Xi'an Sigma YE5 Series Grade 1 Energy Efficiency Super High Efficiency Energy Saving Three-Phase Asynchronous Motors

Date: 2025-12-24 Categories: Industry News Views: 5459

Excerpt:

Breaking through the energy efficiency ceiling: Sigma's YE5 motor reinvents the heart of industrial power Under the dual pressure of the “double carbon” goal and rising energy costs, industrial manufacturing companies are facing unprecedented energy saving challenges. As the “heart” of industrial production, the energy efficiency level of the motor directly determines the operating cost of the entire production line. Traditional inefficient motors have gradually become a black hole that devours profits, and the new generation of XIMA YE5 motors was created to solve this pain point. It is not

Article Catalog[Hidden]

Break through the energy efficiency ceiling:Simo YE5 motorsReinventing the heart of industrial power

Under the double pressure of the “double carbon” target and the continuous rise of energy costs, industrial manufacturing enterprises are facing unprecedented energy saving challenges. As the “heart” of industrial production, the energy efficiency level of the motor directly determines the operating cost of the entire production line. Traditional inefficient motors have gradually become a black hole that devours profits, while the new generation ofSimo YE5 motorsIt was created to address this pain point. It not only represents the currentthree-phase asynchronous motorThe top level of energy efficiency, but also the enterprise to achieve green transformation, cost reduction and efficiency of the key tool.

Redefining “Ultra High Efficiency”: What is the Sigma YE5 Motor?

Simo YE5 motors是Xi'an Simo MotorLtd. has developed and launched the ultra-high efficiency and energy saving three-phase asynchronous motors according to the latest national energy efficiency standard (GB 18613-2020). Compared with the common YE3 and YE4 series in the market, the energy efficiency level of the YE5 series reaches the level defined by the International Electrotechnical Commission (IEC), and the energy efficiency level of the YE5 series reaches the level defined by the International Electrotechnical Commission (IEC).IE5 standard. This means that at the same power outputYE5 motorThe losses are lower and the efficiency of converting electrical energy into mechanical energy reaches a new level.

For companies seeking the ultimate in energy efficiency, theSimo YE5 motorsNot just a piece of equipment, but a long-term energy-saving program. Its core advantage lies in the significant reduction of copper and iron consumption through advanced electromagnetic design and manufacturing process. Whether under rated load or partial load conditions, it can maintain excellent operating efficiency, especially suitable for fans, pumps, compressors and other long-term continuous operation of the load equipment.

Core Technology: Precision Manufacturing for Excellent Performance

In order to achieve ultra-high efficiency at the IE5 level, theSimo YE5 motorsIt has been fully upgraded in terms of material selection and structural design.

- High Quality Cold Rolled Silicon Steel Sheet: Adoption of high-quality cold-rolled silicon steel sheet with low loss and high magnetic conductivity effectively reduces the iron loss of the motor and significantly improves the power factor.

- Insulation system upgradeThe motor adoptsClass F InsulationThe structure, but in the temperature rise assessment in strict accordance with the implementation of Class B standards. This design concept of “high matching and low utilization” greatly improves the reliability and service life of the motor, enabling it to adapt to more severe industrial environments.

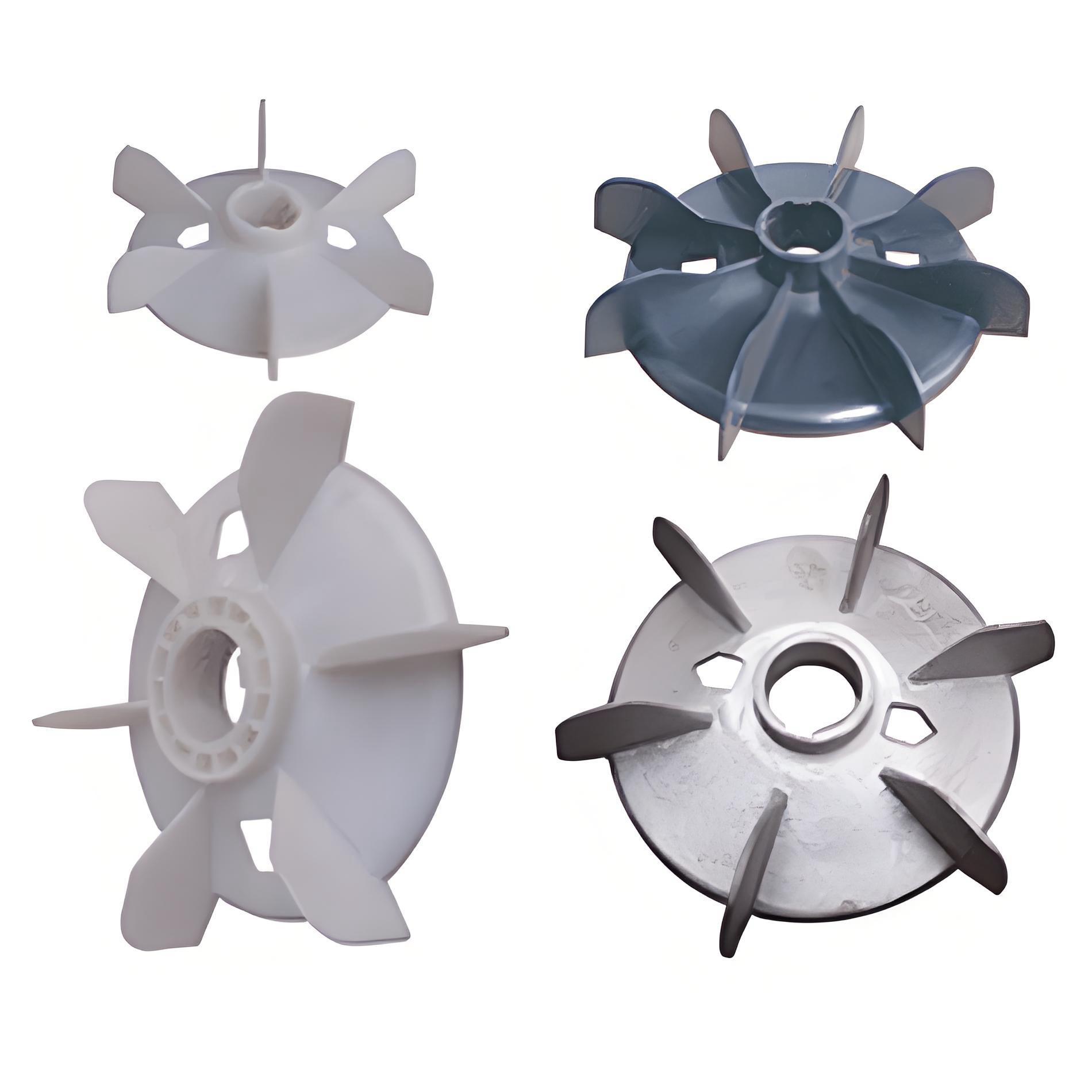

- Optimized cooling system: Totally enclosed self-cooling (IC411) structural design, together with aerodynamically optimized fan and air cover, ensures the heat dissipation effect of the motor under prolonged operation and avoids performance degradation due to overheating.

![[Keywords] [Keywords]](https://simo.org.cn/wp-content/uploads/2025/11/1763968311-124150453.jpg)

Doing the economic math: from “purchase cost” to “full life cycle cost”

Many companies in the procurement of motors, often only focus on the initial purchase price, but ignored the motor full life cycle accounted for a high proportion of 95% or more of the electricity expenses.Simo YE5 motorsAlthough the initial investment is slightly higher than that of a regular motor, its impressive power savings quickly make up the difference.

Case study: chemical plant circulating water pump renovation

As an example, a large chemical plant's circulating water system was retrofitted with an old Y-series motor with a power of 132kW and an annual running time of about 8,000 hours. After an energy efficiency diagnosis, the plant decided to replace it with the same sizeSimo YE5 motors。

- Before renovation: The actual operating efficiency of the old motor is about 90%, with huge annual power consumption and serious heat generation.

- After renovation: Dress UpSimo YE5 motorsAfter that, the measured operating efficiency is increased to more than 96.5%.

- Benefit Measurement: According to the calculation, only this one motor can save about 18,000 kWh of electricity per year. According to the average price of industrial electricity 0.8 yuan / degree calculation, the annual direct savings in electricity expenditure of more than 14,000 yuan.

This means that companies can recoup the investment costs of equipment upgrades in less than two years, and over the subsequent 10-15 year life cycle of the motor, theSimo YE5 motorswill continue to generate pure profit for the business.

Wide range of applications and compatibility

In addition to breakthroughs in energy efficiency, theSimo YE5 motorsThe user's installation convenience is also fully considered. Its installation dimensions fully comply with IEC standards and national standards, and it has good interchangeability with existing ordinary motors. When enterprises carry out energy-saving renovation, they do not need to make large-scale changes to peripheral equipment such as bases and couplings, and can realize seamless replacement, which greatly reduces the difficulty of renovation and downtime.

Currently.Simo YE5 motorsIt has been widely used in petrochemical, electric power, mining, metallurgy and high-end equipment manufacturing. It has not only helped enterprises successfully pass the stringent environmental protection and energy efficiency review, but also won the reputation of the market with stable output and extremely low failure rate in actual production. For those enterprises committed to building green factories and pursuing sustainable development, choosing the YE5 series is undoubtedly an important step towards intelligent manufacturing.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206