Simo motors successfully solved the rotor open-circuit fault of a mining company's JR series wire-wound motor.

Date: 2023-08-21 Categories: Cases Views: 964

Excerpt:

This article records in detail the whole process of repairing the open-circuit rotor winding of JR137-4 type wire-wound motor for a large mining company by the professional technical team of Simo Motor. Through accurate fault diagnosis and professional winding process, we not only solved the rotor winding open-circuit problem, but also established a perfect equipment health management system for the customer through a comprehensive preventive maintenance program. This case demonstrates the technical strength and service quality of Simo Motor in the field of JR series wire-wound motor repair.

Article Catalog[Hidden]

- I. Fault Background: Production Interruption, Urgent Assistance Requested

- II. In-Depth Diagnosis: Pinpointing the Fault Location

- III. Professional Maintenance Plan and Implementation

- IV. Maintenance results and customer value

- V. Case Summary and Technical Extension

- VI. Simo Motor's Professional Advantages

I. Fault Background: Production Interruption, Urgent Assistance Requested

Customer Information:

- Client OrganizationA large mining group's mineral processing plant (name withheld at client's request)

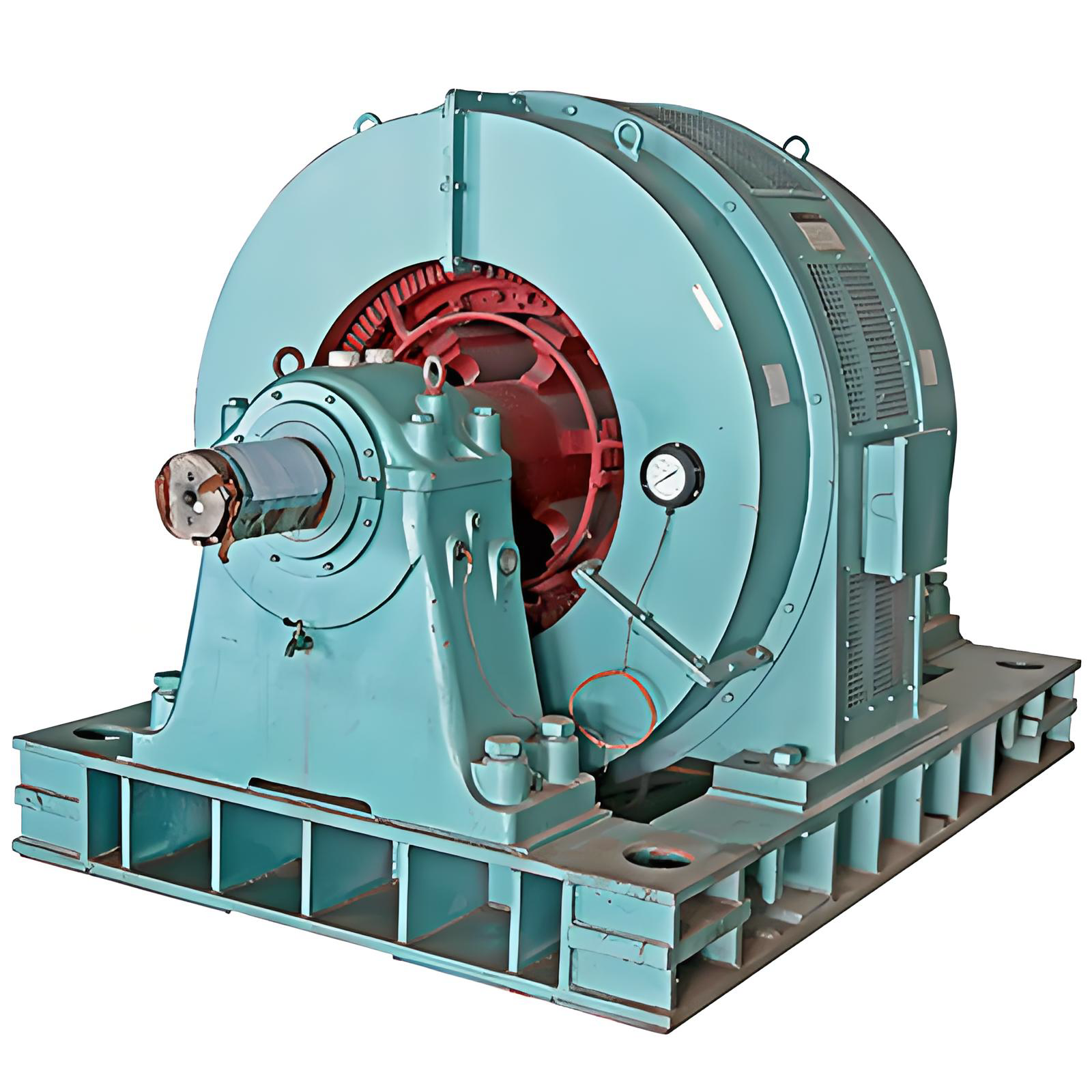

- Equipment TypeJR137-4 Wound-rotor Induction Motor

- Key ParametersRated power: 220 kW Rated voltage: 6 kV Rated rotor voltage: 275 V Rotational speed: 1480 r/min

- application scenarioCore Ball Mill Drive Equipment

- Fault Symptoms:

- Sudden shutdown during operation; motor fails to restart.

- The electronic control system displays "Rotor circuit abnormality."

- The slip ring area exhibits distinct discharge marks accompanied by a burning smell.

II. In-Depth Diagnosis: Pinpointing the Fault Location

Simo motorsUpon receiving the service request, the technical team responded immediately and arrived on-site within 4 hours to conduct system diagnostics:

1. Preliminary Detection and Analysis

- Using a multimeter to test the three-phase windings of the rotor, an open circuit was detected in the B-phase winding.

- Insulation Resistance Measurement: Rotor winding insulation resistance to ground is 0.8 MΩ (standard requirement ≥ 1 MΩ).

- Inspecting the slip ring assembly: One of the slip rings was found to have severe surface burn damage.

2. Precision Diagnostic Localization

- Perform scanning inspection using a winding interturn tester

- Performing temperature distribution analysis on rotor windings using a thermal imaging camera

- Fault Pinpointing:

- The lead wire of the sixth winding in phase B of the rotor winding has broken.

- The welded joint between the slip ring and the winding has burned out.

- The slip ring surface exhibits uneven wear reaching 1.2 mm.

III. Professional Maintenance Plan and Implementation

Based on the diagnostic results, we have developed a specialized repair plan:

1. Rotor Winding Repair

- Detailed TeardownCarefully remove the faulty coil using specialized tools, taking care not to damage the iron core.

- Winding Repair: Rewind the coil to the original specifications, using F-class insulation material to enhance the heat resistance rating.

- Welding ProcessUse silver-phosphorus copper solder to ensure reliable and secure connections.

2. Slip Ring Assembly Repair

- precision machiningPerform precision turning on the slip ring surface to restore standard surface finish.

- Carbon Brush ReplacementReplace all carbon brushes and adjust spring pressure to standard value.

- Enhanced InsulationInstall a reinforced insulation sleeve between the slip ring and the shaft.

3. Professional Process Control

- Dynamic Balancing CalibrationCalibrated on a dedicated balancing machine, residual unbalance < 1.0 g·mm/kg

- Vacuum impregnation: Utilizing the VPI process to ensure thorough penetration of the insulating varnish

- High-temperature curing: Strictly follow the process curve for temperature ramping and curing.

IV. Maintenance results and customer value

1. Verification of Repair Effectiveness

- The test run after repair was successful on the first attempt.

- Rotor three-phase DC resistance balance ≤ 1%

- Insulation resistance restored to over 500 MΩ

- Parameters such as temperature rise and vibration exceed standard requirements.

2. Value Creation

- Rapid resumption of productionRepairs completed within 36 hours, reducing production downtime losses by approximately 800,000 yuan.

- Performance Enhancement:

- Motor efficiency improved by 3.21%

- Annual electricity savings are projected to reach approximately 45,000 kilowatt-hours.

- Carbon brush lifespan extended to twice the original duration

- Management OptimizationAssist in establishing a dedicated maintenance plan for the rotor system.

V. Case Summary and Technical Extension

1. Key Points for Maintenance of JR Series Motors

- Wound-rotor motors require particular attention to the coordination between the rotor windings and the slip ring system.

- Regularly inspect the wear condition of carbon brushes and spring pressure.

- Monitor the formation status of the oxide film on the surface of the slip ring

2. Preventive Maintenance Recommendations

- Daily Inspection:

- Check the carbon brush wear daily.

- Measure the insulation resistance of the rotor windings weekly.

- Inspect the surface condition of slip rings monthly.

- Professional Maintenance:

- Perform rotor dynamic balancing verification every six months.

- Annual winding interturn insulation testing

- Establish a Rotor System Operation Record

VI. Simo Motor's Professional Advantages

This case study demonstrates Simo Motor's expertise in the repair of wound-rotor motors:

- Professional equipment:

- Equipped with large dynamic balancing machines and VPI impregnation equipment

- Equipped with professional winding machines and testing instruments

- Technical Team:

- With over 20 years of experienceWound Motor RepairExperience

- Holders of Electromechanical Professional Qualification Certification

- Process Standards:

- Strictly implement the ISO 9001 Quality Management System

- Adopting internal process standards that exceed national standards

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206