Energy efficient 6kv high voltage motor model parameters and application selection guide

Date: 2025-12-25 Categories: Company News Views: 4162

Excerpt:

6kv High Voltage Motors: Efficient Drive Solutions for Heavy Industry In the grand narrative of modern heavy industry, the drive system is as vital as the heart. When the production line is faced with high-power load demand, ordinary low-voltage motors are often overstretched, not only the current is too large, resulting in a surge in line loss, and it is more difficult to ensure the stability of system operation. At this time, 6

Article Catalog[Hidden]

6kvHigh voltage motors: Efficient Drive Solutions for Heavy Industry

In the grand narrative of modern heavy industry, the drive system is as vital as the heart. When the production line is faced with high-power load demand, ordinary low-voltage motors are often overstretched, not only the current is too large, resulting in a surge in line loss, but also difficult to ensure the stability of the system operation. At this time, the6kv high voltage motorWith its excellent energy efficiency and strong torque output, it has become the preferred power source for mining, petrochemical, electric power and metallurgy. This is not just a choice of equipment, but also a deep consideration of long-term operating costs and productivity.

Why did you choose the 6kv voltage level?

Compared to 380V or 660V low voltage equipment, the6kv high voltage motorThe core advantage lies in its physical characteristics of “high voltage and low current”. According to the power equation

This characteristic brings significant economic benefits:

- Significant reduction in line losses: The reduced current directly reduces the heat losses in the stator windings and the transmission cable (

I²R ), which improves the overall system power utilization. - Infrastructure cost optimization: Due to the lower current, the distribution system can use cables with a smaller cross-sectional area, which can save considerable material costs in wiring projects for large-span plants.

Structural advantages and technical features

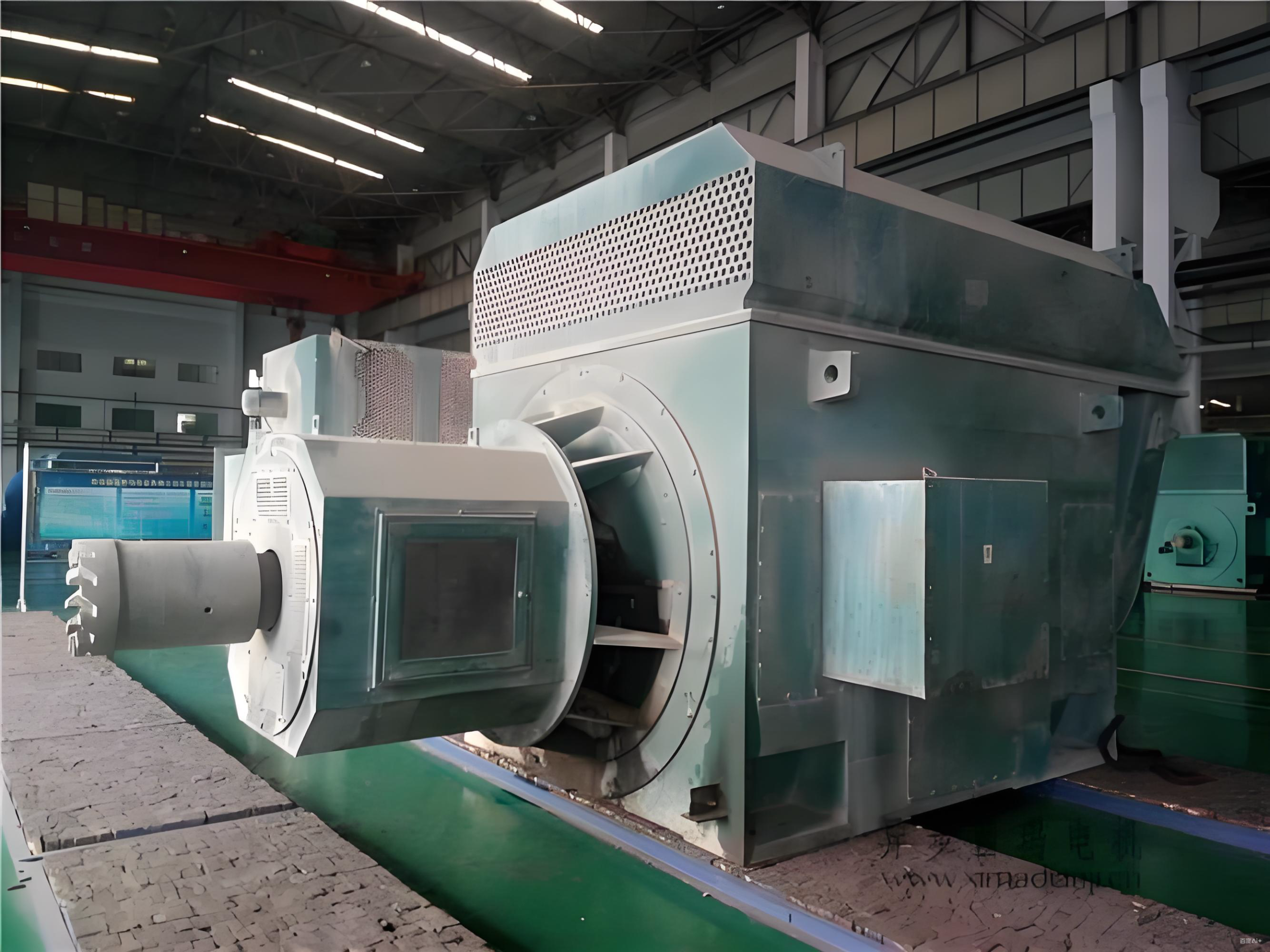

quality6kv high voltage motorThey are usually of high-strength box-type construction, compact in design and light in weight. In order to cope with corona corrosion in high-voltage environments, the stator windings are usually insulated to a level ofClass F or Hand treated with the Vacuum Pressure Impregnation (VPI) process.

- Insulation Reliability: The VPI process ensures that there is no air gap in the winding insulation, which greatly improves the motor's resistance to moisture, dust and corrosion, enabling it to adapt to harsh industrial environments.

- cooling systemAccording to different working conditions, users can choose various cooling methods, such as IC01, IC611 or IC81W, to ensure that the temperature rise of the motor is controlled within a reasonable range during full-load operation and to prolong the life of the equipment.

Application Case Study: Cement Plant Fan Retrofit

Take the high-temperature fan retrofit project of a large cement plant as an example. The plant originally used an old low voltage drive system with high failure rate and alarming energy consumption. In the technical reform program, the engineering team introduced a 1250kW rated power6kv high voltage motor(YKK series).

![[Keywords] [Keywords]](https://simo.org.cn/wp-content/uploads/2025/11/1763984466-25662.png)

The results of the remodeling were immediate:

- Startup Performance ImprovementThe starting process of the turbine is smoother and the impact on the grid is significantly reduced thanks to the excellent starting torque of the high-voltage motor.

- Energy-saving data: After six months of continuous monitoring, under the same air volume output, the system's comprehensive power saving rate reaches12%This is mainly due to the improved efficiency of the motor body and the reduction of line losses. This is mainly attributed to the improvement of the efficiency of the motor body and the reduction of line losses, and it is expected that the investment cost of the equipment can be recovered within 1.5 years.

Key Considerations for Selection and Maintenance

When selecting6kv high voltage motorWhen you choose a torque curve, you should not only pay attention to the power and speed, but also choose a suitable torque curve in combination with the load characteristics (e.g., pump loads or crusher loads).

Routine maintenance should likewise not be neglected. Due to the high voltage level, thePeriodic testing of insulation resistance和absorption ratioIt is the core of preventive maintenance. It is recommended that enterprises introduce online vibration monitoring system, real-time monitoring of the status of bearings, to prevent damage to the insulation structure due to excessive mechanical vibration, so as to ensure that the industrial “artery” is always strong and powerful beat.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206