Excerpt:

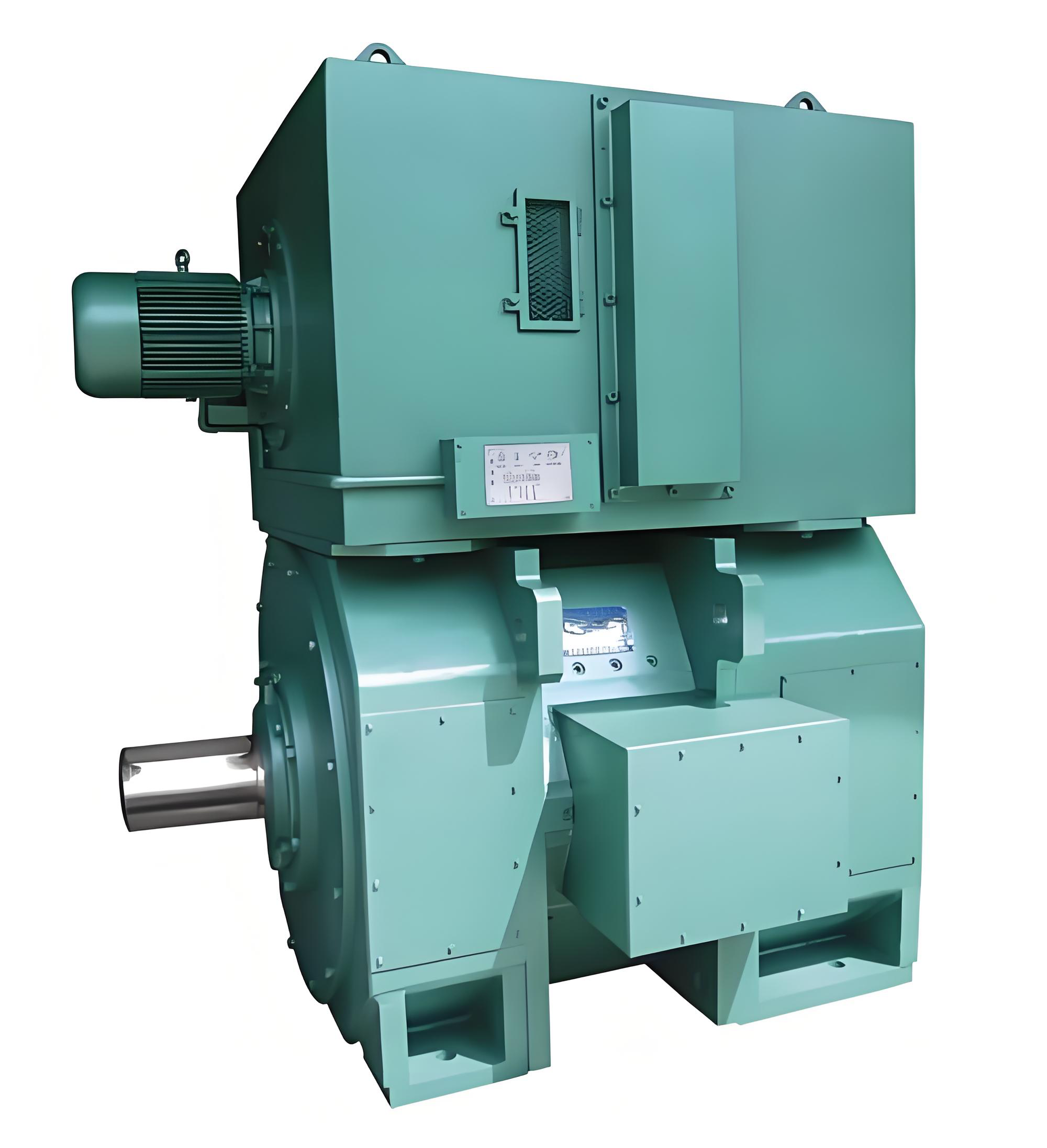

Xi'an TaiFu Xima Z-series DC motors feature an advanced design with a polygonal laminated structure for the stator frame, maximizing space utilization. This design delivers compact dimensions, lightweight construction, and superior performance. The stator yoke, poles, and armature cores are all constructed from high-quality cold-rolled silicon steel laminations, ensuring excellent magnetic conductivity.

Xi'an TaiFu Xima Z SeriesDC motorModel Description

Taking Z355-1A as an example. Z denotes a DC motor (product series code); 355 indicates the motor center height in millimeters; the number 1 after the hyphen represents the foot hole center distance code (B dimension), with four lengths from shortest to longest denoted by numbers 1, 2, 3, etc.; A signifies the motor category code, where letters A and B respectively represent Class I and Class II Kogaku-sho motors.

Xi'an TaiFu Xima Z Series DC Motor Overview

Z Series Medium-Sized DC Motors: Center Height: 355–710 mm Following the successful development of the Z4 small DC motors, our factory has introduced this new series of medium-sized DC motors. The performance, external dimensions, mounting specifications, and technical requirements of this series comply with the JB/T9577-1999 standard and IEC international standards. All mechanical dimensions and tolerances conform to ISO standards.

Xi'an TaiFu Xima Z Series DC Motors can be widely used in various industrial sectors, including metallurgical rolling mills, metal-cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Xi'an TaiFu Xima Z-series DC motors feature advanced design with a polygonal laminated structure for the stator frame, maximizing space utilization and delivering compact size, light weight, and superior performance. The stator yoke, poles, and armature cores are all constructed from high-quality cold-rolled silicon steel laminations, ensuring excellent magnetic permeability and overall thermal performance.This series employs rolling bearings with a non-stop oil-replenishment design and features F-class insulation throughout.

Z Series Xi'anTaifu Simo MotorNot only can it be powered by DC generator sets, but it is even more suitable for stationary rectifier power supplies. Furthermore, it features low rotational inertia, excellent dynamic performance, and the ability to withstand high load variation rates. It is particularly well-suited for control systems requiring smooth speed regulation, high efficiency, automatic speed stabilization, and responsive performance.

Xi'an TaiFu Xima Z Series DC Motor: Structural Installation Type, Protection Rating, and Cooling Method

1. The mounting types of Z-series motors comply with GB/T 997 and IEC 34-7 "Codes for Designations of Structure and Mounting of Electric Machines."

2. The Z-series motors comply with GB/T 4942 and IEC 34-5 standards for "Degrees of Protection Provided by Enclosures for Electric Motors," featuring two enclosure protection ratings: IP23 and IP44.

3. The Z series motors employ four cooling methods in accordance with GB/T1993 and IEC34-6 "Methods of Cooling Electric Motors." Users requiring other protection ratings or cooling methods may negotiate separately. For standard models in this series, the cooling air inlet is located at the drive end (non-commutator end) of the motor.

3.1 IC06: External ventilation with built-in blower; (Protection rating: IP23)

3.2 IC17: Cooling air inlet via ductwork, outlet via louvered exhaust; (Protection rating: IP23)

3.3、IC37: Both cooling air inlet and outlet are ducts; (Protection rating: IP44)

3.4、ICW37A86: Fully enclosed with air/water cooler. (Protection rating: IP44)

4. The required cooling air volume, air pressure, and fan motor power for each frame size are shown in Table 1.

5.Xi'an Simo MotorThe terminal box is located on the right side of the frame when viewed from the drive end (non-shaft extension end), referred to as the standard box. If the user requires the terminal box to be positioned on the opposite side, specify a reverse box.

Xi'an TaiFu Xima Z Series DC Motor Operating Conditions

1. The rated power of the motor refers to conditions where the altitude does not exceed 1000 meters and the ambient air temperature does not exceed 40°C.

2. Both the armature circuit and excitation circuit of this series of motors can be powered by controllable power supplies or by DC generator sets.

3. The operating environment for this series of motors should not contain acidic, alkaline, or other gases that corrode insulation.

4. Motors can be installed in harsh environmental conditions, but the appropriate cooling method and protection rating must be selected to ensure normal operation.

5. For motors used in marine applications, humid tropical regions, or environments with salt spray, moisture, etc., separate agreements shall be made.

6. When the motor is supplied by a stationary rectifier power source, the rectifier shall have no fewer than six pulses. At rated base speed, rated voltage, and rated load current, the peak ripple factor of the power supply shall not exceed 10%.

Xi'an TaiFu Xima Z Series DC Motor Product Performance

1. The standard operating mode for this series of Xi'an Xima motors is continuous load. Should other operating modes be required, separate agreements must be made.

2. This SeriesSimo motorsThe standard rated voltages are 220V, 330V, 440V, 550V, 660V, and 750V. Other voltage levels can be derived and must be agreed upon at the time of ordering.

3. The basic configuration of this series of Xima motors is separately excited, with a standard excitation voltage of 220V. Other excitation voltages may also be derived. Forced excitation is permitted for this series, with the forced excitation voltage not exceeding 500V. During forced excitation, the excitation current may momentarily slightly exceed the rated excitation current. However, once stabilized, the excitation current must not exceed the rated excitation current value.

4. Short-term overload capacity of this series of electric motors:

Class A motors can withstand short-term (one-minute) overloads as specified in Table 2;

Class B motors can withstand the short-term (one-minute) overload specified in Table 3;

Occasional short-time overload capability refers to the motor's ability to withstand loads exceeding its rated capacity for one minute during rare occurrences or emergencies. It is recommended that the instantaneous trip device of the circuit breaker be set according to this occasional short-time overload capability.

Frequently used short-time overload capability refers to the motor's ability to repeatedly withstand loads exceeding its rated capacity as part of its normal operating cycle. Following short-time overload operation, the motor must be run under light load conditions to ensure that the root mean square (RMS) value of the load over the entire load cycle does not exceed its borderline rating.

Class B motors shall be capable of withstanding the following continuous loads:

When operating continuously with a load rated at 115% within the rated armature voltage and rated speed range, the temperature rise will be higher under this load. Other characteristics may differ from those specified for operation under rated conditions.

Within the rated armature voltage and rated speed range, after continuous operation under rated load, the motor shall operate for two hours under a load of 125% rated power without exceeding the specified temperature rise. Other characteristics may differ from those specified for operation under rated conditions.

The motor permits extended overload durations at lower overload multiples. For Class B DC motors, occasional operation at overload multiples up to 2.5 times the rated base speed is permitted for periods not exceeding 15 seconds (subject to manufacturer approval).

5. Speed Adjustment Rate:

The rotational speed of this series of motors is not specified. Should users have special requirements, these should be agreed upon at the time of ordering.

6. Current change rate:

At all speeds and loads, the current change rate (di/dt) for this series of motors is permitted up to 200 times the rated current per second.

7. Noise and Vibration:

The noise levels of Z-series motors comply with the requirements of GB/T 10069 "Determination of Noise of Rotating Electrical Machines and Limits" and IEC 34-9 "Limits for Noise of Electric Machines".

The vibration of Z-series motors complies with the requirements of GB/T 10068 "Rotating Electrical Machines - Vibration - Measurement Methods and Limits" and IEC 34-14 "Vibration of Electrical Machines - Measurement Methods and Limits."

Capacity Selection for Xi'an TaiFu Xima Z Series DC Motors

Category I: DC Motors (Class A)

Users of this type of Cima motor can select the motor model and specifications based on their required capacity, speed, and voltage.

Category 2: DC Motors (Class B)

The rated output power of this type of Cima motor is slightly lower than that of Class A motors with the same center height and the same foot-to-shaft axial length.Other specifications remain largely consistent. If Class B motor specifications are known, Class A specifications may be used for preliminary selection. During initial selection, increase the rated power of the Class B motor by approximately 25% to 30%. Then, using this increased power rating, select the corresponding model from the Class A specifications. However, replace the letter "A" with "B" in the corresponding model, while retaining the original power rating (i.e., the Class B motor's original power).The final model and specifications should be determined through consultation between the user and the manufacturer.

Application requirements:96KW 220V 185r/min Class B motor → Amplified power 25%, corresponding to 120KW 220V 185r/min Class A motor → Refer to Class A specifications for a similar model: A450-2A 11KW 220V 178r/min → Change model to: Z450-2B,This model approximately represents the 96kW 220V 185r/min Class B motor and can preliminarily meet the application requirements.

The conversion relationship is:

First, locate the rated voltage in the corresponding technical data sheet that is closest to UN, NN, PN, and their derivatives, and lower than the newly derived supply voltage. Note the corresponding rated base speed and rated power. Generally, the higher the voltage and rotational speed, the greater the output power; conversely, the lower the voltage and speed, the smaller the output power.

Xi'an TaiFu Xima Z Series DC Motor Accessories and Spare Parts

1. Attachments

This series of Xima motors can be equipped with a speed protection system comprising a tachogenerator (ZYS or ZCF type), centrifugal switch, and either a photoelectric pulse sensor or photoelectric encoder (SZGB type or TPD-J type). Users should specify these requirements in the contract when placing an order.This series of Xima motors may also be equipped with other models and types of speed protection devices provided by the user. However, this must be negotiated at the time of ordering, and the user must provide the external installation dimension drawings of the speed protection device to be installed in advance.

The stator windings and bearings of this series of Cima motors can accommodate temperature monitoring or thermal protection devices, with the terminal wires routed into the motor's terminal box. Users should discuss and specify these requirements when placing orders.

This series of motors can be equipped with internal heaters according to user requirements. This must be discussed at the time of ordering and specified in the contract.

2. Spare parts

Based on user requirements and as specified in the purchase contract, each motor can be supplied with the following spare parts: one set of brushes, one set of brush holders and brush holders.

Xi'an Xima Electric Motor Quality Assurance

Xi'an Xima Electric Motor (Group) Co., Ltd. is a major domestic enterprise specializing in the production of large and medium-sized, high and low voltage, AC and DC motors. As a systematic power system provider, it integrates motor design and manufacturing, electrical control, mechanical processing, mold making, casting, transportation, and other automated, complete engineering solutions. Its production and sales scale ranks among the top in China's motor industry, maintaining a high-speed growth trajectory for seven consecutive years.The company was ranked among China's Top 500 Machinery Enterprises in 2004 and placed 58th in China's Electrical Equipment Industry in 2005. In 1995, it became the first in the industry to obtain ISO 9001-1994 Quality Management System certification. In August 2005, it passed the ISO 9001-2000 Quality Management System certification by the China Quality Certification Center (CQC).In May 2006, it obtained ISO14000 Environmental Management System and OHSAS18000 Occupational Health and Safety Management System certifications, alongside European “CE,” American “UL,” and China's mandatory “CCC” safety certifications. The company holds AAA-level quality and credit ratings. Its flagship products have earned honors including “Ministry/Provincial/Municipal Famous Brand Products,” “Xi'an Exempted Inspection Products,” and “China's Glory Famous Brand Products.”

To enhance the quality of all electromechanical products and strengthen pre-sales and after-sales services, ensuring customer confidence and satisfaction, Xima Electric resolutely implements the “Quality Assurance Declaration” issued by eight research institutes and design centers within the machine tool industry under the Ministry of Machinery Industry. We earnestly implement all provisions of this declaration and strictly adhere to the regulations of the ISO9001:2000 Quality Management System, guaranteeing the following:

I. Strictly implement relevant national standards and rigorously manufacture and inspect products in accordance with standard specifications and contract technical requirements. Non-compliant products shall not be shipped from the factory.

II. After final assembly and integrated debugging of all finished products, including measurement bases, assembly personnel shall conduct a 72-hour operational test before submitting for inspection. Strictly adhere to relevant standards for performance verification and reliability testing to enhance product reliability and eliminate early-stage failures.

III. Under normal sales conditions, the aforementioned complete units shall be delivered strictly on schedule. Functional components are guaranteed for supply within three months, with advance delivery possible under special circumstances. In the event of delays, compensation shall be provided in accordance with the “Quality Step-Up ”97" initiative.

IV. Should customers encounter quality issues during product use, we guarantee a response within 24 hours of receiving notification. For on-site service requests, we will initiate action within 48 hours and ensure technicians remain on-site until the issue is resolved.

V. Products are shipped with complete technical documentation. Any product quality issues are covered by the warranty, including repair, replacement, or refund. If the product fails to meet factory specifications after repair, it will be replaced or refunded.

VI. Xima motors come with a lifetime warranty covering parts and labor.

Xi'an TaiFu Xima Z Series DC Motor Ordering Instructions

1. Before placing an order, please review the Xi'an Xima Electric Motor product catalog to determine the model, specifications, and other relevant data for the required product. Whenever possible, select standard specifications listed in the catalog. In the purchase contract, clearly specify the motor model, power rating, voltage, rotational speed, excitation method, excitation voltage, and structural mounting configuration.

2. Any special requirements for the product, such as dual shaft extensions, reversed cable box positions, or counter-clockwise rotation of the shaft, must be explicitly stated in the contract.

3. If the required product specifications are not listed in this catalog, or if there are other special requirements, a contract or trial production agreement shall be signed upon mutual agreement between both parties.

4. For all Xi'an Xima Electric Motor products, accessories other than the motor shaft extension key are not included in the supply scope. Should customers require accessories or spare parts—such as brushes, brush holders, etc.—please specify the names, specifications, and quantities of the required accessories or spare parts in the contract beforehand.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206