufacturing, they undergoMultiple Interturn Pulse Voltage Tests及Ground Voltage Withstand Testand treated using imported advanced vacuum pressure impregnation (VPI) solvent-free varnish technology. This advanced insulation treatment ensures the motor possessesExcellent insulation properties、Excellent mechanical strength和Strong moisture-proof capability。

The rotor windings are composed ofWound with high-purity copper materialThe rotor is constructed using F-class insulation material, ensuring reliability under high-speed operation and heavy-load conditions.

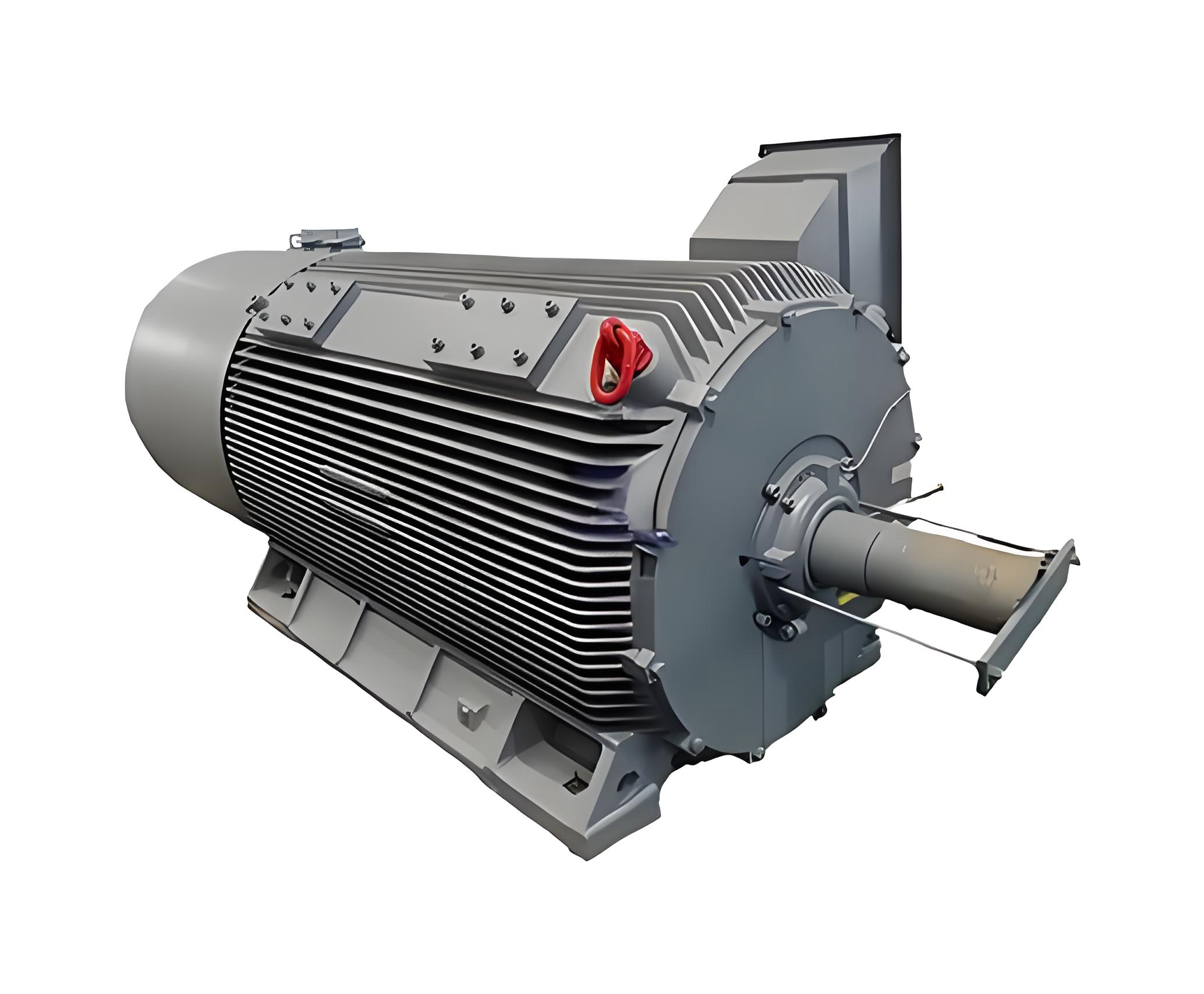

Flexible bearing configuration

The YRKS series motors provide options tailored to different power and speed requirements.Rolling bearings and sliding bearingsTwo configuration options. The H710-800 motor employsProfessional Sliding Bearing StructureEnsures stable operation under heavy load conditions. The basic protection rating is IP44, and customized solutions for other voltages, frequencies, and protection ratings can be provided according to customer requirements.

Core Technology Advantages: A Solid Foundation for Exceptional Performance

Innovative Air-Water Cooling System

The YRKS series motors employ the ICW81A cooling method, which utilizesHigh-efficiency air-water heat exchangerAchieve optimal heat dissipation. Compared to traditional cooling methods, air-water cooling systemshigh temperature environment和confined spaceIt performs exceptionally well, ensuring the motor maintains a stable operating temperature under continuous high-load conditions.

Excellent starting and speed regulation performance

YRKS Series Wound-Type Air-Cooled High-Voltage Motors featureOutstanding starting characteristicsIt can deliver high starting torque with low starting current, making it particularly suitable for:

- When grid capacity is limited and cannot support the starting of squirrel-cage rotor motors

- Heavy-duty equipment requiring frequent or prolonged startup

- Industrial applications requiring speed regulation within a specified range

- Heavy-duty winch equipment, rolling mill units, wire drawing machinery, and other specialized equipment

Robust box-type structural design

The motor adoptsHigh-strength box-type structureIt possesses excellent mechanical strength and rigidity. The installation type is IMB3, designed for continuous operation (S1) under continuous duty, ensuring the motor can withstand various harsh industrial environments.

Energy-saving and environmentally friendly design

Through the combination of optimized electromagnetic design and advanced cooling technology, the YRKS series motors achieveEfficient Energy Utilization和Low-noise operationLow vibration, lightweight, while maintaining reliable performance, meeting the stringent requirements of modern industry for energy efficiency and environmental protection.

Xi'an Simo MotorPerfect Quality Assurance System

Enterprise strength display

Simo motors(Group) Co., Ltd. asA leading enterprise in China's electric motor manufacturing industryThe company specializes in large and medium-sized, high and low voltage, crossDC motorThe research and development and manufacture. The company has built a complete industrial chain system, integrating motor design and manufacturing, electrical control, machining, mold manufacturing, casting process and transportation service, providing customers withComprehensive powertrain solutions。

Authoritative certifications and honors

- Quality Management SystemISO 9001 Quality Management System Certification

- Environmental and Safety ManagementISO 14000 Environmental Management System and OHSAS 18000 Occupational Health and Safety Management System Certification

- International product certificationMandatory certifications: European "CE", American "UL", and Chinese "CCC"

- Industry standingChina's Top 500 Machinery Enterprises, Top 100 Electrical Equipment Manufacturers

- Product quality honorQuality and Credit AAA Grade Enterprise, "Ministry, Province and Municipality Famous Brand Product", "Xi'an Inspection-free Product", "China Light Famous Brand Product" and other honorary titles.

Rigorous commitment to quality

- Strict quality standardsStrictly adhere to national and international standards, manufacture and inspect products in accordance with contractual technical requirements, and ensure that non-conforming products never leave the factory.

- Comprehensive performance testingAfter final assembly, the product must undergo a 72-hour continuous operation test, passing rigorous core performance tests and reliability tests to ensure stable and dependable product performance.

- On-time delivery guaranteeUnder normal sales conditions, products shall be delivered strictly in accordance with the contractually agreed timeframe. In special circumstances, early delivery may be arranged through mutual agreement.

- Timely after-sales serviceRespond to customer inquiries within 24 hours, initiate on-site service within 48 hours, and ensure technicians remain on-site until the issue is resolved.

- Perfect three packages policyProducts with quality issues are covered by the warranty policy. Products that still fail to meet factory specifications after repair will be replaced or refunded.

- Lifetime warranty supportProducts come with a lifetime cost-based warranty after purchase, providing customers with long-term technical support.

Ordering guide and technical parameters

Standard configuration parameters

| parameter category | norm |

|---|---|

| Motor Model | YRKS7101-4 |

| Installation | IMB3 |

| rating | 2800 kW |

| protection class | IP44 or IP54 |

| rated voltage | 6000V |

| Cooling method | IC01 |

| Rated frequency | 50Hz |

| Insulation class | F |

| synchronous speed | 1500r/min |

| environmental conditions | Altitude 1000m, ambient temperature 40°C |

Important Notes

- Direction of RotationThe motor rotates clockwise by default (when viewed facing the shaft extension).

- Transmission Limitations4-pole motors must not be driven by pulleys. If pulley drive is absolutely necessary, consult the manufacturer.

- Technical StandardsThe product is manufactured in strict compliance with the technical specifications of JB/T7594-1994.

Ordering Process Guide

- Standard ordering process:

- Check product samples to determine the model number and specifications of the required product.

- Prioritize standard specification products to reduce costs and shorten delivery cycles.

- Clearly specify the motor model, power rating, voltage, frequency, and other key parameters in the purchase contract.

- Customized for special needs:

- Special requirements need to be clearly marked in the contract

- Support for custom requirements such as other voltage ratings and special protection ratings

- All special requirements must be communicated with the factory's technical department in advance to confirm feasibility.

Professional Selection Advice

When selecting the appropriate YRKS series wound-rotor air-cooled high-voltage motors, it is recommended to focus on the following factors:

- Load Characteristic AnalysisIncluding load type, starting frequency, load inertia, and whether speed regulation capability is required.

- Grid Condition AssessmentVoltage level, grid capacity constraints, and voltage fluctuation range

- Work Environment ConsiderationsEnvironmental factors such as ambient temperature, humidity, altitude, and water quality conditions

- Installation space limitationsInstallation Site Dimensions and Cooling Water Supply Requirements

- Maintenance RequirementsExpected maintenance cycle and maintenance convenience requirements

For heavy-duty industrial applications requiring high starting torque, limited grid capacity, or a specific speed range, the YRKS series wound-rotor air- and water-cooled high-voltage motors areThe most ideal choice。

concluding remarks

Xi'an TaiFu Xima YRKS Series Wound-Rotor Air- and Water-Cooled High-Voltage Motors, with theirInnovative technical design、Superior cooling performance和Reliable operational performanceXima Motors has become an indispensable power solution in numerous heavy industrial sectors. Leveraging robust technical expertise and a comprehensive service system, Xima Motors provides each customer withProfessional technical support和Timely after-sales serviceGuarantee.

For detailed information on the technical specifications of the YRKS series wound-rotor air- and water-cooled high-voltage motors, or to receive personalized selection recommendations, please contact the professional technical team at Xima Electric. We are committed to providing you with comprehensive service support.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206