Detailed Parameters of High-Efficiency Energy-Saving 6kV High-Voltage Motors and Latest Manufacturer Pricing

Date: 2025-12-08 Categories: Company News Views: 7191

Excerpt:

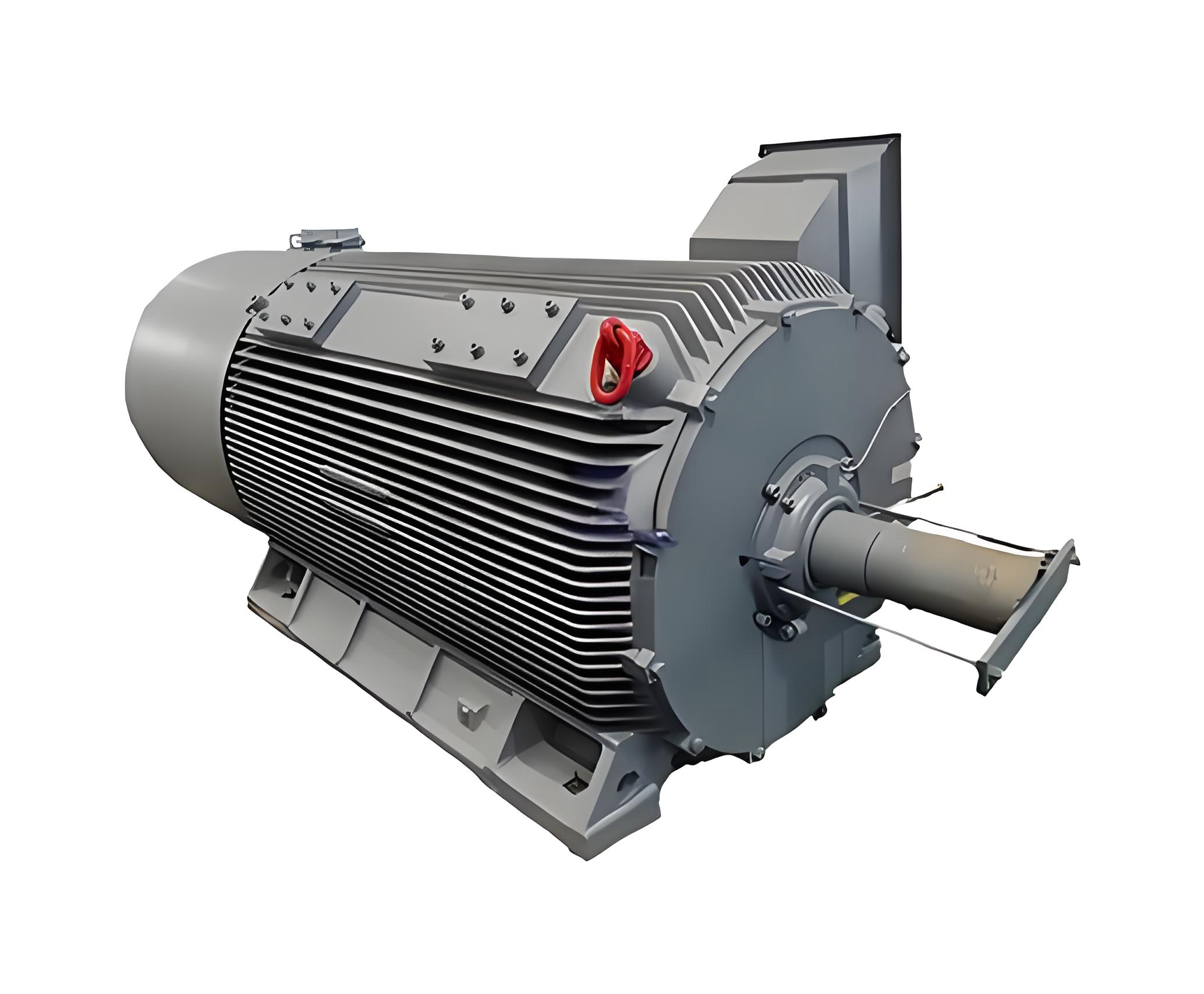

In-Depth Analysis of 6kV High-Voltage Motors: The Key Driver for Industrial Efficiency Enhancement In modern heavy industry, as production scales expand and equipment power demands rise, conventional low-voltage motors struggle to meet the drive requirements of high-power loads. Here, 6kV high-voltage motors emerge as the optimal choice bridging low-voltage and ultra-high-voltage systems, leveraging their unique voltage-level advantages and exceptional energy efficiency. For those pursuing high efficiency and low losses,

Article Catalog[Hidden]

In-depth Analysis6kV high voltage motorThe Key Drivers of Industrial Efficiency Enhancement

In the modern heavy industry sector, as production scales expand and equipment power demands increase, conventional low-voltage motors struggle to meet the drive requirements of high-power loads. At this point,6kV high voltage motorWith its unique voltage-level advantages and outstanding energy efficiency performance, it has become the golden choice for bridging low-voltage and ultra-high-voltage systems. For enterprises pursuing high efficiency and low losses, gaining a deep understanding of the operational mechanisms and selection strategies of this industrial “heart” is a crucial step toward achieving energy savings, reducing consumption, and optimizing production costs.

Why choose the 6kV voltage level?

Compared to low-voltage motors operating at 380V or 660V,6kV high voltage motorThe core advantage lies in “high voltage, low current.” According to the laws of physics, at the same output power, the higher the voltage, the lower the current. This characteristic directly delivers the following significant benefits:

- Reduce line lossesThe reduction in current significantly decreased the stator copper losses.

I²R ), thereby enhancing the overall operational efficiency of the motor. - Reduce cable costsLower current requirements enable the use of cables with smaller cross-sectional areas for power transmission, significantly reducing infrastructure investment in distribution systems.

- Superior startup performanceAlthough the starting torque is relatively high, it can be managed by coordinating withSoft-start deviceor variable frequency drive,6kV high voltage motorCapable of maintaining smooth startup under high inertia loads, minimizing impact on the power grid.

Core Application Scenarios and Technical Features

6kV high voltage motorWidely used in the power, mining, metallurgical, chemical, and water conservancy industries, primarily for driving various general-purpose machinery such as compressors, water pumps, crushers, cutting machine tools, transport machinery, and other mechanical equipment.

On the technical level, high-quality6kV motoris commonly usedClass F or Class H insulationThe system incorporates vacuum pressure impregnation (VPI) technology. This process not only enhances the electrical and mechanical strength of the windings but also endows the motor with exceptional resistance to moisture, dust, and corrosion.Especially in harsh industrial and mining environments, this high-standard insulation treatment ensures the long-term stable operation of equipment.

Selection and Maintenance: Insights from Frontline Cases

Enterprises in procurement and deployment6kV high voltage motorWhen selecting equipment, one must not focus solely on rated power; instead, comprehensive consideration should be given to protection ratings, cooling methods, and energy efficiency standards.

Taking the water circulation system retrofit at a large chemical plant as an example, the facility originally employed multiple outdated, high-energy-consumption motors to drive its circulation pumps. During the technical upgrade, the engineering team selected high-efficiencyYX3 Series 6kV High-Voltage MotorsDuring the selection process, the team focused on the following two points:

- Load MatchingEnsure the motor power factor approaches 1.0 to avoid reactive power losses caused by over-sizing the motor for the load.

- Cooling methodFor high-temperature environments in chemical plants, the IC411 (fully enclosed fan-cooled) structure was selected to ensure efficient heat dissipation.

Following the retrofit, data indicates that the system achieved an overall energy savings rate exceeding 12%. Furthermore, due to the advanced bearing design of the new motors, equipment maintenance intervals have been extended from quarterly to biannual.

Key Considerations

Although6kV high voltage motorThe advantages are evident, but attention to detail is still required during actual operation. Due to the high voltage levels, strict requirements are imposed on the qualifications of operators and adherence to safety protocols. Additionally,Periodic insulation resistance testing和Bearing Temperature MonitoringIt is an indispensable measure for preventing failures. In variable-frequency speed control scenarios, special attention must be paid to the motor insulation structure's tolerance for high-frequency harmonics. Where necessary, dedicated variable-frequency motors should be selected.

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2025/11/1764027776-6788.jpg)

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206