Sima Motor Slip Rings and Collector Rings: Genuine OEM Parts Directly from Stock

Date: 2025-12-10 Categories: Industry News Views: 2606

Excerpt:

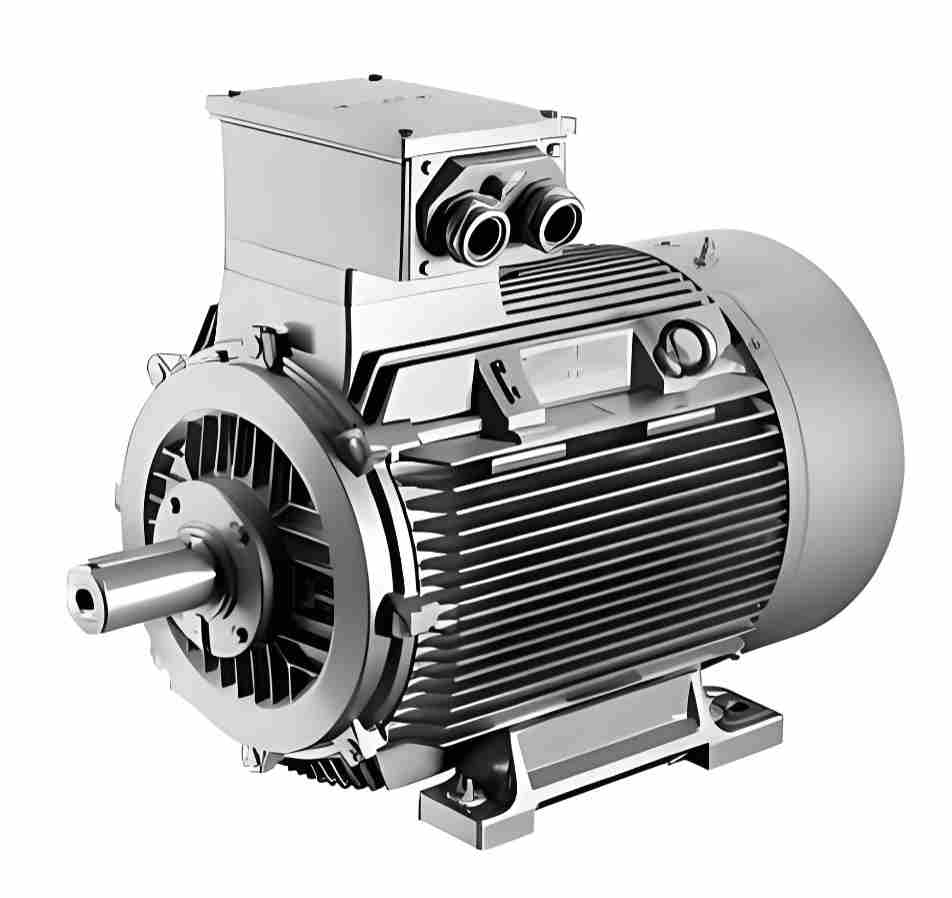

In industrial drive systems, large high-voltage motors often serve as the “heart,” yet the slip rings—critical components for pacemaker function—are frequently overlooked due to their small size. In reality, the operational status of Xima Motor slip rings (also known as collector rings) directly determines the torque output stability and service life of wound-rotor motors. Many factories only become aware of the issue when encountering severe motor sparking and overheating.

Article Catalog[Hidden]

In industrial drive systems, large-scaleHigh voltage motorsOften serving as the “heart” of the device, the conductive ring—a critical component for cardiac pacing—is frequently overlooked despite its small size. In fact,Simo motorsslip ringThe operational status of slip rings (also known as collector rings) directly determines the torque output stability and service life of wound motors. Many factories only realize the immense material science and precision machining demands behind these seemingly simple copper rings when faced with severe motor sparking and overheating. This article will delve into the technical value and maintenance strategies for this core component.

Core Process: Why Genuine Parts Matter

In the market, various universal slip rings abound, but for users of Xima brand motors, selecting the original manufacturer's specifications is essential.Simo Motor Slip RingsIt serves as the first line of defense in ensuring closed-loop system safety. This is not merely a matter of dimensional compatibility but also involves considerations of material compatibility.

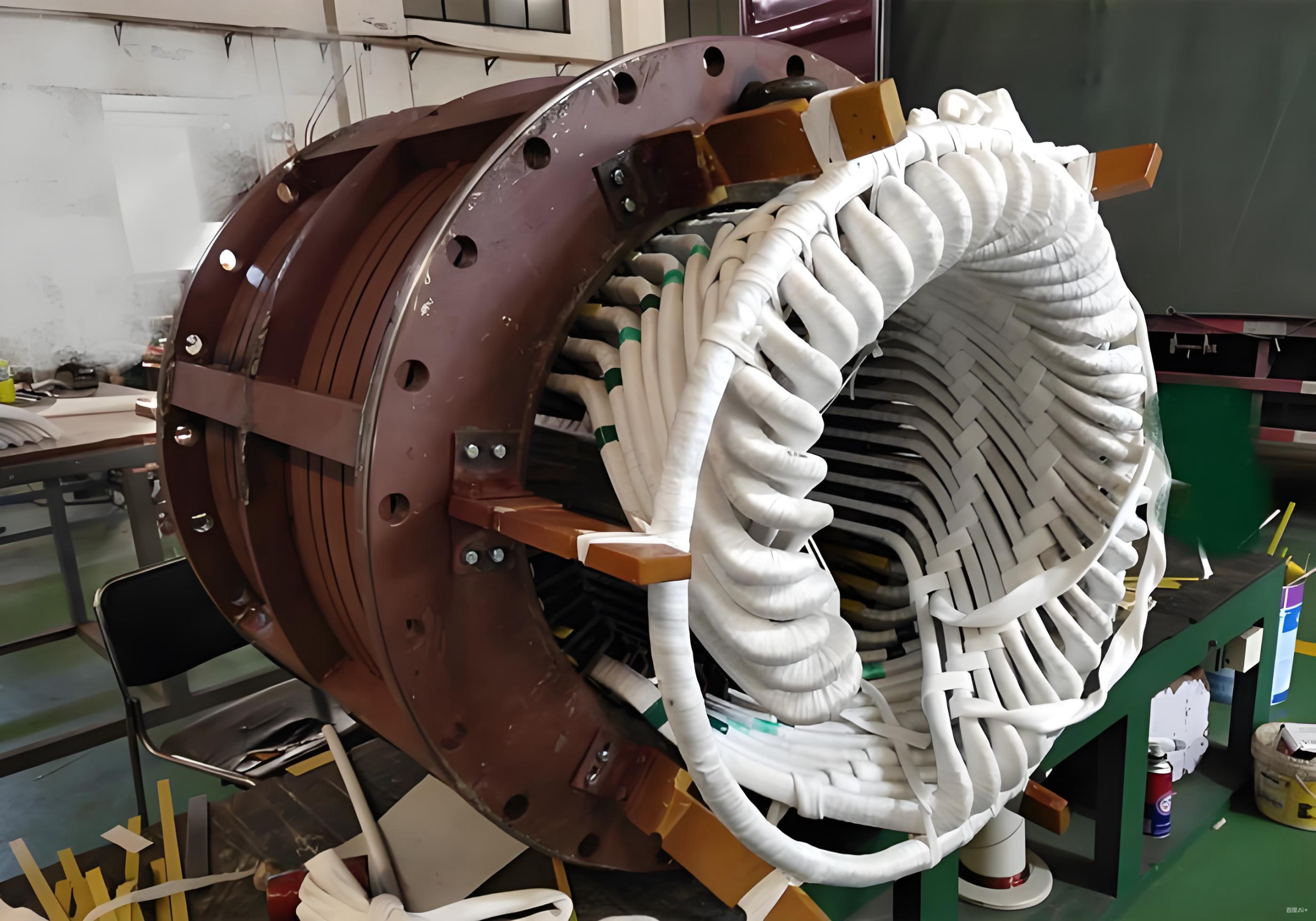

High-quality slip rings typically employSpecial wear-resistant copper alloy or forged steelManufactured with extremely low resistivity and superior thermal conductivity. Unlike commercially available imitations with inconsistent hardness, slip rings produced through standardized processes form a perfect “oxide film” with carbon brushes during high-speed rotation. This imperceptibly thin film is crucial for reducing friction losses and preventing brush sparking. Using inferior substitutes often leads to fluctuations in the motor rotor's excitation current, potentially causing burnout.brush holder。

Operation and Maintenance: How to Extend Slip Ring Lifespan

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2025/11/1764030612-85656.jpg)

Even the highest qualitySimo Motor Slip RingsWithout proper maintenance, optimal performance cannot be achieved. In practical applications, engineers should focus on the following maintenance dimensions:

- Concentricity MonitoringThe radial runout of the slip ring after installation must be controlled within the specified range. Excessive runout will cause unstable contact between the carbon brush and the ring surface, resulting in mechanical sparks.

- Surface Condition InspectionA healthy slip ring surface should exhibit uniformreddish brown or dark blueLuster (oxidation film). If grooves, burn marks, or oil stains appear on the surface, grinding or turning must be performed promptly.

- Ventilation and heat dissipationDue to the generation of Joule heating during slip ring operation, ensuring clean ventilation within the collector chamber is critical, as carbon deposits and dust are the primary causes of short circuits.

Case Study: The Story of Cooling Down Motors at a Rolling Mill

To illustrate the importance of proper accessory selection more clearly, let's examine a real-world maintenance case. At a large steel mill, a ZR series XimaWire-wound motorsAfter prolonged operation under high loads, frequent overheating alarms occurred in the slip ring chamber, with temperatures soaring above 120°C accompanied by noticeable ring fire phenomena.

The maintenance team initially attempted replacing the carbon brushes with different brands, but the problem persisted. After disassembling and inspecting the motor, it was discovered that a non-original slip ring had been previously installed. Due to its...Material hardness is excessively high and ovality exceeds specifications.This causes the carbon brush to undergo high-frequency vibration during high-speed friction, resulting in a sharp increase in contact resistance.

The solution was very clear: the team repurchased and installed genuine products.Simo Motor Slip RingsAfter 24 hours of operation, monitoring data showed the slip ring surface temperature stabilized at approximately 75°C, with sparks completely eliminated. The equipment resumed efficient and stable operation. This case clearly demonstrates that in precision motor systems, the compatibility of core components must never be compromised.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206