Comprehensive Analysis of Motor Slip Rings: Working Principles, Application Scenarios, and Maintenance Guide

Date: 2025-12-08 Categories: Faq Views: 7758

Excerpt:

Unveiling Core Components: Solving Rotational Conductivity Challenges with Premium Motor Slip Rings In the highly automated era of Industry 4.0, countless mechanical devices—from radar antennas performing omnidirectional scans to wind turbine blades in rotation—require continuous 360-degree power and signal transmission. Have you ever wondered how these systems avoid the persistent issue of cable entanglement?

Article Catalog[Hidden]

Unveiling the Core Component: Solving Rotating Electrical Conductivity Challenges with Premium Motor Slip Rings

In the highly automated era of Industry 4.0, from the omnidirectional scanning of radar antennas to the rotating blades of wind turbines, countless mechanical devices require continuous 360-degree rotation while transmitting power and signals. Have you ever wondered how these systems avoid the critical issue of cable entanglement? The answer lies hidden within a seemingly unremarkable yet crucial precision component—Motor slip ringIt serves not only as the bridge connecting rotation and stillness, but also as the “heart” ensuring the stable operation of the entire electromechanical system.

What Are Motor Slip Rings and Their Core Value

Motor slip ringAlso known as conductive slip rings, collector rings, or rotating electrical interfaces. Their fundamental function is to establish one or more continuous, reliable transmission channels between two relatively rotating mechanisms.

This is akin to building an uninterrupted bridge on a rotating stage. For high-end equipment,Slip rings are not merely tools for transmitting electrical current; they also serve as conduits for low-voltage signals, video data, and even high-frequency signals. If slip rings fail to meet quality standards, they may cause signal transmission packet loss and image flickering at best, or sparking and burn out expensive control systems at worst. Therefore, selecting high-quality slip rings is the first step to ensuring long-term, trouble-free operation of equipment.

Key Considerations for Selection: More Than Just Size Compatibility

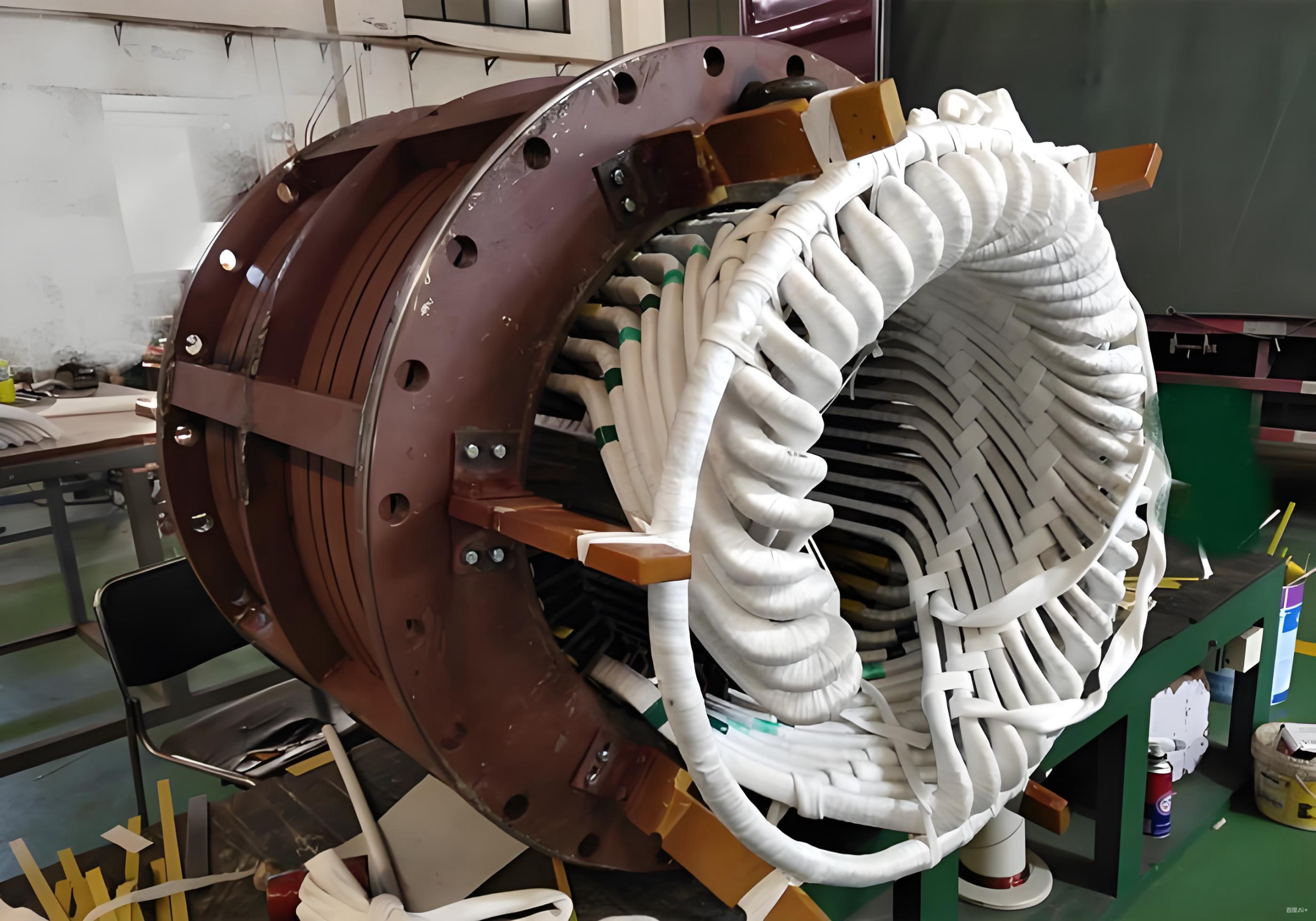

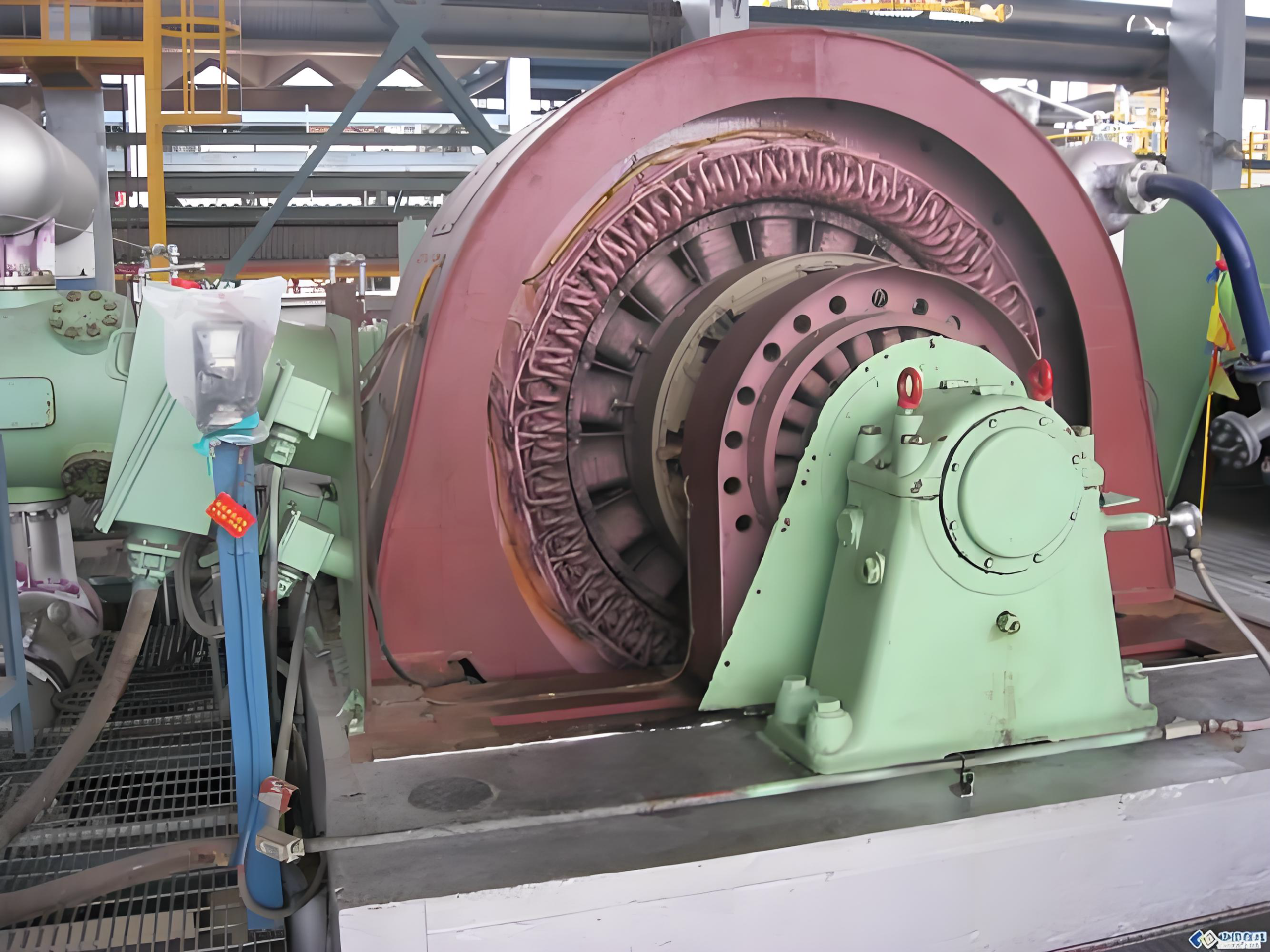

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2023/08/1763892530-3543-scaled-e1763892798564.png)

Many procurement personnel or junior engineers often focus solely on the bore diameter and number of passages when selecting slip rings, while overlooking more critical performance parameters. To ensureMotor slip ringTo ensure the longevity and stability of the system, the following dimensions must be taken into consideration:

-

Operating Speed and Contact Materials:

Rotational speed determines the friction heat and wear rate of the contact points inside the slip ring. For high-speed rotating motors, slip rings with higher wear resistance must be used.Precious metal alloy contacts(such as gold-gold contact), rather than ordinary copper-graphite materials.Gold-Gold Contact TechnologySignificantly reduces contact resistance, ensuring an extremely low bit error rate during microamp-level signal transmission.

-

Protection Rating and Application Environment:

Not all slip rings are suitable for harsh environments. If equipment is deployed in humid, dust-intensive outdoor settings—such as construction machinery or port cranes—it is essential to select slip rings with an IP rating of at leastIP65Even higher-end products.

-

Anti-interference design:

When power sources (high-voltage circuits) and sensor signals (low-voltage circuits) are transmitted within the same slip ring, electromagnetic interference (EMI) poses a significant challenge. High-quality slip rings incorporate additional shielding between high-voltage and low-voltage circuits.Dedicated shielding layerPhysically isolate interference sources to ensure the purity of data transmission.

Case Study: Breaking Through Efficiency Barriers in Automated Packaging Lines

To gain a more intuitive understandingMotor slip ringTo illustrate its importance, let's examine a real-world case. A large food processing plant once faced a challenging issue: the rotating sealing station of its high-speed automated packaging machine frequently experienced erratic temperature sensor signals. This led to inconsistent sealing temperatures, resulting in a product defect rate as high as 51%.

Technical investigation revealed that the original low-end carbon brush slip rings generated significant carbon powder buildup during high-speed rotation, resulting in degraded insulation performance and signal crosstalk.

Solution:

The factory replaced the original components with custom-made ones.Fiber-Optic and Electromagnetic Hybrid Slip RingThis solution not only upgrades the conductive contacts toFiber Brush Technology(Fiber Brush Technology) enables maintenance-free operation and resolves air path rotary sealing issues through integrated channels.

Result:

After replacement, the equipment operated continuously for six months without failure, with the defect rate dropping below 0.11%. Maintenance costs were reduced by 80%. This case clearly demonstrates that a suitable slip ring solution can directly translate into production efficiency gains.

Maintenance and Care: The Secret to Extending Lifespan

Although modern technology has produced numerous “maintenance-free” slip rings, regular inspections remain essential. For contact-typeMotor slip ringThe most common failures stem from oxidation or the accumulation of wear debris on contact surfaces.

- Regular cleaningUse dry compressed air to clean dust around the slip ring to prevent contaminants from entering the rotating gap.

- Monitoring ParametersRegularly measure the dynamic contact resistance using a multimeter. If significant fluctuations in resistance are detected, this typically indicates contact wear or spring fatigue, necessitating prompt replacement.

Only by deeply understanding the “temperament” of slip rings can this rotating “heart” keep beating powerfully and continuously, providing uninterrupted momentum and data support for smart manufacturing.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206