Xi'an Xima JS Series Three-Phase Asynchronous Motor Models, Parameters, and Pricing Explained

Date: 2025-12-08 Categories: Company News Views: 3822

Excerpt:

Driving the Core of Industrial Power: An In-Depth Analysis of the High Efficiency and Application Value of Xima JS Motors In the grand narrative of modern industrial production, motors serve as the “heart” of mechanical equipment. Their performance directly determines the operational efficiency and energy consumption costs of entire production lines. Facing increasingly stringent environmental standards and the pursuit of maximum production capacity,

Article Catalog[Hidden]

Driving the Core of Industrial Power: An In-Depth Analysis of the High Efficiency and Application Value of the Xima JS Motor

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2025/11/1764032936-90820.jpg)

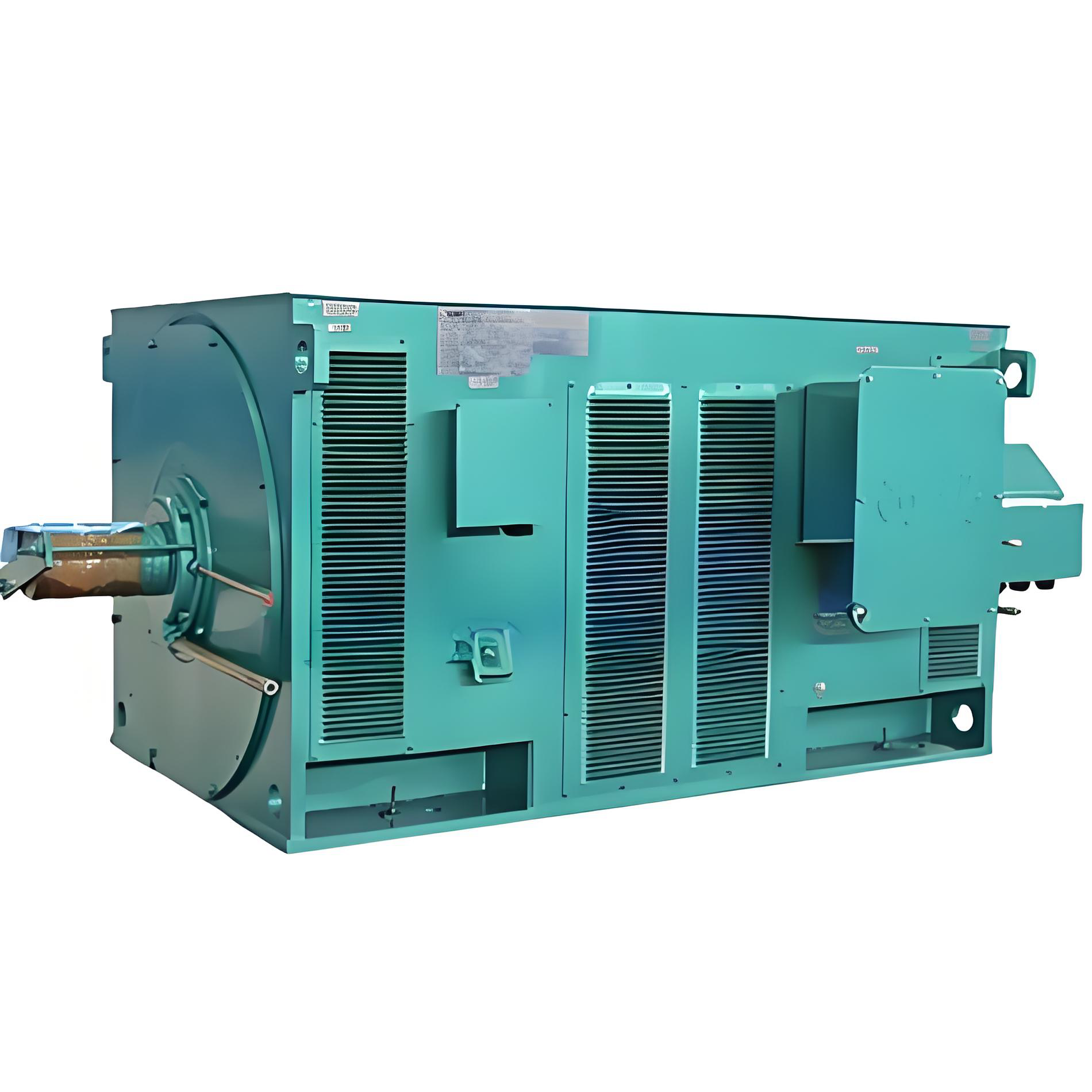

In the grand narrative of modern industrial production, electric motors serve as the “heart” of mechanical equipment. Their performance directly determines the operational efficiency and energy consumption costs of entire production lines. Faced with increasingly stringent environmental standards and the relentless pursuit of production capacity, enterprises no longer focus solely on price during selection. Instead, they prioritize equipment stability and total lifecycle value. It is precisely against this industry backdrop that...Sima JS MotorWith its outstanding squirrel-cage rotor design and the robust performance of medium-voltage asynchronous motors, it has gradually become the preferred power solution in heavy industrial sectors such as mining, machinery, metallurgy, and power generation.

Design Philosophy and Core Technical Advantages

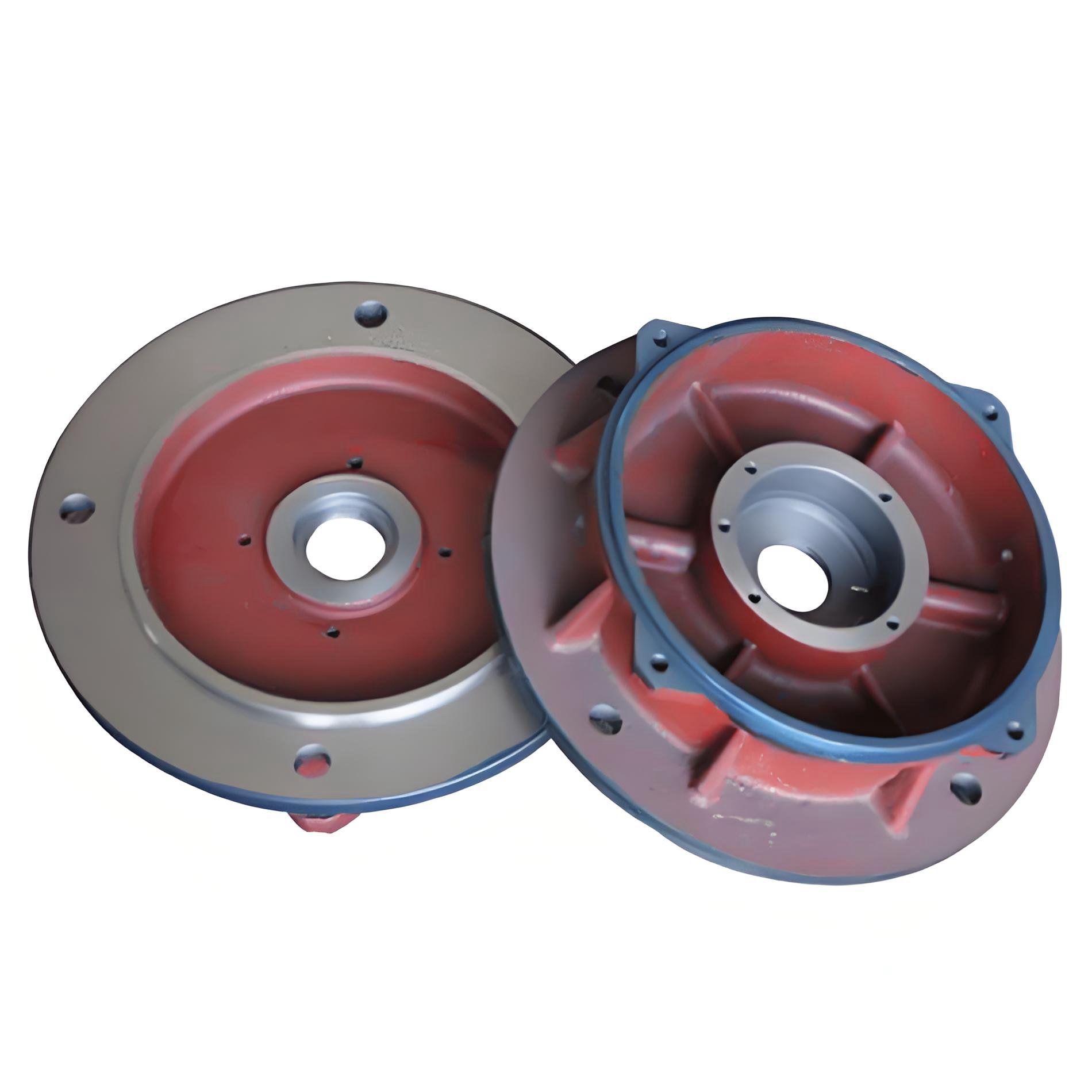

Sima JS MotorThe ability to stand out in fierce market competition is primarily attributed to its solid technical foundation. This series of motors is specifically designed to drive various general-purpose machinery, such as water pumps, ventilators, compressors, crushers, and more. Structurally, it adoptsCage rotor structureThis design not only simplifies the manufacturing process but also significantly enhances the reliability of motor operation.

Compared to traditional wound-rotor motors, the JS series features a more compact structure and significantly reduced maintenance requirements.For factories seeking long-term stable operation, this translates to reduced downtime for maintenance and a direct boost in production efficiency. Additionally, this motor employs an F-class insulation system treated with vacuum pressure impregnation (VPI), ensuring it maintains excellent insulation performance and mechanical strength even in harsh industrial environments characterized by humidity or dust.

Energy Efficiency and Operational Stability

Guided by the dual carbon goals, the energy efficiency ratio of electric motors has become a key consideration for enterprises during procurement.Sima JS MotorFrom the outset of design, fluid dynamics and electromagnetic field optimization were thoroughly considered. By enhancing the ventilation and heat dissipation system, temperature rise was effectively reduced. This not only extends the motor's service life but also demonstrates superior performance during actual operation.Low noise, low vibrationdistinctive characteristics.

It is worth noting that this series of motors permits full-voltage direct starting. If starting is performed by reducing the starting voltage when the user's grid capacity is insufficient, although the starting torque will decrease quadratically,Sima JS MotorIt continues to demonstrate excellent adaptability, capable of meeting load demands under various operating conditions. Its high energy conversion efficiency helps enterprises save substantial electricity costs over time in daily production, achieving a true win-win for both economic and environmental benefits.

Analysis of Practical Application Cases

To gain a clearer understanding of its performance, we can refer to a technical upgrade project at a large cement plant. The plant's original crusher drive system suffered from frequent failures and persistently high energy consumption. After introducingSima JS MotorAfter serving as the core drive unit, six months of operational monitoring data indicate that the equipment's failure rate has decreased by approximately 40%, while the overall system's average current value has significantly dropped under equivalent load conditions.

Particularly when handling high-intensity continuous operation, the motor's thermal stability is impressive. Even under high-temperature conditions during summer, the motor bearing temperature remains within the ideal range without requiring additional external forced cooling measures. This case study fully demonstrates the robust performance of this motor series in heavy-load starting and continuous operation.

Selection, Installation, and Maintenance Recommendations

AlthoughSima JS MotorHighly durable, yet proper selection and standardized installation remain essential to ensure optimal performance in practical applications. When selecting a motor, enterprises must rigorously verify the load's rotational inertia against the motor's permissible values to prevent overheating due to prolonged startup times. Additionally, during installation, precise coaxial alignment between the motor and driven machinery must be maintained to avoid additional vibration caused by misalignment, thereby further safeguarding performance.Sima JS Motorlong-term stable operation.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206