Xi'an TaiFu Xima Electric Motor Official Factory Direct Sales Complete Model Range with Competitive Pricing

Date: 2025-12-10 Categories: Faq Views: 4740

Excerpt:

Powering the Heart of Industry: A Deep Dive into TaiFu Xima Motor's Core Competitive Edge Amidst the roar of modern industrial operations, electric motors are hailed as the “heart” of machinery. Whether driving precision manufacturing lines or massive conveyor belts deep within mines, the stability of power directly determines a company's production efficiency and operational costs. Among numerous power solution providers, TaiFu Xima Motor stands out through its profound technological expertise...

Article Catalog[Hidden]

Powering the Industrial Heart: An In-Depth AnalysisTaifu Simo MotorCore Competitive Advantage

Amidst the roaring rhythm of modern industry, electric motors are hailed as the “heart” of machinery. Whether powering precision manufacturing lines or massive conveyor belts deep within mines, the stability of this driving force directly determines a company's production efficiency and operational costs. Among numerous power solution providers,Taifu Simo MotorWith its deep technical expertise and exceptional adaptability to diverse operating conditions, it has become the preferred choice for numerous industry leaders. How does one break through the complex motor market with “technology” and “energy efficiency”? Today, we delve into the core strengths behind this benchmark in industrial power.

Heritage and Innovation: More Than Just Manufacturing

When mentioningTaifu Simo MotorIndustry insiders immediately associate it with its origins inXi'an Simo MotorPure lineage. This represents not only decades of motor manufacturing expertise, but also signifies a commitment toQuality StandardsThe rigorous adherence. Unlike ordinaryelectric motor factoryThrough simple assembly, Taifu Xima incorporated advanced electromagnetic design principles during the R&D phase, ensuring every unit maintains outstanding electrical performance even under full load conditions.

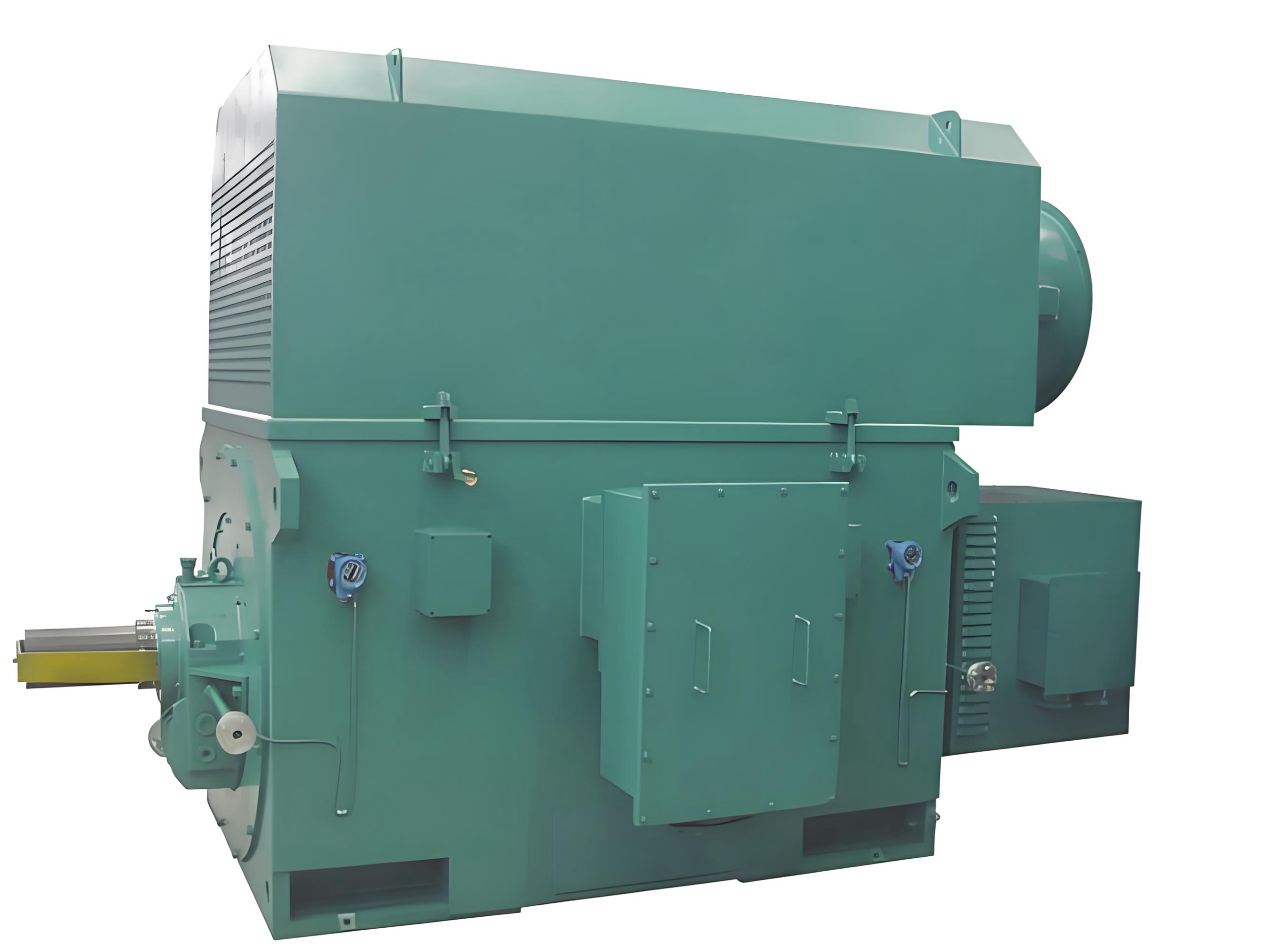

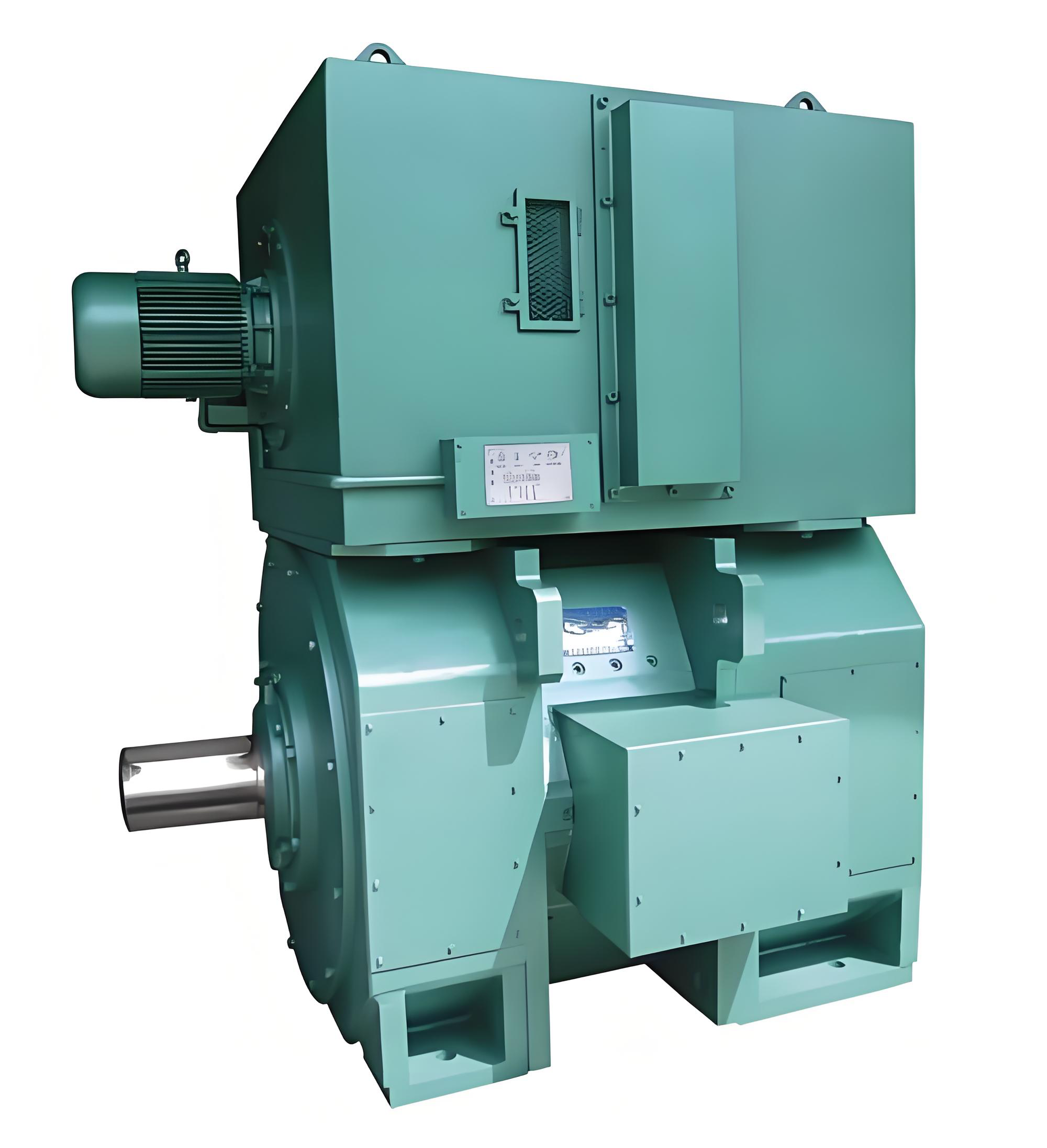

Its core strength lies inHigh voltage motors与DC motorDeep customization capabilities. For specialized industries such as petroleum, chemical processing, and metallurgy, standard products often fail to meet complex operational demands. Through optimizing stator and rotor laminations and insulation systems, Taifu Xima significantly enhances motor overload capacity and heat dissipation efficiency. This “tailor-made” manufacturing approach has secured its prominent position in the high-end equipment supply sector.

Energy Efficiency Revolution: The Key to Cost Reduction and Efficiency Enhancement

Against the backdrop of the “dual carbon” goals, enterprises are placing unprecedented demands on the energy efficiency ratios of their equipment.Taifu Simo MotorQuickly recognizing this market trend, the company vigorously promoted its high-efficiency, energy-saving products. With its YE4 series ultra-high-efficiencythree-phase asynchronous motorFor example, this product series achieves industry-leading operational efficiency through the use of low-loss cold-rolled silicon steel sheets and precision manufacturing processes.

For a manufacturing enterprise with massive annual electricity consumption, replacing outdated, high-energy-consumption motors withTaifu Xima High-Efficiency MotorsAlthough initial investment has increased, the *lifecycle cost (LCC)* has significantly decreased. This “big-picture” return on investment represents the core value that lean management enterprises prioritize.

Case Study: Stability Validation in Harsh Environments

To gain a more intuitive understandingTaifu Simo MotorTo demonstrate its reliability, we can refer to the retrofit case of a rolling mill production line at a major steel group. The original motors on this line frequently experienced insulation aging and bearing failures due to prolonged exposure to high temperatures and dusty environments, resulting in persistently high levels of unplanned downtime.

In introducing the technology developed by Taifu Xima,Z4 Series DC MotorsFollowing these measures, the situation underwent a fundamental reversal. The motor series specifically enhanced its protection rating and adopted a specialized VPI (Vacuum Pressure Impregnation) process, significantly boosting the coil's resistance to moisture, dust, and corrosion. After 12 consecutive months of intensive operational monitoring, the failure rate decreased by nearly 95%, not only ensuring production continuity but also substantially reducing the maintenance team's workload. This case study fully demonstrates that:A good motor is one that can withstand the rigors of harsh operating conditions.

Service Network and Technical Support

Beyond the rock-solid product quality,Taifu Simo MotorAnother key advantage in the market is its responsive technical service system.Selecting industrial motors often involves complex parameter matching—from power and speed to mounting configurations. Any oversight in these details can lead to operational risks down the line. By establishing comprehensive pre-sales technical consultation and post-sales rapid response mechanisms, Taifu Xima ensures customers receive not just a cold machine, but a complete power assurance solution. This end-to-end service loop further solidifies its brand moat as a premium motor supplier.

![[Keywords] [Keywords]](https://simo.org.cn/wp-content/uploads/2023/08/1764156856-3822.jpg)

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206