Industrial-grade high-efficiency energy-saving variable-frequency motor, delivering precise speed control and robust power.

Date: 2025-12-10 Categories: Faq Views: 4285

Excerpt:

In-Depth Analysis of Variable Frequency Motors: The Core Power Source for Industrial Energy Efficiency and Precision Control In today's wave of industrial automation, business owners and engineers face a common challenge: how to maximize energy savings and achieve precise equipment control while maintaining production efficiency. Conventional standard motors often struggle when confronted with frequent speed changes and variable load conditions, resulting in not only significant energy consumption but also increased failure risks.

Article Catalog[Hidden]

In-depth AnalysisVariable Frequency MotorThe Core Driving Force of Industrial Energy Efficiency and Precision Control

In today's wave of industrial automation, business owners and engineers face a common challenge: how to maximize energy efficiency and achieve precise equipment control while ensuring production efficiency? Conventional motors often struggle when confronted with frequent speed changes and variable load conditions, resulting in not only high energy consumption but also increased risk of equipment damage due to overheating. It is precisely against this backdrop that...Variable Frequency MotorAs a power device specifically designed for variable frequency drive applications, it has become the preferred solution for modern industrial drive systems due to its outstanding speed regulation performance and energy-saving characteristics.

What is a variable frequency motor?

Many people tend to confuse conventional motors with variable-frequency motors. Although they appear similar in appearance, they differ fundamentally in their design principles.Variable Frequency Motor(Variable Frequency Motor) is specifically engineered to accommodate the high-order harmonics and wide-range speed control output from variable frequency drives.

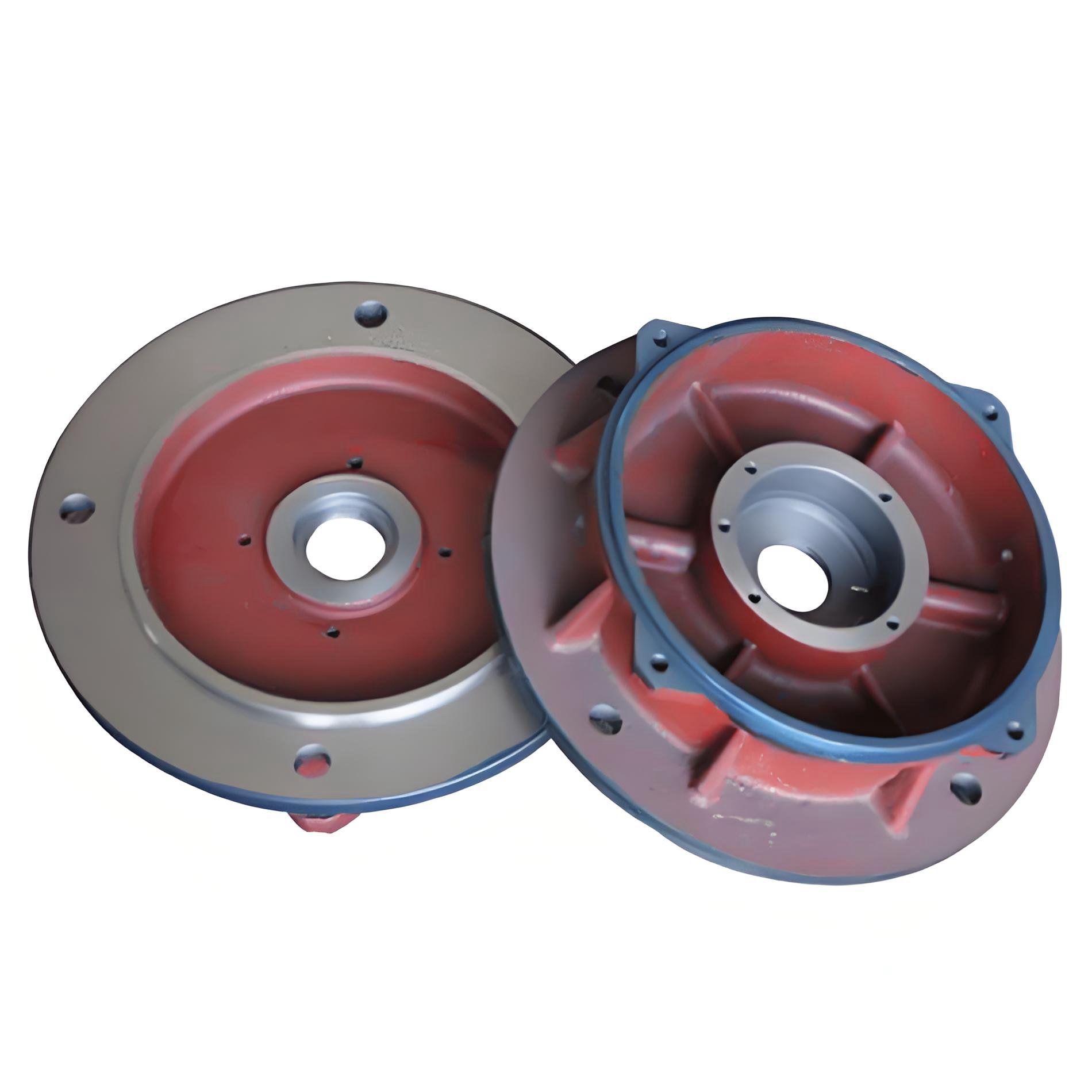

Compared to conventional motors, the most distinctive feature of variable frequency motors lies in theirHeat Dissipation SystemThe cooling fan of a standard motor is typically connected to the main shaft, and the lower the rotational speed, the poorer the cooling effect; whereas variable-frequency motors are equipped withIndependently Driven Axial Flow FanRegardless of motor speed variations, it maintains consistent and robust heat dissipation capabilities. This design ensures the motor will not burn out due to excessive temperature rise during low-frequency constant-torque operation, resolving the long-standing heat dissipation challenge associated with prolonged low-speed operation.

Core Advantages: From Energy Efficiency to Precision Control

1. Outstanding energy-saving performance

In fluid-driven applications such as fans and pumps,Variable Frequency MotorWhen used with variable frequency drives, the energy-saving effect is particularly remarkable. Traditional methods rely on valves to regulate flow, keeping motors running at full speed at all times, resulting in significant energy waste. With variable frequency speed control, motor speed adjusts in real time according to load demand. Based on fluid mechanics principles, shaft power is proportional to the cube of rotational speed. This means that even a 20% reduction in speed can lead to substantial energy savings.

2. Wide-band speed regulation capability

Variable Frequency MotorFeatures a wider speed regulation range. At low frequencies, it delivers stable constant torque output to meet the heavy-duty starting demands of cranes, extruders, and similar equipment. At high frequencies, it maintains constant power operation. Through specialized electromagnetic design, it effectively suppresses electromagnetic noise and vibration caused by high-frequency harmonics, ensuring smoother equipment operation.

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2025/11/1764034629-8956.jpg)

Case Study: Retrofit of a Pump Station at a Chemical Plant

To gain a more intuitive understandingVariable Frequency MotorTo illustrate its value, we can refer to a case study of a large chemical plant's circulating water system retrofit. The plant originally used multiple conventional three-phase asynchronous motors to drive water pumps, operating continuously at line frequency and relying on outlet valves to regulate flow. This approach not only resulted in high electricity costs but also caused extremely rapid valve wear.

When replacing the drive system withVariable-frequency dedicated motorAfter installing the new pumps and their control systems, the factory achieved automatic motor speed regulation based on real-time water pressure. Data shows the upgraded system achieved an average energy savings rate exceeding *35%*. Additionally, the implementation of soft-start technology eliminated the impact on the power grid during motor startup, significantly extending the service life of both pumps and pipelines while reducing maintenance costs by nearly 50%.

Enhanced Design for Insulation Strength

In addition to heat dissipation and speed regulation,Variable Frequency MotorTargeted reinforcement has also been implemented in the insulation structure. The high-frequency pulse voltage generated by the frequency converter can impact the motor's insulation layer. To address this, high-quality variable-frequency motors employCorona-resistant enameled wireWith its specialized insulation process, it can withstand repeated impacts from high-frequency pulse voltages, preventing the inter-turn short-circuit failures common in standard motors under variable-frequency drives. This ensures the continuity and safety of industrial production.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206