Xima Railway Dedicated Motors: High Efficiency and Durability, Supporting Safe Operation of Rail Transit

Date: 2025-12-08 Categories: Industry News Views: 9307

Excerpt:

Xima Railway Dedicated Motors: The Core Power Solution Behind Rail Transit In today's era of rapid rail transit development, every smooth start and safe journey of a train relies on the powerful “heart” hidden within its body. For railway transportation, motors are not only the source of power but also the lifeline of operational safety. Confronting extreme temperature fluctuations, continuous vibrations, and complex

Article Catalog[Hidden]

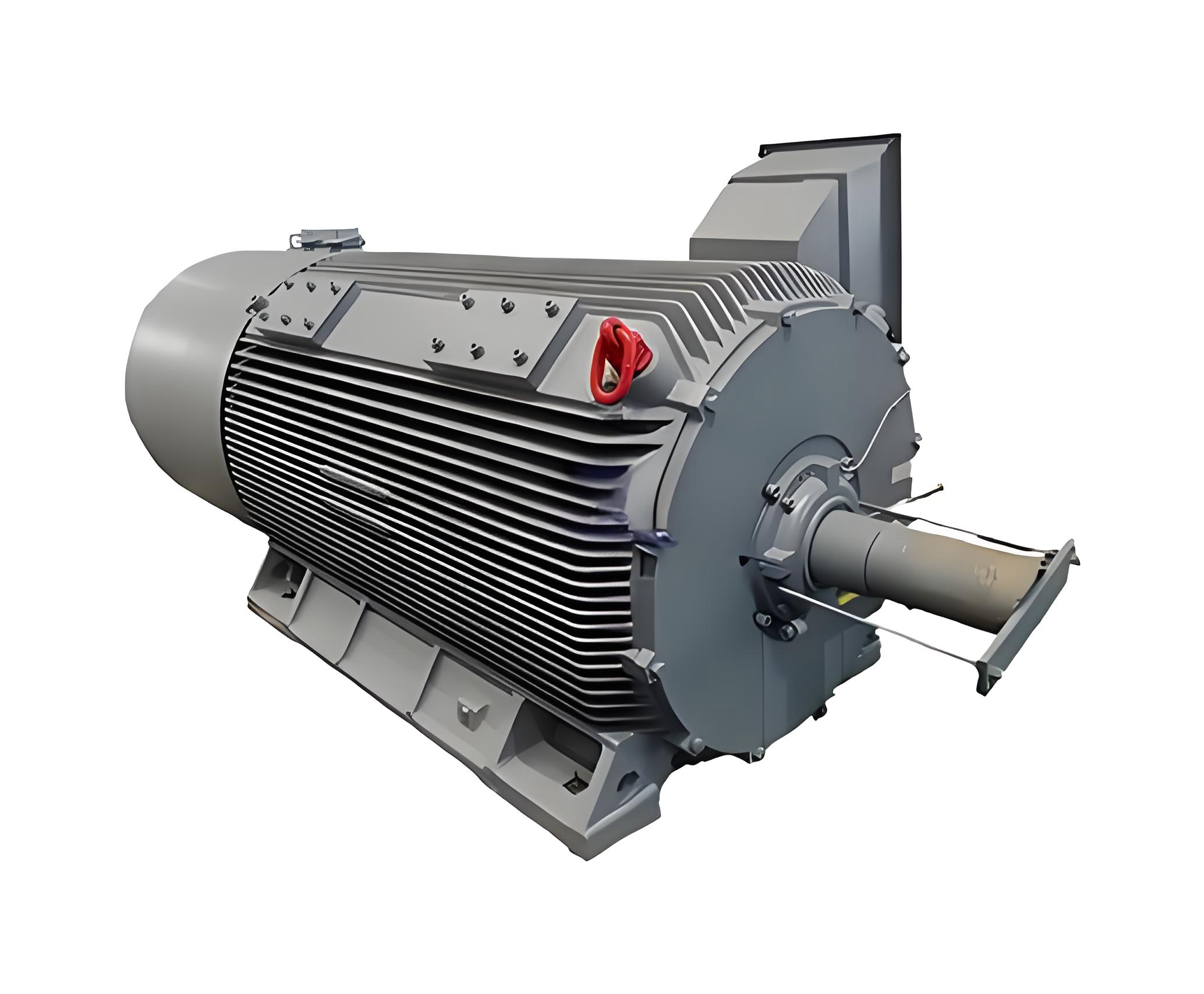

Simo Railway MotorsHardcore Power Solutions Behind Rail Transit

In today's era of rapid development in modern rail transit, every smooth start and safe journey of a train relies on the powerful “heart” hidden deep within its body. For railway transportation, electric motors are not only the source of power but also the lifeline of operational safety. Confronted with extreme temperature fluctuations, continuous vibrations, and complex electromagnetic environments, ordinary industrial motors often fall short. It is precisely under these demanding requirements that...Simo Railway MotorsWith its exceptional durability and technological expertise, it has become the preferred choice for numerous railway engineering and locomotive maintenance projects, quietly supporting the stable operation of everything from heavy freight transport to track maintenance vehicles.

Technical DNA: Born for Demanding Environments

Simo Railway MotorsThe core reason for its strong market position lies in its deeply customized design tailored for railway operating conditions. Unlike standard motors, railway motors must withstand frequent starts, stops, and sudden load changes. In its design, Xima employs...Special Insulation SystemsTypically meeting Class H or higher standards, this ensures the motor maintains stable electrical performance under high temperatures and heavy loads, effectively preventing short-circuit failures caused by insulation aging.

Additionally, considering the unavoidable vibration issues associated with railway lines,Simo motorsMechanical structural modifications have been implemented.Reinforced processingBy optimizing bearing configuration and enhancing frame rigidity, the motor ensures no shaft misalignment occurs during prolonged severe vibration, significantly extending equipment service life.

Diverse Applications: Full Coverage from Towing to Assistance

Within the railway system, the demand for power is multi-tiered.Simo Railway MotorsThe product line encompasses DC traction motors, ACVariable Frequency Drive Motorand various auxiliary motors.

- Traction powerFor industrial and mining locomotives as well as engineering work vehicles, Xima provides DC traction motors featuringHigh starting torqueIts characteristics enable it to deliver instantaneous bursts of power under heavy loads, ensuring trains can climb inclines or start moving smoothly.

- Auxiliary SystemIn the train's ventilation and cooling systems, air compressor drives, and oil pump systems, Xima's auxiliary motors demonstrate exceptionally high energy efficiency ratios. Despite their compact size, these motors demand extremely high continuous operational reliability to ensure the proper circulation of the train's “lungs” and “bloodstream” systems.

Case Study: Power Upgrade for a Dedicated Railway Logistics Line in Northwest China

To gain a more intuitive understandingSimo Railway MotorsTo assess its actual effectiveness, we can refer to the railway spur line renovation project undertaken by a major energy company in Northwest China. Located in a Gobi region characterized by high winds, sandstorms, and extreme temperature fluctuations, the line's aging electric motors suffered frequent failures due to inadequate sealing and heat dissipation issues, severely impacting coal transportation efficiency.

During the technical upgrade, the engineering team selected Xima's optimized solution for sandstorm environments.Fully Enclosed Air-Cooled Railway-Specific MotorThis motor employs a uniqueLabyrinth Seal StructureEffectively blocks fine dust particles from entering the motor interior. After one year of operational monitoring, data shows:

- The failure rate of motor insulation due to dust has been reduced to zero.

- Under extreme operating conditions where surface temperatures exceed 50°C in summer, the motor temperature rise remains within safe limits.

- Overall maintenance costs decreased by approximately 40% compared to pre-renovation levels.

This case clearly demonstrates that selecting high-quality motors tailored to specific operating conditions is a critical factor in ensuring the smooth flow of railway logistics.

Smart Manufacturing Sets the Quality Benchmark

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2023/08/1763949810-100252.jpg)

In addition to its design advantages,Simo motorsIn manufacturing processes, intelligent inspection methods are continuously integrated. Every railway-specific motor leaving the factory undergoes load testing and vibration experiments simulating real-world operating conditions. This near-obsessive quality control ensures products delivered to customers achieve “plug-and-play functionality with long-term reliability.” For railway bureaus and industrial enterprises pursuing efficient operations, Xima is not merely an equipment supplier but a trusted technical partner for rail transit power systems.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206