6kV high-voltage motors: the core engine of industrial drives

Date: 2023-08-21 Categories: Industry News Views: 934

Excerpt:

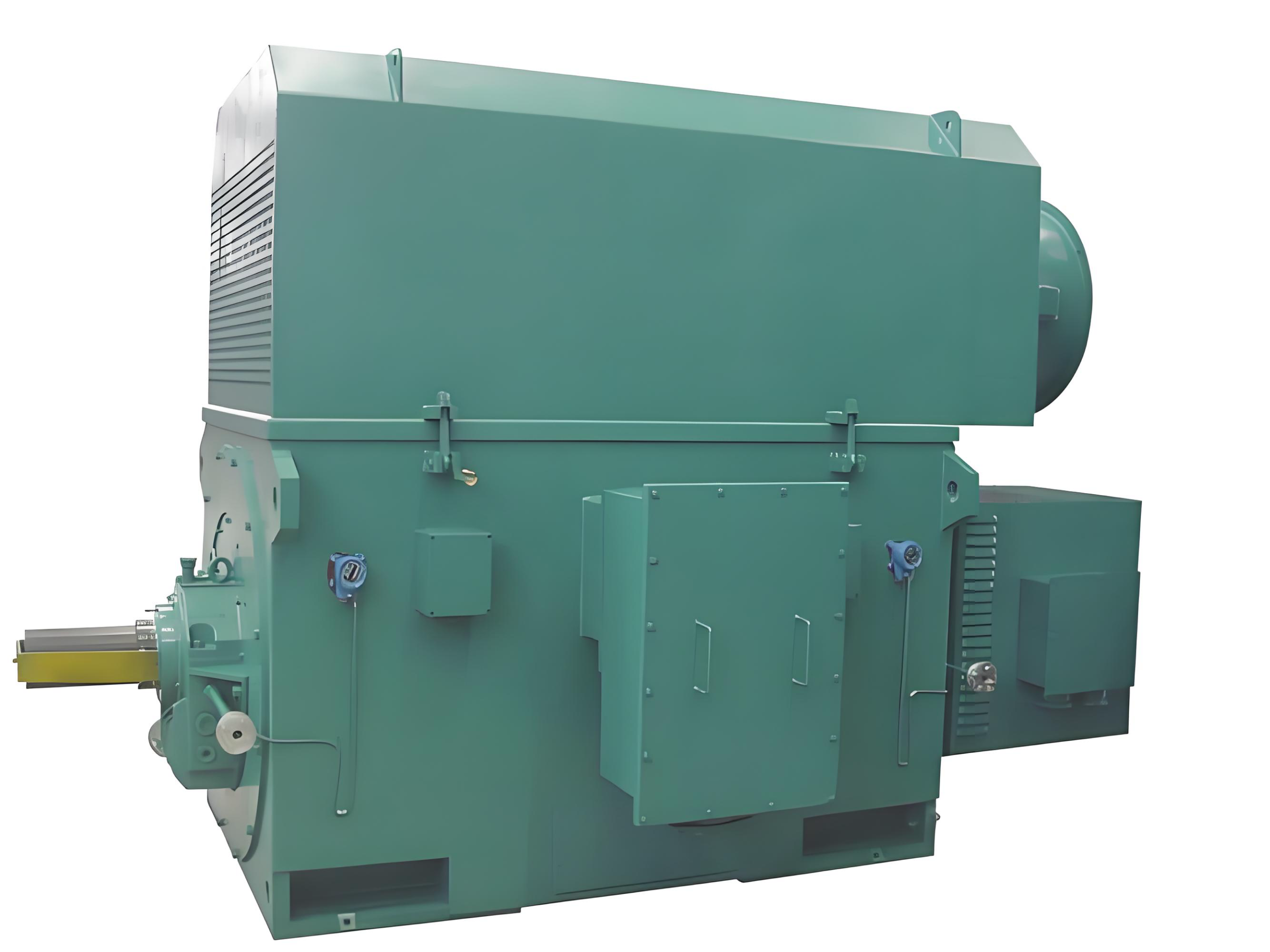

6kV high voltage motor

Article Catalog[Hidden]

💡 6kV high voltage motor: the core engine of the industrial drive

🌟 Introduction: the core engine of the industrial drive

In modern industrial development, as the power source of mechanical equipment, motors are responsible for promoting the important mission of productivity enhancement. 6kV high-voltage motors, with their high efficiency, stability and energy-saving characteristics, have gradually become an indispensable core equipment in large-scale machinery, mining, metallurgical industry and power system. They not only provide strong and continuous power, but also show extraordinary durability and reliability in complex working environments.

🚀 Core strengths and technological innovation

The advantages of choosing 6kV high voltage motors are mainly reflected in the following aspects:

- High efficiency drive, energy saving and emission reduction: Compared with low-voltage motors, 6kV high-voltage motors are able to reduce current losses due to their high-voltage operating principle, thus significantly improving energy efficiency. Reduced energy consumption not only reduces the operating costs of the enterprise, but also conforms to the current green industrial development concept.

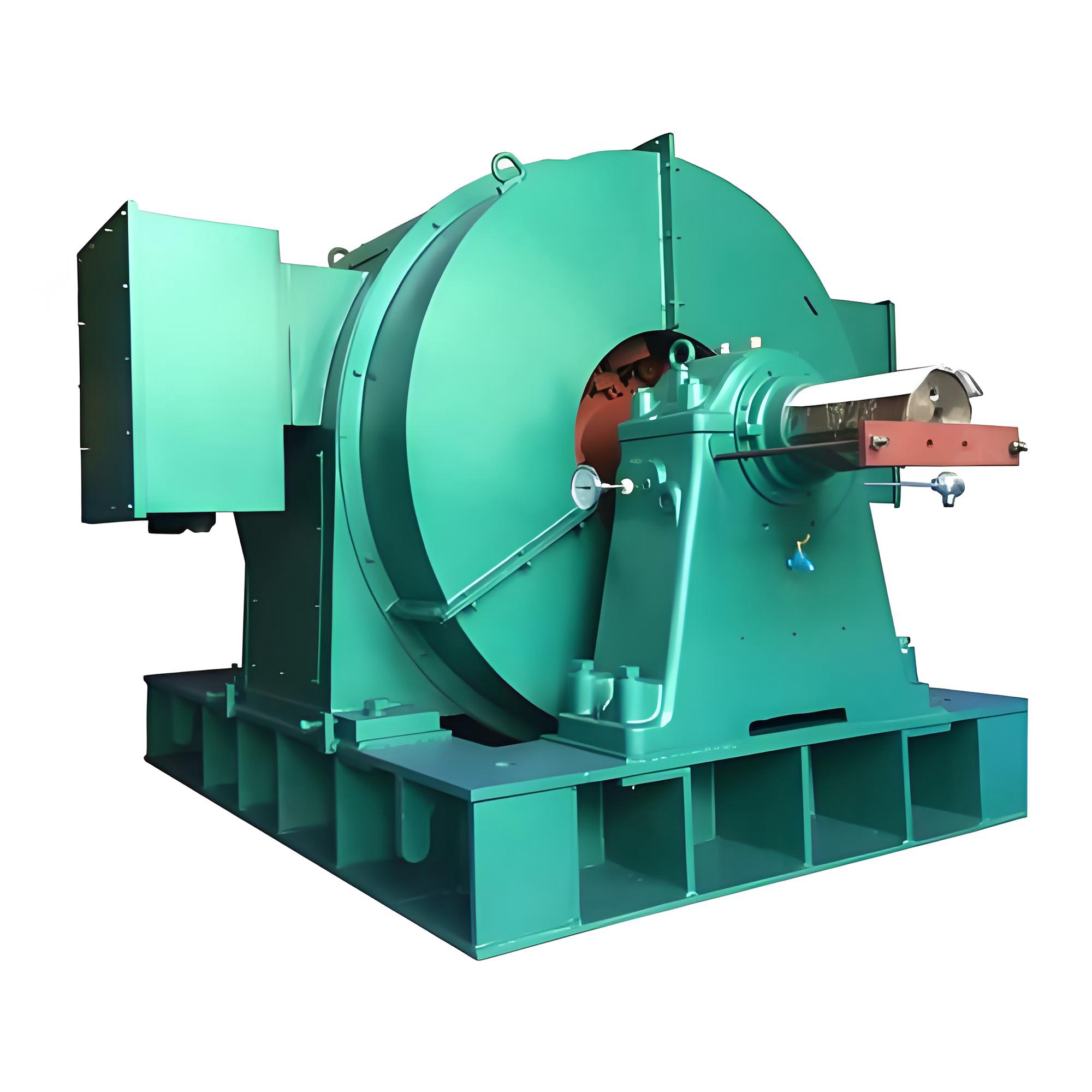

- Stronger load capacity: High voltage motorsWith larger capacity and stronger torque output capability, it is suitable for large mechanical equipment, such as mining trucks, thermal power generators, steel rolling mills, etc. Its superior performance ensures the smooth operation of the production line and improves the overall production efficiency.

- Robust structure and stable operation: 6kV high-voltage motors are usually made of heat- and corrosion-resistant materials, together with advanced manufacturing processes, to ensure stable operation even in harsh environments such as high temperature, high humidity and dust. This is especially important for industrial applications that require continuous operation and high reliability.

- Highly customizable: With the development of industrial automation and intelligent manufacturing, 6kV high-voltage motors can be customized according to different process requirements, such as adjusting the speed, torque, insulation level, etc. to match various special application scenarios.

🏭 Wide range of applications

6kV high voltage motors play an important role in several industries:

- Metallurgy and Mining: In steel mills, the power systems of heavy rolling mills and steel furnaces are mostly powered by 6kV high voltage motors to ensure the continuity and efficiency of the production process. In mining, high-voltage motor-driven mine cars and winches, undertake heavy-duty operations.

- Power Systems: Power station generators, fans, pumps, etc. rely on these high-voltage motors for efficient drives.

- Other industries: It is also widely used in many industries such as chemical, paper, and machinery manufacturing.

🛣️ Future Trends and Selection/Maintenance Guide

Future Development Trend: Intelligent and Energy Saving

- Intelligent development: Through the introduction of sensors and IoT technology, the operating status of the motor can be monitored in real time, early warning of potential failures, reducing maintenance costs and extending equipment life.

- New material applications: The application of new materials and new technology makes the insulation and temperature resistance of high-voltage motors continuously enhanced to adapt to more severe working environments.

Selection and Maintenance Recommendations

- Selection Guide:

- Define the load requirements: The first step is to define the load rating for the actual application, including torque, speed, and continuous running time.

- Focus on core parameters: Attention is paid to insulation level, protection level (e.g. IP rating), efficiency level, etc., to ensure that they can meet the special requirements of industrial environments.

- Maintenance management:

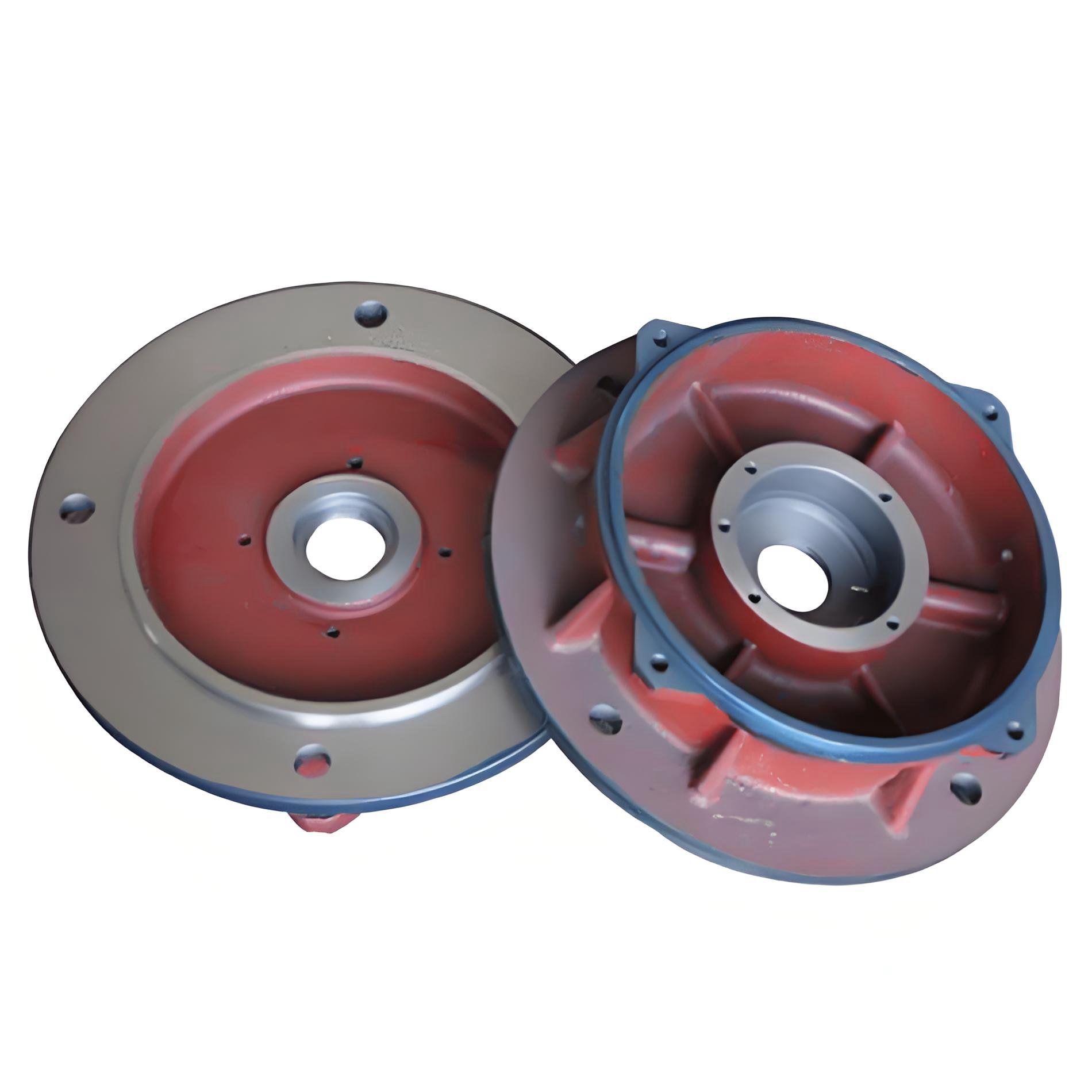

- Regular inspections: Check that the motor terminals, insulation, and cooling system are intact.

- Maintenance lubrication: Replace or add lubricant regularly to ensure smooth bearing operation.

- Insulation Protection: Measure the insulation resistance value periodically to test the insulation performance and prevent leakage accidents.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206