Xi'an Xima Motor Fan Blades Genuine Y-Series Motor Cooling Fan

Date: 2025-12-08 Categories: Industry News Views: 8285

Excerpt:

Selection and Maintenance of Xima Motor Fan Blades: The “Heat Dissipation Heart” That Determines Motor Lifespan When industrial motors operate at high speeds, maintenance personnel often focus on bearing, winding, or carbon brush wear, yet frequently overlook a seemingly insignificant yet critical component—the cooling fan blade. As the core of the motor cooling system,

Article Catalog[Hidden]

Simo motorsFan Blade Selection and Maintenance: The “Heat Dissipation Heart” That Determines Motor Lifespan”

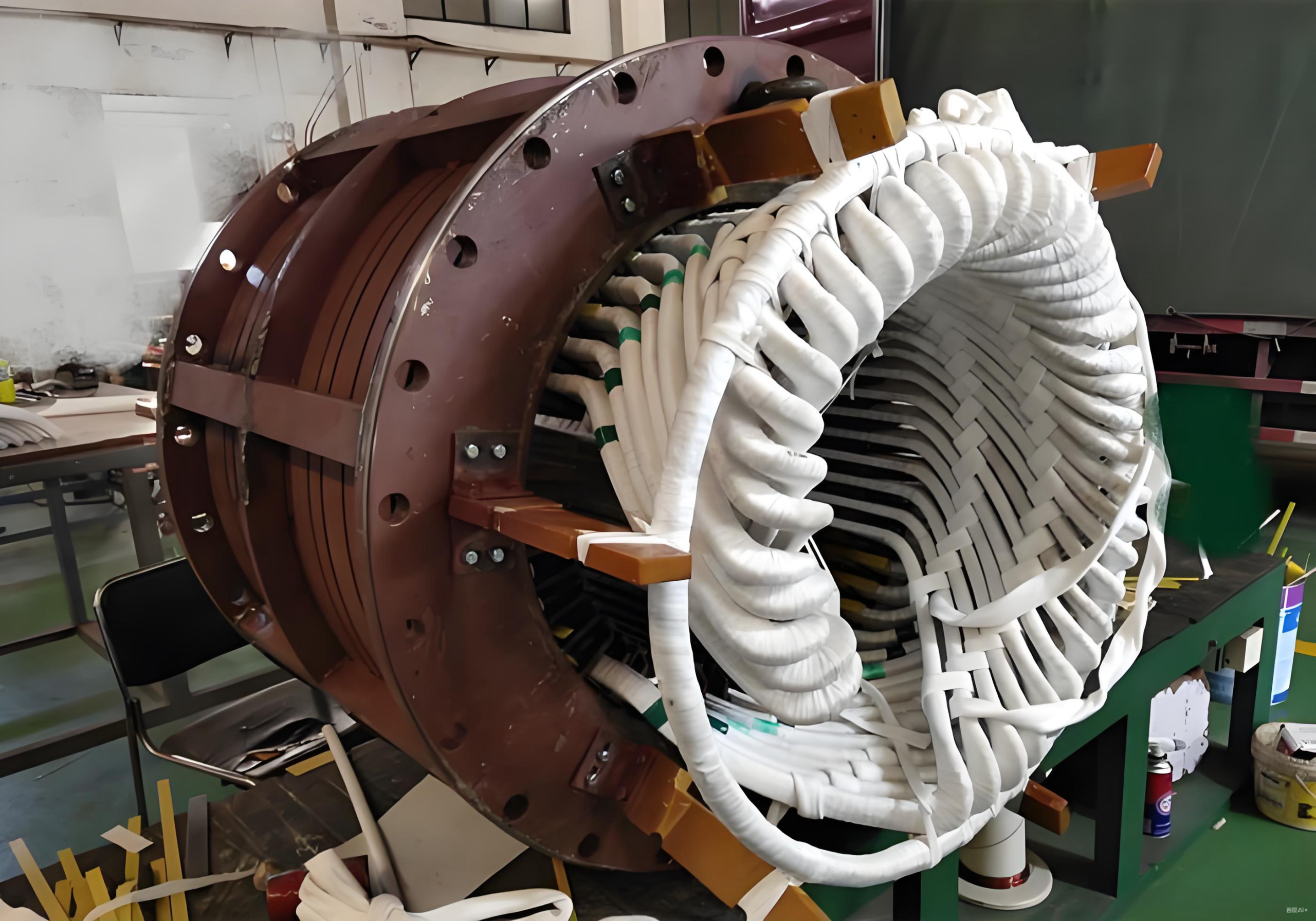

When industrial motors operate at high speeds, many maintenance personnel often focus their attention on bearing, winding, or carbon brush wear, yet they easily overlook a seemingly insignificant yet critically important component—the cooling fan blades. As the core operational unit of the motor cooling system,Simo Motor Wind BladeThe performance of the fan blades directly determines whether the motor can operate stably at its rated temperature. Once the blades become damaged or are incorrectly sized, the resulting high temperatures will become an “invisible killer” that shortens the motor's lifespan.

OEM Compatibility: More Than Just the Right Size

In the motor accessories market, many users hold the misconception that any fan blade can be used as a replacement as long as the inner bore diameter and outer diameter match. However, for brand motors like SIMO that demand extremely high manufacturing precision, this practice carries significant risks.

Simo Motor Wind BladeDuring the initial design phase, rigorous fluid dynamics calculations were performed based on the heat output, aerodynamic resistance curve, and rotational speed of specific motor models.The blade angle, curvature, and number of blades in the original factory fan have all been precisely calibrated to achieve the optimal airflow and pressure ratio. If generic, low-quality fan blades are used indiscriminately, even if they can be installed, they may cause the motor to overheat rapidly due to insufficient airflow or trigger severe motor vibration due to poor dynamic balance, ultimately damaging the front and rear end covers and bearings.

The Importance of Material Craftsmanship and Dynamic Balancing

High-quality motor fan blades are not merely about shaping; they also involve the application of materials science. Depending on the motor's intended use,Simo Motor Wind BladeTypically categorized into cast aluminum, reinforced engineering plastics, and steel plate welded constructions, among other materials.

- Cast Aluminum Fan BladeCommonly found in high-voltage, high-power motors, it features high strength, resistance to deformation, corrosion resistance, and excellent heat dissipation properties.

- Engineering Plastic Fan BladePrimarily used in small and medium-sized low-voltage motors, it offers advantages such as light weight, low rotational inertia, and low noise.

Regardless of the material,Dynamic Balancing TestThese are all mandatory procedures before leaving the factory.If the center of gravity of the fan blades shifts, the centrifugal force generated by the motor during high-speed rotation will increase exponentially, resulting in excessive noise levels.

Case Study: Malfunction Caused by Improper Fan Blade Selection

In a case study of equipment maintenance at a chemical plant, a Xima Z4DC motorAn abnormal high-temperature alarm was triggered. During an initial inspection, maintenance personnel discovered a broken blade on the original fan. They promptly procured a generic replacement fan blade of similar dimensions for installation.

After running for less than a week, the motor shut down again due to overheating, accompanied by a distinct low-frequency humming noise. Professional inspection and analysis revealed the issue stemmed from the newly installed fan blades: due to the non-branded blades'The blade pitch is too small.At the same rotational speed, the effective cooling airflow produced is only a fraction of the original factory specification.Simo Motor Wind BladeThe 60% was simply unable to dissipate the heat generated by the DC motor under high load. Ultimately, the factory reordered the original manufacturer's parts, and the motor temperature promptly returned to normal, with the vibration disappearing as a result.

How to Properly Measure and Replace

To ensure the correct parts are procured, when replacingSimo Motor Wind BladeWhen verifying, it is recommended to follow these three key steps:

- Verify shaft bore dimensions and keywayThis is the foundation for installation, requiring millimeter-level precision and confirmation of whether a flat key or a half-round key is used.

- Verify the outer diameter and height of the fan bladesAn excessively large outer diameter may cause friction with the air duct cover, while an excessively small diameter will reduce airflow efficiency.

- Check the number and material of the blades: Maintain consistency with the original machine as much as possible, unless there are specific requirements for noise reduction or anti-corrosion upgrades.

![[Keywords] [Keywords]](https://simo.org.cn/wp-content/uploads/2025/11/1764030612-85656.jpg)

When installing the fresh air fan, be sure to clean rust and burrs from the shaft extension.Never strike with a heavy hammer.To prevent cracking of the fan blade bore or deformation of the motor shaft, it is recommended to heat the shaft bore appropriately before performing a hot-fit installation for large-sized cast aluminum fan blades. This approach is both more scientific and safer.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206