Article Catalog[Hidden]

- End caps and flanges for Simo motors: core components for precision protection and efficient transmission

- 01 Product overview: Structural support and sealing barriers for motors

- 02 Core function: multiple roles to ensure stable operation of the motor

- 03 Technical characteristics: exquisite craftsmanship to create excellent performance

- 04 Areas of application: broad adaptability with multi-industry coverage

- 05 Technical parameters: accurate data to support product selection

- 06 Selection Guide: Scientific Selection to Ensure the Best Match

- 07 Service support: all-round protection of customer needs

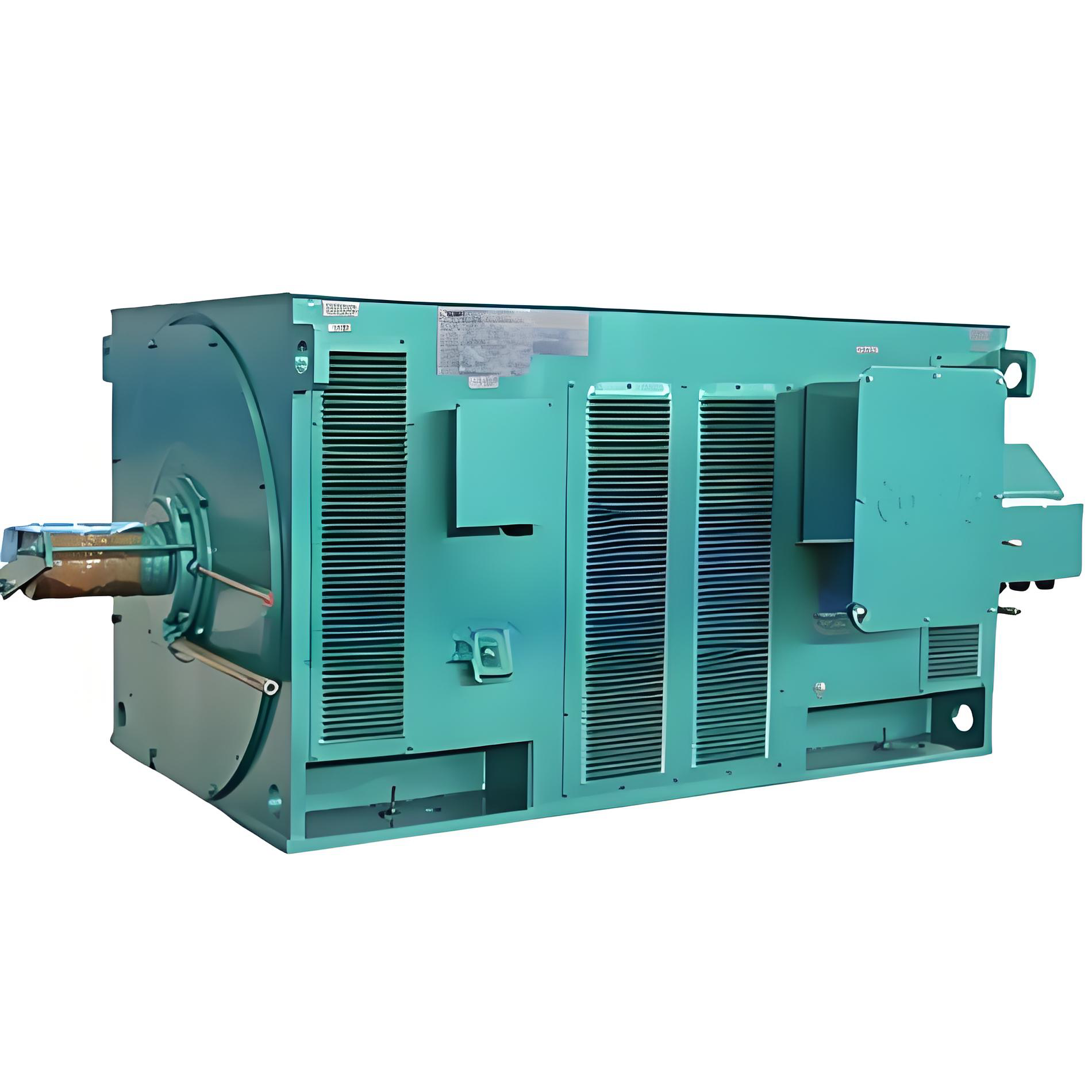

Simo motorsEnd caps and flanges: the heart of precision protection and efficient drives

In the motor system, although the end cover and flange are not the core electromagnetic components, they are the key components to ensure the stable operation of the motor.

Simo motor end caps and flangesIt is the motor structure in theKey mechanical components, respectively.Sealed Protection与Connection supportThe important function of the Simo motors utilizeQuality materials和Precision Manufacturing ProcessTo ensure that every end cap and flange has aExcellent mechanical strength、Precise dimensional tolerances和Long-lasting durabilityThe motor is designed to provide a solid guarantee for the overall performance of the motor.

01 Product overview: Structural support and sealing barriers for motors

In motor construction, end caps and flanges areIndispensable basic components, which together form the motor'sExternal support system and internal sealing environment。

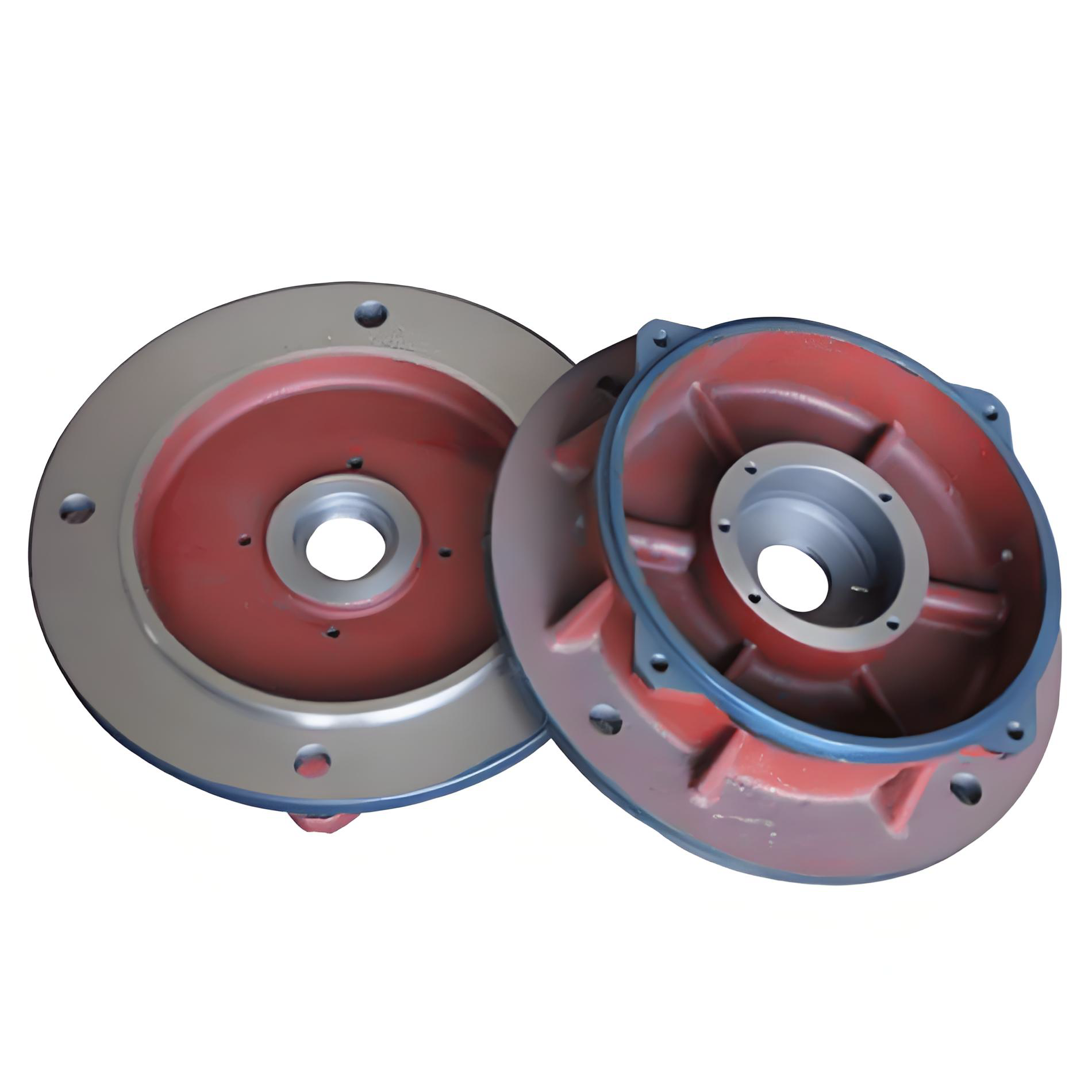

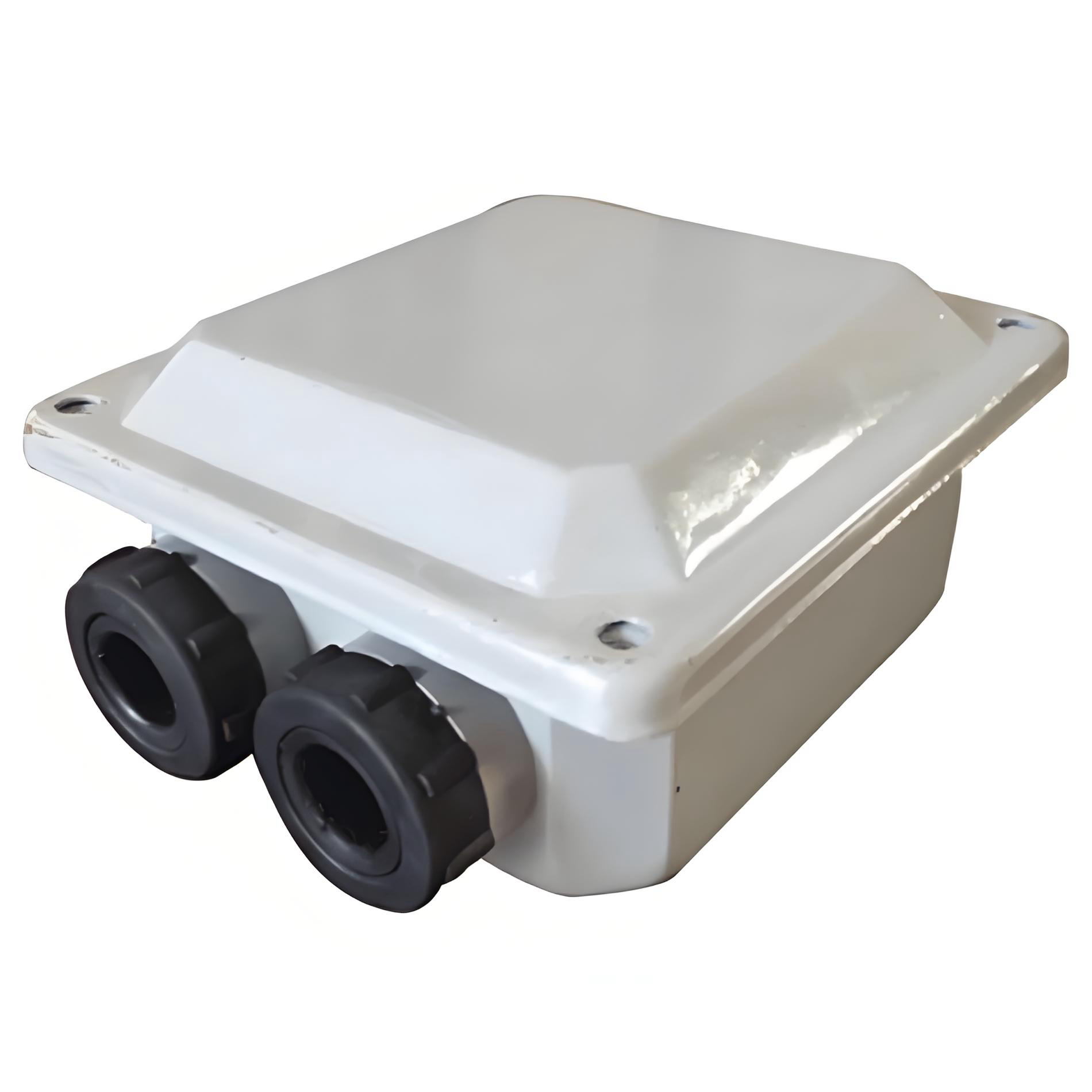

end capIt is an important part mounted on both ends of the motor base, and its main function is toSupport bearings、Protecting the internal structure of the motormergePrevents entry of external contaminants. Simo motor end caps are made ofHigh-strength metal materials和Optimized structural designThis ensures consistent performance in harsh operating environments.

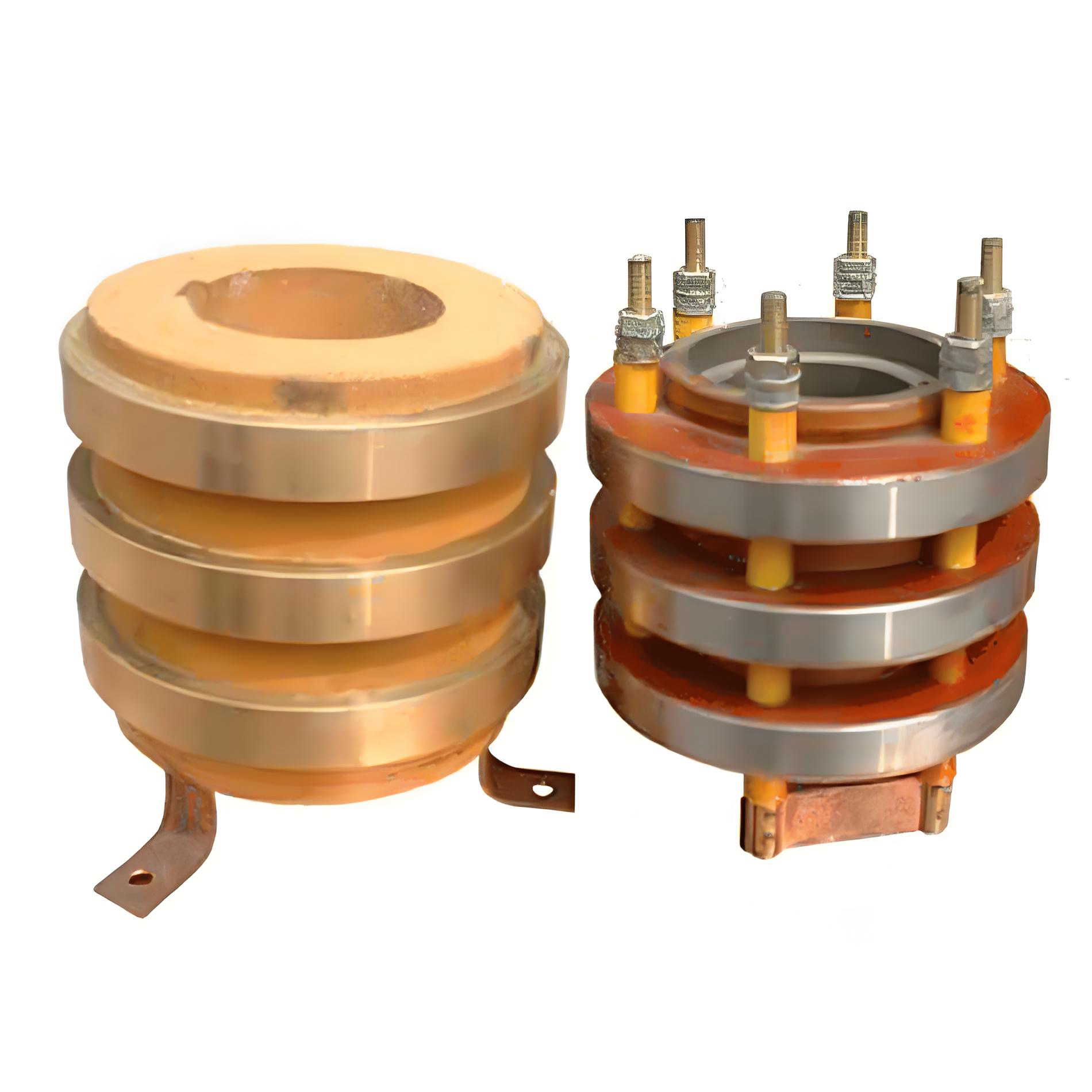

flangelessIt is the motor that is connected to the equipmentinterface componentThe usual features areBolt holes and locating stopsforPrecise alignment和Firmly mounted. Simo motor flange afterprecision machiningThe driver is guaranteed to be compatible with the drive'sa perfect matchThe product is designed to effectively transmit torque and withstand loads.

Simo motor end caps and flanges are available in a wide range depending on the type of motor and application requirements.Specification、Material Selection和InstallationThe company's products are designed to meet the needs of a wide range of applications, from general industrial equipment to special conditions.。

02 Core function: multiple roles to ensure stable operation of the motor

Core function of the end caps

- Bearing support and alignment: ProvidedPrecision bearing chambersThe rotor is positioned accurately to minimize vibration and noise.

- Sealed Protection: CompositionClosed protection structureThe motor is designed to prevent dust, moisture and other contaminants from entering the motor's interior.

- Thermal Aid: Byrational designIncrease the heat dissipation area to assist the internal heat dissipation of the motor.

- structural strengthening: Enhance the overall structural rigidity of the motor to improve shock and vibration resistance.

Core functions of the flange

- device connection: ProvidedStandardized interfacesTo realize the motor and equipmentreliable connection和precise positioning

- power transmission: Transmits motor torque and withstands workloads to ensure efficient power transmission

- Convenient installation:Standardized installation dimensionsStreamline equipment assembly and maintenance processes

- vibration suppression: BySpecial structural designReduced vibration transmission and reduced operating noise

03 Technical characteristics: exquisite craftsmanship to create excellent performance

Simo motor end caps and flanges incorporateAdvanced Design Concepts和Precision manufacturing technologyIt has a number of excellent technical features:

Structural design and material selection

- High-strength materials: The end caps are mainly made ofHigh quality cast iron或aluminumThe flanges are selected according to the application requirementsfoundry iron、steel或aluminumand other materialsThe following are some examples of the types of products that can be used in a variety of applications, ensuring adequate mechanical strength and moderate weight.

- Optimized structural design: Byfinite element analysisOptimized structure to achieve strength whileLightweight designIncrease in power density

- Precision Manufacturing Process: AdoptionCNC machining center和Specialized WorkwearThe key areas such as bearing chambers, stops, etc., are guaranteed to beDimensional accuracy和Form and Position Tolerance

- Surface treatment technology: Providedgalvanized、nickel-plated、blackening processVarious surface treatmentsEnhanced corrosion resistance and aesthetics

Performance Enhancement Technology

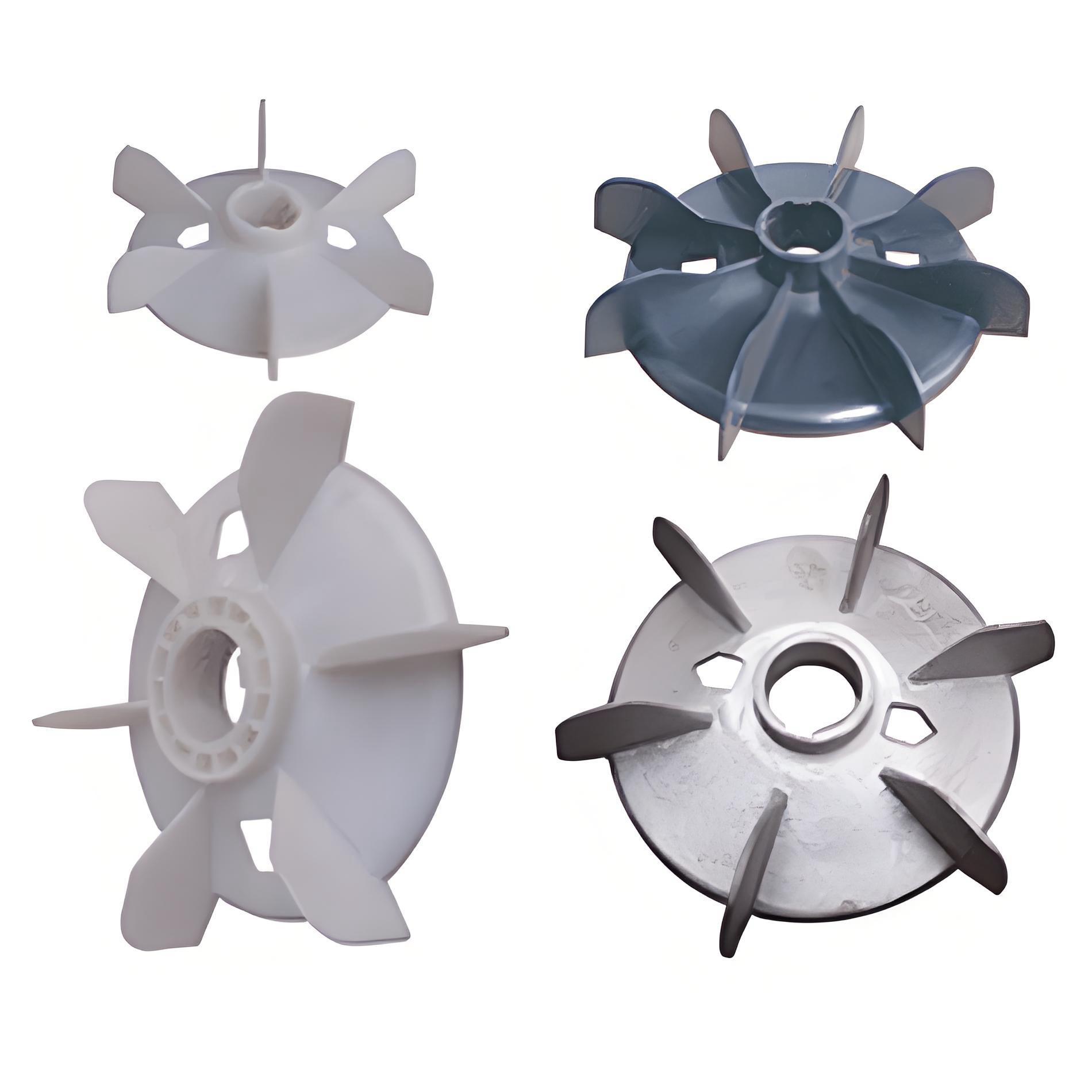

- Dynamic balance correction: Performs on rotating partsPrecision Dynamic BalancingReduces vibration and noise

- Thermal optimization: ByReasonable heat dissipation rib designIncrease heat dissipation area to improve heat dissipation efficiency

- vibration control: ApplicationsVibration suppression technologyReduces noise level and improves smooth motor operation.

- Sealing technology: AdoptionMulti-layer sealing programThis ensures reliable operation of motors in harsh environments.

04 Areas of application: broad adaptability with multi-industry coverage

Simo motor end caps and flanges are characterized by theirreliability performance和Versatile designIt is widely used in many industrial fields:

Industrial General Purpose Fields

- Pumps: Various types of centrifugal pumps, vacuum pumps, submersible pumps, etc., requiring end caps with goodtightness和corrosion resistance

- Fan equipment: Ventilators, induced draft fans, compressors, etc., require end caps withGood dynamic balancecharacterization

- Machine Tools: CNC machine tools, machining centers, milling machines, etc., for flangeConnection accuracy和stiffnessdemanding

Special Application Areas

- Frequency control system: Air-cooledVariable Frequency MotorEnd caps withIndividual ventilation designThis ensures that the motor is available throughout the frequency range of theGood cooling effect

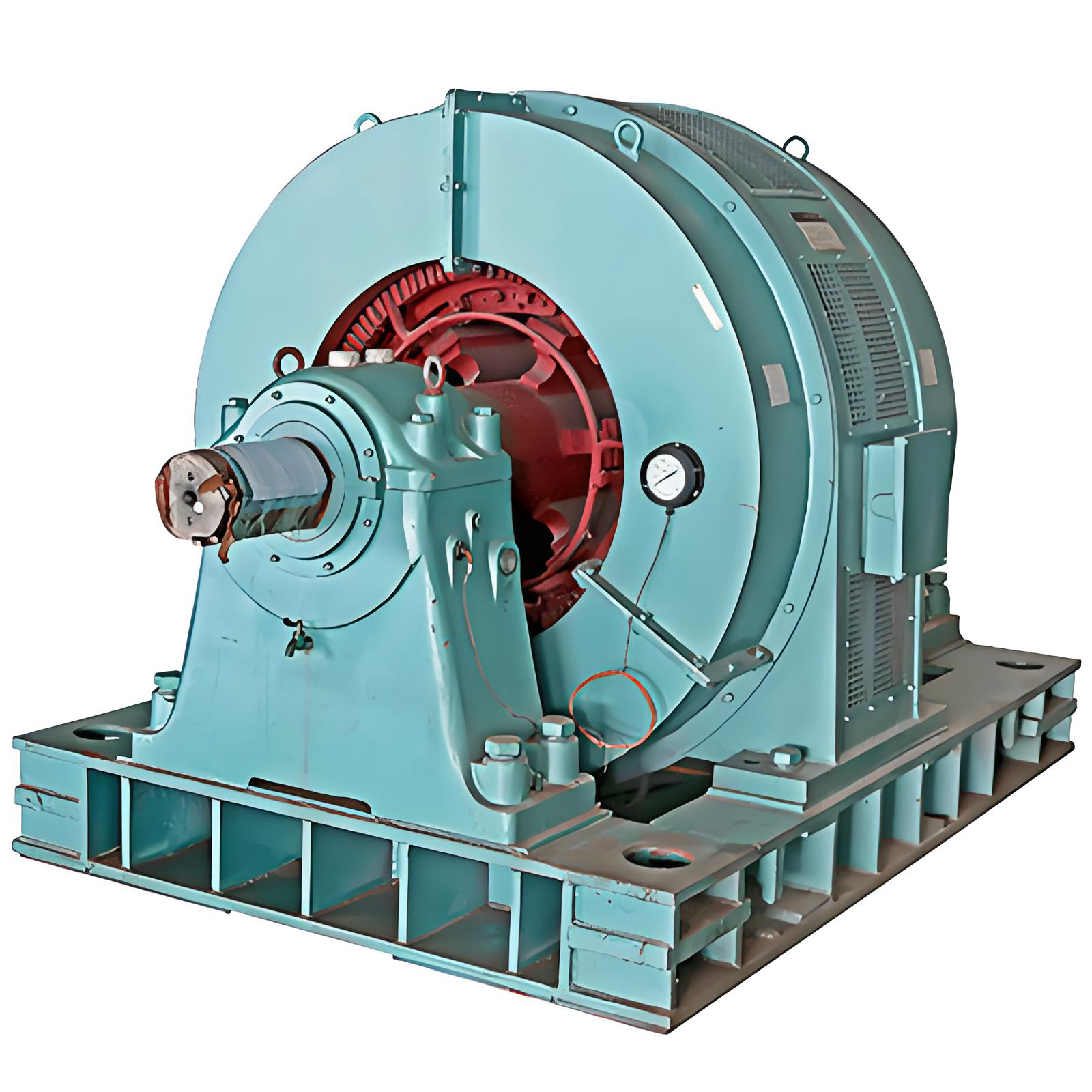

- Heavy machinery and equipment: cranes, rolling mills, crushers, etc., which need to beReinforced end caps and flangesto withstand heavy and shock loads

- rapid transit: Specialized for rail vehiclesMotor End CappossessSpecial structural designfulfillmentdirect-drive motorInstallation Requirements

05 Technical parameters: accurate data to support product selection

Simo motor end caps and flanges cover a wide range of technical specifications to meet the needs of different application scenarios:

Main technical parameters of end caps

Flange main technical parameters

06 Selection Guide: Scientific Selection to Ensure the Best Match

Proper selection is critical to ensure optimum performance of the motor end caps and flanges:

Selection Considerations

- Load Characteristics: Based onWorkload Type(Constant load, variable load, shock load) Selection of suitable end caps and flange configurations

- environmental conditions:: Considerationsenvironmental temperature、humidity level、corrosiveness及Dust conditionsTo determine the appropriate material and level of protection

- mounting space: AssessmentInstallation space limitationsSelection of end caps and flanges of appropriate size and mounting method

- Speed range: Based onWorking speedSelection of the appropriate dynamic balancing class and bearing construction

Selection Procedure

- Determine the motor model: Clarify the motor'smodel number、power (output)、number of revolutions per minute和InstallationBasic information

- Analyze application requirements: Based onapplication scenarioDetermine special requirements for end caps and flanges, such asseal up、radiator、corrosion resistance等

- Reference Standards:: Basisindustry standard和device interfaceSelect end caps and flange types that meet specifications

- Consulting expertise: Recommendations for complex applicationsConsult with Simo's technical teamGet professional selection advice

07 Service support: all-round protection of customer needs

Simo Motors offers full service support for end caps and flange products:

- Specialized technical consulting: Provide technical consulting services on product selection and application solutions

- Customized Solutions: Provided according to customer's special needsPersonalized Design and Manufacturing Services

- Perfect after-sales protection: Provide quality assurance and after-sales service to ensure worry-free use by customers

- Rapid delivery system: EstablishmentEfficient Supply ChainEnsure timely delivery of products

Simo motor end caps and flanges are used as the motor system'sKey structural componentsitssuperior performance和Reliable qualityIt is the basis for ensuring long-term stable operation of the motor. Bycontinuous innovation和Strict quality controlSimo Motors continues to provideQuality products and servicesThe company's products are designed to help all types of machinery and equipment to realize theEfficient and reliableThe power transmission of the

Choosing Simo motor end caps and flanges is choosing theReliable quality assurance和Professional technical supportWe are looking forward to cooperating with you to promote the progress and development of industrial transmission technology. We look forward to cooperating with you to jointly promote the progress and development of industrial transmission technology.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206