Article Catalog[Hidden]

- YR IP23 Series Low-Voltage Three-Phase Asynchronous Motors: Efficient and Reliable Industrial Power Solutions

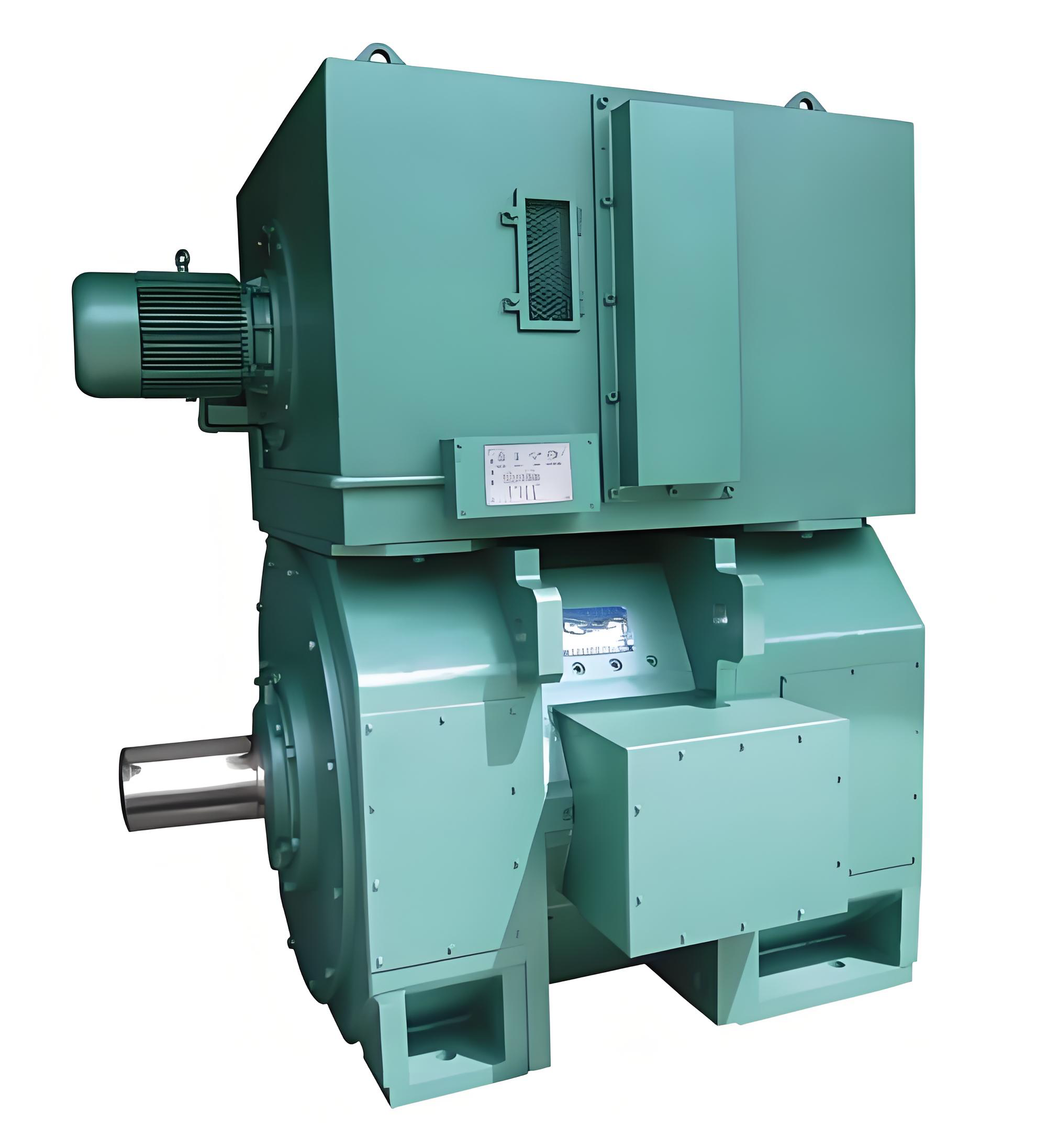

YR IP23 Series Low Voltagethree-phase asynchronous motorHigh-Efficiency, Reliable Industrial Power Solutions

In the industrial power sector, the YR IP23 series low-voltage three-phase asynchronous motors are characterized by theirOutstanding starting performance和Flexible speed regulation characteristicsIt has become the ideal power unit for starting and operating heavy-duty equipment across various industries.

YR IP23 series low voltage three-phase asynchronous motoris aProtected-wound rotor three-phase asynchronous motorAdoptionAdvanced electromagnetic design and premium materialsmanufacture, possessingHigh starting torque, excellent speed regulation performance, reliable operation, and easy maintenance.This series of motors strictly adheres toJB/T 5269-2018National standards such as "Technical Specifications for YR3 Series (IP23) Three-Phase Asynchronous Motors," with power ratings and mounting dimensions conforming toInternational Electrotechnical Commission (IEC) standardsfor easy equipment integration and replacement.

I. Product overview and technical characteristics

1. Product profile

The YR IP23 series is specifically designed forIndustrial Power TransmissionWound-rotor three-phase asynchronous motors. This series of motors adoptsProtected construction designThe rated voltage is380 voltsThe rated frequency is50 hertzThe power range extends from4 kilowatts to 132 kilowatts(Part of the series has been extended to)355 kilowatts), coveringFrame size 160 to 400capable of meeting the power demands of various industrial scenarios。

As the core of industrial power, the YR IP23 series motors are suitable for driving various heavy-duty machinery and equipment, such asCompressor, crusher, winch, fan, pump, conveyor belt等. itsProtected constructionEnsures reliable operation across diverse industrial environments, making it the ideal prime mover for mining, machinery manufacturing, petrochemicals, power plants, and various industrial and mining enterprises.。

2. Core technical characteristics

The YR IP23 series motors incorporate multiple innovative technologies and offer significant performance advantages:

- Outstanding starting performance: The electric motor can operateDelivers greater starting torque at lower starting currentsThe starting torque is greater than that of squirrel-cage rotor motors, effectively reducing the impact on the power grid.

- Flexible speed regulation characteristicsThe wound rotor structure enables the motorFeatures a certain speed adjustment rangeSpeed adjustment can be achieved via an external resistor to meet the demands of different operating conditions.

- Highly efficient electrical characteristics: The motor hasHigh efficiency, excellent performance, low noise, and reliable operationFeatures such as high energy efficiency levels and significant energy-saving effects.

Technical parameters and performance indicators

The YR IP23 series low-voltage three-phase asynchronous motors cover a wide range of technical specifications to meet the power requirements of diverse industrial applications:

Main technical parameters

Description of performance characteristics

YR IP23 Series Motors inStart-up characteristics, operating performance, and speed regulation rangeExcellent performance in all areas:

- Excellent starting characteristics:Low starting current but high starting torqueIt can effortlessly start heavy-duty equipment, resolving the issue of squirrel-cage rotor motors failing to start due to insufficient capacity in the power supply lines.

- Wide speed rangeBy connecting an external resistor to the rotor circuit, it is possible toSmoothly adjust the rotational speed within a certain rangeto meet different process requirements

- Low vibration and low noise: AdoptionOptimized design and precision manufacturing processesThe motor runs smoothly with low vibration and low noise.

III. Structural design and configuration

1. Motor body structure

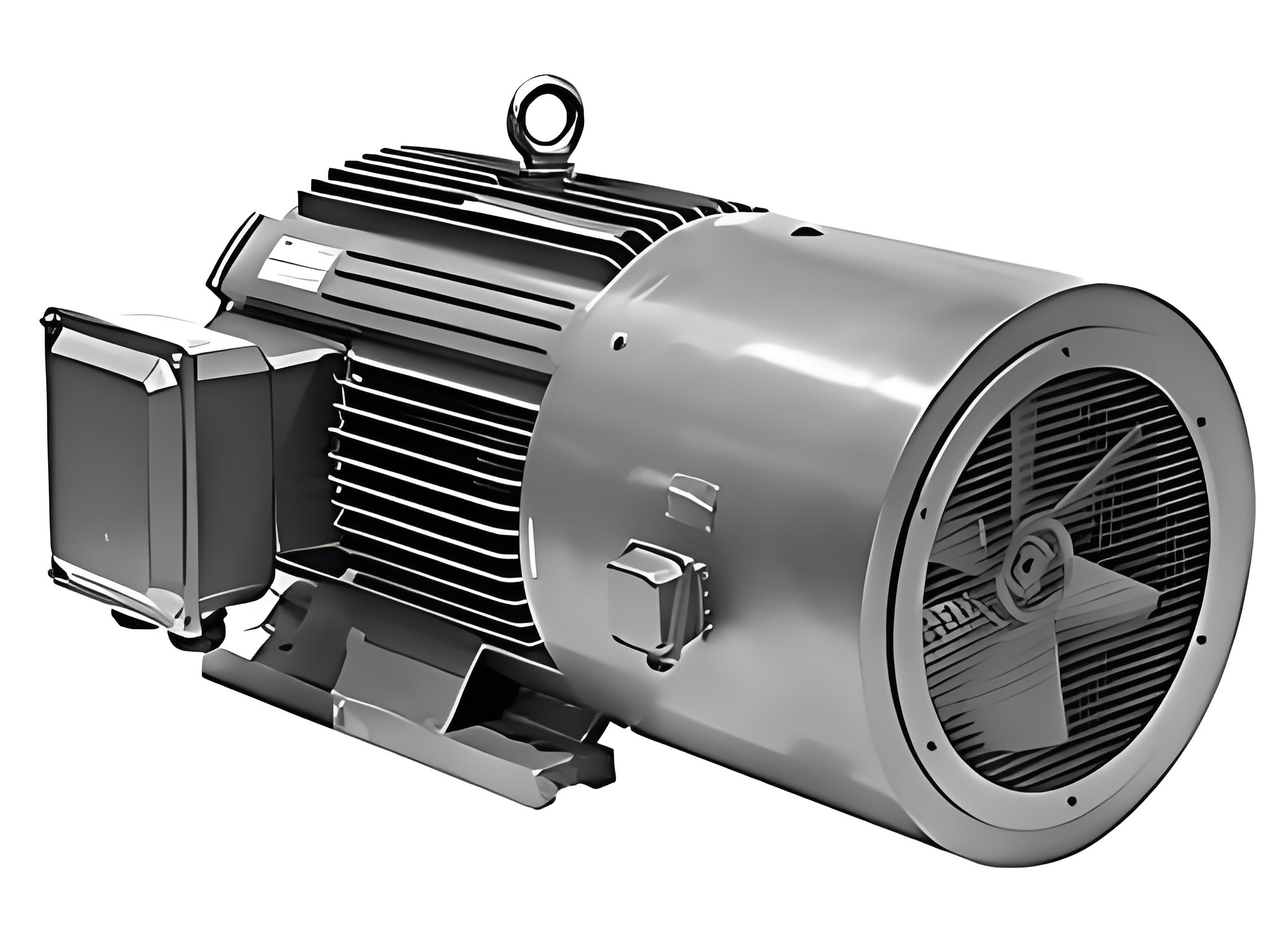

YR IP23 Series Low-Voltage Three-Phase Asynchronous Motors AdoptProtected construction designEach component is carefully designed and optimized:

- Protective housing design: The protection class of the motor isIP23canPrevent fingers from touching electrically charged conductors or rotating parts of the enclosure.mergePreventing the entry of small solid foreign bodies larger than 12 mm in diameterwhile also being able toPrevents dripping of water at an angle of 60 degrees or less along a vertical line into the motor.offers superior protection compared to traditional drip-proof designs

- Stator structure: The stator winding is made ofClass B insulationReliable insulation performanceSome models feature a stator that employsFlat copper wire formed into rigid windings or round copper wire loosely embedded into flexible windingsThe winding section is securely fastened and treated with varnish, ensuring reliable electrical strength and mechanical strength for robust durability.

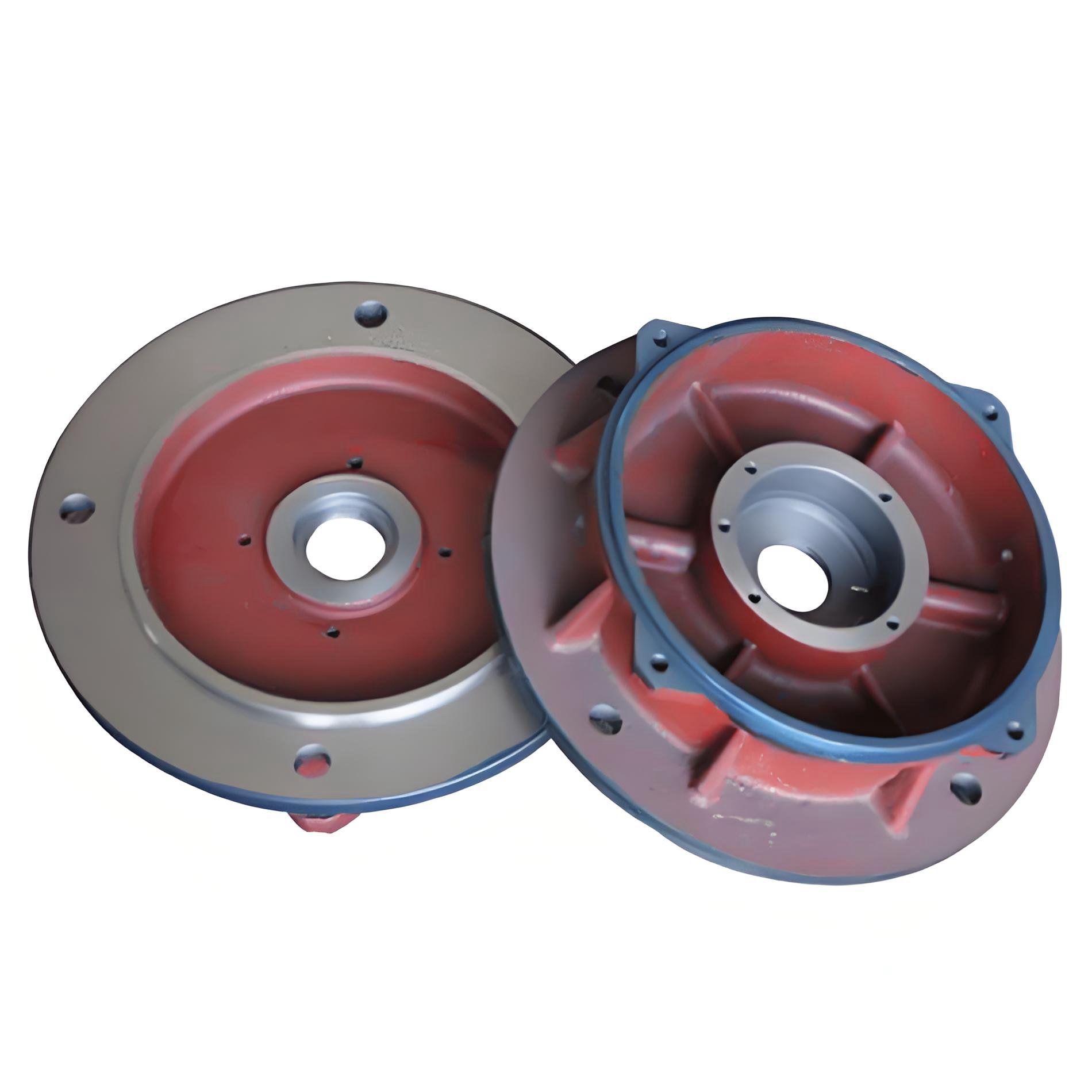

- Rotor construction: AdoptionWound rotor structureConnected to an external resistor via slip rings. The rotor winding employsQuality materials和Precision Manufacturing ProcessEnsure smooth and reliable motor operation

2. Wiring and Cooling System

The YR IP23 series motors feature specialized designs for wiring and cooling:

- Junction Box Design: Junction box wiringSix (H280) or three (H315–335) output terminalsThe wiring method is△Connection Methodfor easy electrical connection

- cooling system: AdoptionIC01 Cooling Method(Self-fan cooling), through the internal fan to form air circulation, effectively take away the heat generated by the motor, to ensure that the motor continues to run stably under the rated load.

IV. Application areas and scenarios

YR IP23 Series Low-Voltage Three-Phase Asynchronous Motors are widely used across numerous industrial sectors due to their excellent starting characteristics and reliable operational performance:

1. Heavy industry

- Mining industry: for drivingCrushers, winches, hoistsHeavy-duty equipment, such as heavy-duty equipment, to withstand harsh working conditions

- Metallurgical industry: Applied toRolling mills, compressorsand other equipment, providing reliable power support

- Power industry: forpower plantsof various auxiliary equipment, such asFans, pumps等

2. General industrial areas

- Compressor and pump equipment: Applicable toCompressors, pumpsand other equipment, providing efficient power solutions

- transmission mechanism: Applied toConveyor belts, transportation machineryMaterial handling equipment to meet the needs of continuous operation

- cutting machine: for all kinds ofMachine ToolsThe drive provides a stable power output

3. Special application scenarios

The YR IP23 series motors are particularly suitable for the following special operating conditions::

- Requires greater starting torque than squirrel-cage rotor motorsthe occasion

- The feeder line capacity is insufficient to start the squirrel-cage rotor motor.the situation

- Long startup time and frequent startupsspecifications

- Requires fine-tuning of speedapplication

- Synchronously rotate with the "electric shaft"Special process requirements

V. Product Advantages and Values

1. Operational reliability

The YR IP23 series motors offer distinct advantages in reliability:

- Rugged structural design: AdoptionProtected constructionIt can withstand mechanical and thermal stresses under various working conditions to ensure long-term stable operation.

- High-quality insulation systems: AdoptionClass B insulationReliable insulation and long life

- Good environmental adaptability: The motor is suitable for use at altitudes ofNot exceeding 1000mAmbient air temperature-15°C to +40°COperates in relatively clean industrial environments

2. Energy efficiency economics

The YR IP23 series motors offer significant economic benefits:

- Reduce inrush current:Lower starting currentReduce the impact on the power grid and lower the capacity requirements for power supply equipment.

- Enhance startup capabilities:Higher starting torqueEnables smooth startup of heavy-duty equipment, reducing equipment failure rates.

- Low life cycle costs:Long life design和Low maintenance requirementsDramatic reductions in total life cycle costs

3. Ease of maintenance

This series of motors has been designed with ease of maintenance in mind:

- Maintenance-friendly structural design: Protected construction makes routine inspection, maintenance and overhaul easier.

- modular design: Modularized design of key components to reduce maintenance difficulties and spare parts inventory

- Long life design: AdoptionQuality Insulation SystemsLong design life, long maintenance intervals

VI. Installation and use guide

1. Installation environmental requirements

The YR IP23 series low-voltage three-phase asynchronous motors have specific requirements for the installation environment:

- environmental conditions: Suitable for use at altitudeNot exceeding 1000mAmbient air temperature-15°C to +40°COperates in relatively clean industrial environments free of flammable, explosive, or corrosive gases.

- humidity conditionThe average relative humidity for the wet month is90%At the same time, the average monthly minimum temperature does not exceed25°C

- mounting position: Ensure adequate space around the motor for cooling ventilation and maintenance

2. Installation and commissioning

Correct installation and commissioning is the key to ensure the safe operation of the motor:

- Startup RequirementsWhen the motor startsA starting resistor must be connected in advance in the rotor circuit.,Direct short-circuiting of the rotor windings for starting is not permitted.

- transmission methodThe motor transmission method can beCouplings, spur gears, or belt drives

- electrical connection: Properly wire the motor in accordance with the motor nameplate and wiring diagram to ensure that thereliable grounding

VII. Services and technical support

1. Quality assurance systems

The production of the YR IP23 series low-voltage three-phase asynchronous motors adheres to strict quality standards:

- standards compliance: The products strictly follow theJB/T 5269-2018National and industry standards

- Strict testing process: In the manufacturing process afterMultiple rigorous testsEnsure that the performance of the product meets the requirements of the standard

- Comprehensive performance testing: Each motor isRigorous factory testingEnsure reliable product quality

2. After-sales service commitments

The supplier provides customers with comprehensive after-sales service support:

- Professional Technical Support: Provide professional consulting services for product selection and installation guidance

- Rapid Response Mechanism: Respond to and resolve customer issues in a timely manner upon receipt of after-sales service requests

- Ongoing services: Provide customers with long-term technical support and service guarantee

YR IP23 Series Low-Voltage Three-Phase Asynchronous Motors, with theirOutstanding starting performance、Flexible speed regulation characteristics和Reliable operational performanceIt has become the industrial powerhouse of theIdeal Solution. ByContinuous technological innovation和Strict quality controlEnsure that every YR IP23 series motor can operate inHarsh industrial environmentssubscribeSafe, stable and efficientThe power of the support.

Choosing the YR IP23 series low-voltage three-phase asynchronous motor means choosingReliable equipment performance和Complete technical servicesWe are looking forward to cooperating with you. We are looking forward to cooperating with you to jointly promote the progress and development of energy-saving technology in the industrial field.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206