Professional Xima Motor Repair, Maintenance, and Fault Diagnosis One-Stop Service

Date: 2025-12-10 Categories: Industry News Views: 1830

Excerpt:

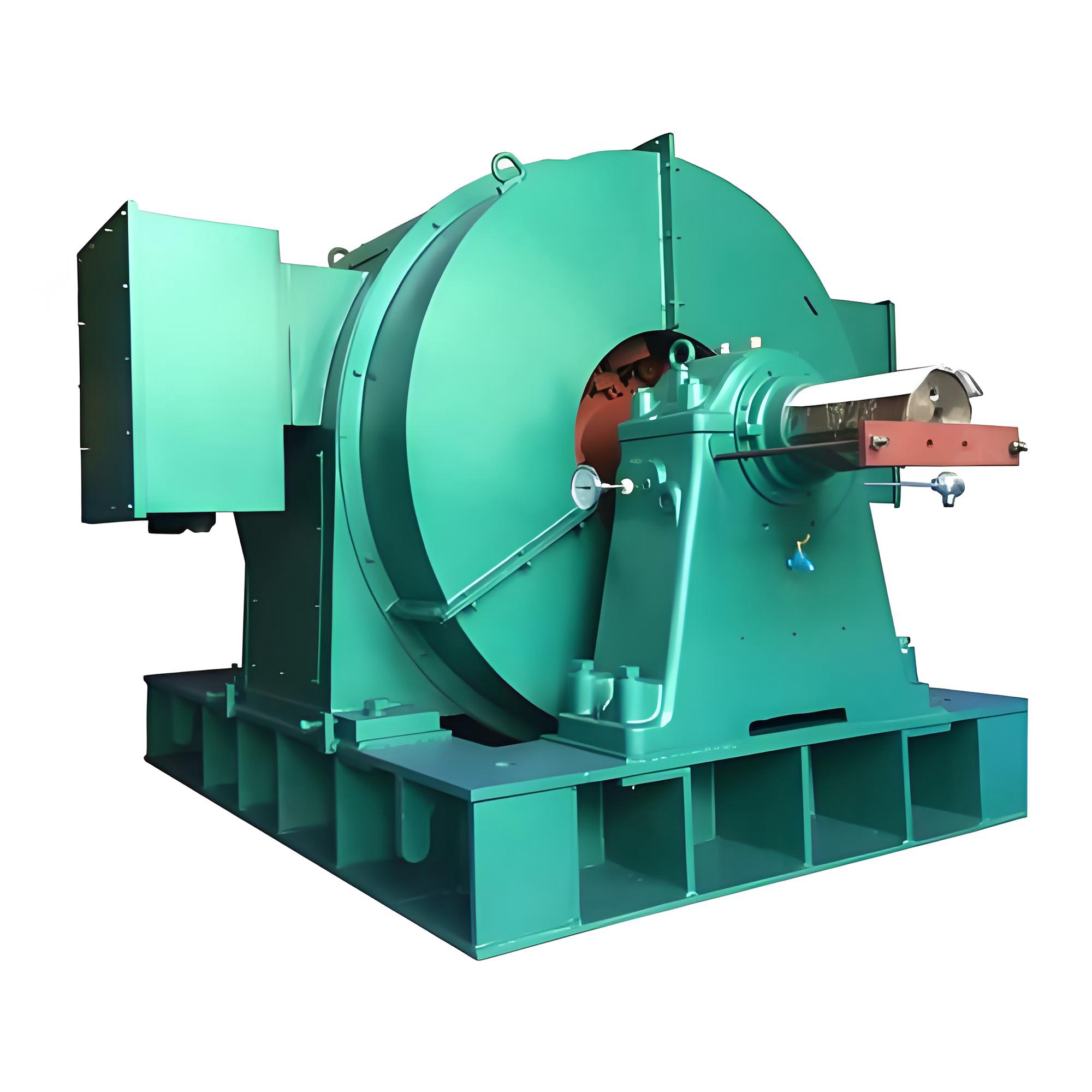

In-Depth Analysis of Simo Motor Maintenance: Key Technologies and Practical Case Studies At the heart of industrial production, Simo motors are widely utilized in core sectors such as power generation, metallurgy, and petrochemicals due to their exceptional performance and reliability. However, even the most advanced industrial equipment experiences wear and tear under prolonged full-load operation.

Article Catalog[Hidden]

In-depth AnalysisSimo motorsMaintenance: Key Technologies and Practical Case Studies

At the heart of industrial production, Simo Motors are widely utilized in core sectors such as power generation, metallurgy, and petrochemicals due to their exceptional performance and reliability. However, even the most advanced industrial equipment inevitably experiences wear or malfunctions after prolonged full-load operation. At such times, professional and preciseSima Motor RepairService is not merely an emergency measure to resume production; it is a critical factor in extending equipment lifespan and reducing operational costs. This article will delve into common failure types of Xima motors and their repair techniques, helping you quickly pinpoint issues and implement effective solutions.

I. Precise Diagnosis of Common Faults

carry outSima Motor RepairThe first step is always scientific fault diagnosis. Unlike ordinary motors, Xima motors (especially high-voltage and DC series) are highly sensitive to operating environment parameters. Maintenance personnel typically focus on the following three core indicators:

- Abnormal Vibration and NoiseThis is often a precursor to mechanical failure. It may be due toBearing wearCaused by rotor dynamic imbalance failure or frame loosening. For large-scaleHigh voltage motorsEven a slight knocking sound may indicate uneven air gaps, requiring immediate shutdown for inspection.

- Excessive temperature riseWhen the temperature of motor windings exceeds the permissible range for the insulation class (e.g., exceeding 155°C for F-class insulation), this typically indicates a blocked cooling system, overload operation, or interturn short circuit.

- Insulation resistance decreaseWhen testing with a megohmmeter, if a sharp drop in insulation resistance is detected, it is typically caused by moisture ingress or insulation aging. Drying treatment or coil rewinding must be performed.

II. Core Repair Process Flow

High-qualitySima Motor RepairIt is by no means a simple replacement of parts, but rather a meticulously designed system engineering project.

- Stator Winding Rewinding and Insulation TreatmentThis is akin to open-heart surgery in motor repair. After removing the old windings, the slots must be cleaned, and high-grade electromagnetic wire must be selected for rewinding. The key lies in adoptingVPI Vacuum Pressure Impregnation ProcessEnsure that the insulating varnish penetrates every void in the windings, thereby significantly enhancing the motor's insulation strength and moisture resistance.

- Rotor Dynamic Balancing CorrectionTo eliminate centrifugal forces during rotation, repaired rotors must undergo verification on a dynamic balancing machine. For Xima motors operating above 1500 rpm, high-precision dynamic balancing is essential to prevent secondary vibrations.

- Commutator RepairFor the Xima Z4 SeriesDC motorThe surface finish of the commutator directly affects spark levels. During maintenance, precision turning and undercutting of the mica between segments must be performed to ensure perfect concentricity of the carbon brush contact surfaces.

III. Practical Case Analysis: Excessive Sparking in Z4 DC Motor

On the rolling mill production line of a large steel mill, a Z4-400 modelSimo DC MotorDuring operation, excessive sparks (reaching Level 3) were observed at the brush holder, accompanied by a burning odor, causing frequent circuit breaker trips on the production line.

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2025/11/1764033560-34342.jpg)

Repair Process Analysis:

After the maintenance team intervened, they first inspected the carbon brushes and found uneven wear along with spring pressure imbalance. Further disassembly revealed distinct “burn grooves” on the commutator surface caused by prolonged electrical spark corrosion.

- surface treatmentThe technician performed precision turning on the commutator, removing the oxide film and burn marks.

- Mica EngravingRe-engrave and chamfer the mica sheets between segments to prevent protruding mica from scratching the carbon brushes.

- Neutral Surface AdjustmentThis isSima Motor RepairThe technical challenges involved. The technicians recalibrated the equipment.brush holderPosition it to ensure it is on the geometric neutral line.

Following the above measures, the motor was recommissioned with spark levels controlled below 1.25, maintaining stable rotational speed and completely eliminating the risk of shutdown.

IV. Preventive Maintenance Strategy

To minimize unexpected failures, establishing a periodic maintenance schedule is crucial. It is recommended that enterprises conduct quarterly inspections of their motors.Bearing GreaseConduct sampling analysis and promptly replenish or replace high-temperature grease. Simultaneously, regularly inspect the motor's electrical parameters and record trends in insulation resistance. Professional maintenance not only fundamentally reducesSima Motor RepairThe frequency of maintenance not only ensures the continuity and efficiency of industrial production lines.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206