Direct sales from professional motor manufacturers, offering exceptional quality and supporting customization in multiple specifications.

Date: 2025-12-16 Categories: Faq Views: 3112

Excerpt:

Looking for high-quality motor manufacturers? Uncover the core factors determining equipment performance. In today's era of rapid industrial automation advancement, motors are hailed as the “heart of industry,” with their performance directly dictating the operational efficiency and stability of end-use equipment. For procurement professionals and engineers navigating a vast array of suppliers in the market, the challenge lies in how to stand out from the crowd.

Article Catalog[Hidden]

Seeking high-qualityMotor ManufacturerUnveiling the Core Factors That Determine Equipment Performance

In today's era of rapid advancement in modern industrial automation, electric motors are hailed as the “heart of industry,” with their performance directly determining the operational efficiency and stability of end-use equipment. For procurement personnel and engineers, faced with a vast array of suppliers in the market, the challenge lies in how to select from the multitude of options.Motor ManufacturerSelecting partners with genuine core competitiveness is often a challenging task. Choosing the right manufacturer not only enhances product quality but also effectively reduces long-term maintenance costs; conversely, the wrong choice may lead to frequent downtime and significant energy waste.

R&D Capabilities: Beyond Manufacturing, Innovation Takes Center Stage

An excellentMotor ManufacturerIt is by no means a simple assembly plant, but rather a research and development center with deep technical expertise. When evaluating manufacturers, the first consideration should be whether they possessIndependent design and R&D teamWith the implementation of energy conservation and emission reduction policies,Energy efficient motorshas become the mainstream in the market.

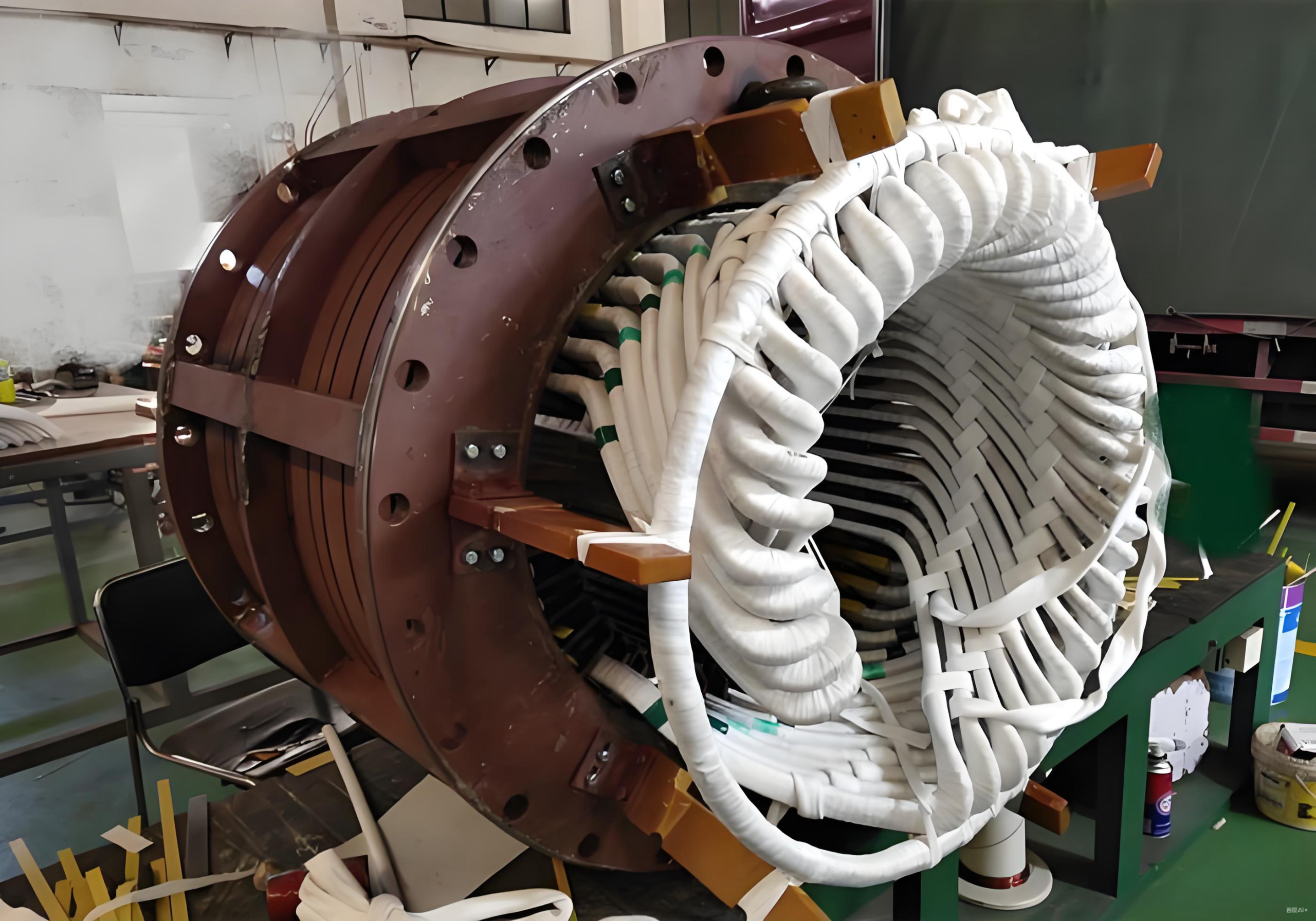

Manufacturers with independent R&D capabilitiesWe can optimize electromagnetic designs based on customers' specific operating conditions. For instance, by improving stator and rotor slot profiles or optimizing winding configurations, we enhance motor power density and efficiency. Companies that merely produce generic standard products without offering tailored technical improvements often struggle to meet the demands of high-end equipment.

Precision manufacturing processes and quality control

![[Keywords] [Keywords]](https://simo.org.cn/wp-content/uploads/2025/11/1763984461-22111.png)

Motor manufacturing is a complex process involving multiple fields such as machining, electromagnetics, and insulation treatment.Precision of manufacturing processesDirectly affects the motor's noise, vibration, and lifespan. High-qualityMotor ManufacturerAutomated production lines are typically introduced to minimize human error.

For example, in the critical “vacuum impregnation” process, professional manufacturers will employVPI Vacuum Pressure Impregnation ProcessEnsure that the insulating varnish fully penetrates the interior of the windings, thereby significantly enhancing the motor's insulation performance and heat dissipation capabilities. Additionally, strictQuality Inspection SystemIt is also indispensable. From the iron loss testing of silicon steel sheets upon arrival at the factory to the full-performance load testing before shipment, every piece of data throughout the entire process must be traceable.

Case Study: Demonstrating Customization Capabilities for Non-Standard Products

To better understand the importance of selecting the right manufacturer, consider this real-world example. When developing a new high-speed loom, a major textile machinery company encountered insufficient starting torque from standard motors. This resulted in slow equipment startup, negatively impacting production cycle times.

The company contacted several suppliers and ultimately selected one specializing inManufacturer of Industrial Specialty MotorsThe manufacturer did not directly promote stock products but instead dispatched a technical team to conduct on-site analysis of load characteristics. By adjusting the shape of the rotor conductors and utilizing specialized alloy materials, the manufacturer provided the textile enterprise with a customized solution.Non-standard Custom MotorsThe results show that the new motor's starting torque increased by 301 N·m, while temperature rise remained within acceptable limits, perfectly addressing the customer's pain points. This case clearly demonstrates that the motor possessesFlexible customization capabilitiesis a measure of modernizationelectric motor factoryAn important criterion for a home.

Perfect after-sales service system

The lifecycle of industrial equipment typically spans several years or even decades, therefore,Motor ManufacturerService awareness is equally crucial. Beyond the promised warranty period, key considerations include the manufacturer's response speed to malfunctions, the timeliness of spare parts supply, and whether remote technical support is provided. Premium manufacturers extend their service to the pre-sales stage, assisting customers with model selection calculations to avoid energy waste caused by “overkill” and truly maximize value throughout the entire lifecycle.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206