The new national standard YE5 motor: first-class energy efficiency to help enterprises realize green energy saving and consumption reduction

Date: 2025-12-05 Categories: Company News Views: 6363

Excerpt:

The New Peak of Industrial Energy Efficiency: In-depth Analysis of the Energy Saving Revolution Brought about by YE5 Motors Under the dual background of today's “dual-carbon” goal and the continuous rise in energy costs, the logic of survival for industrial enterprises is undergoing profound changes. For many manufacturing companies, the motor system consumes nearly 70% of the plant's electricity, which means that every small improvement in motor energy efficiency can be directly translated into considerable profit growth. ye5 motor is the new peak of industrial energy efficiency.

Article Catalog[Hidden]

New Heights in Industrial Energy Efficiency: An In-Depth AnalysisYE5 motorThe Energy-Saving Revolution It Brings

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2025/11/1764029149-23358.jpg)

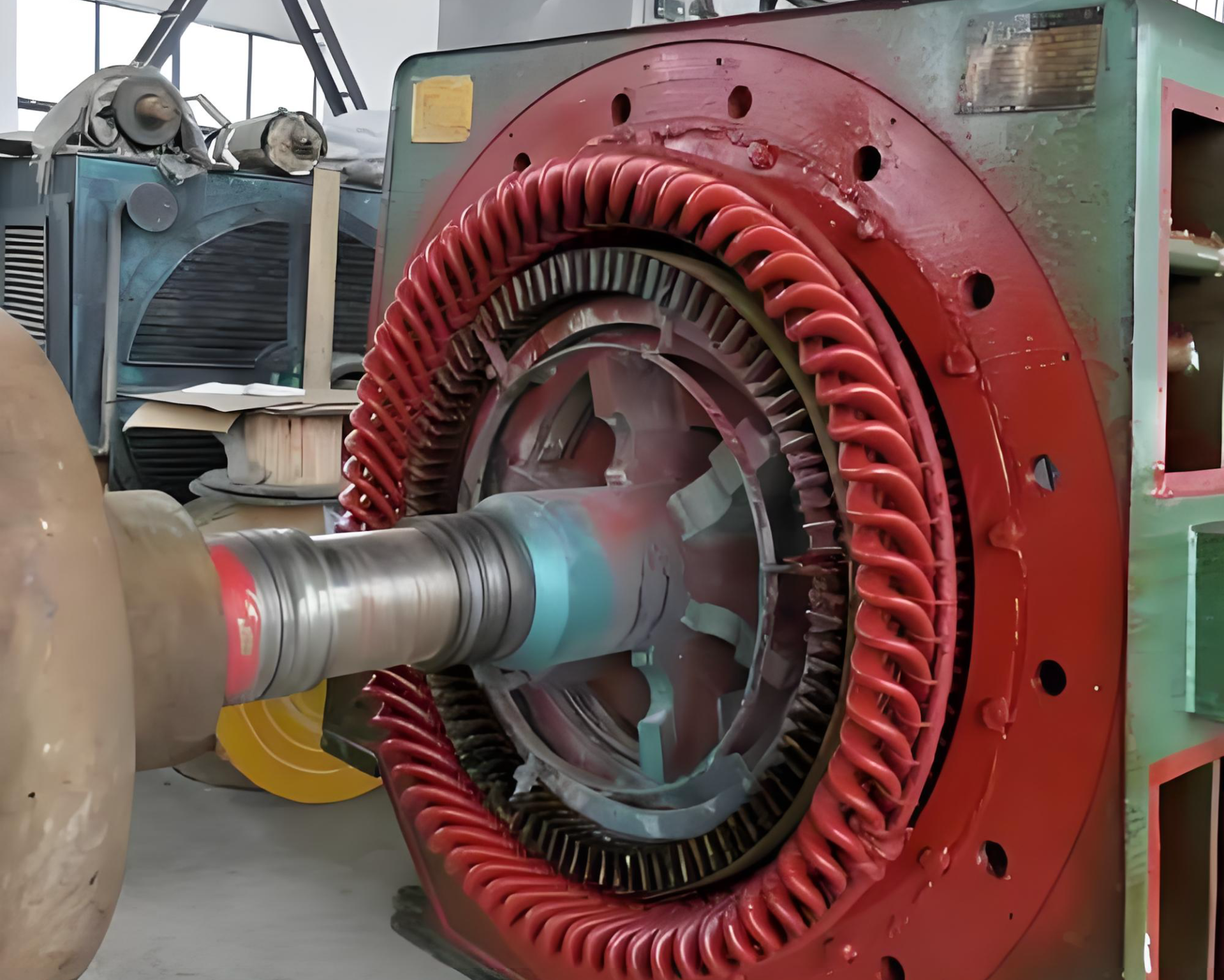

Against the dual backdrop of today's “dual carbon” goals and persistently rising energy costs, the survival logic of industrial enterprises is undergoing profound changes. For many manufacturing companies, motor systems consume nearly 70% of the plant's total electricity. This means that every incremental improvement in motor energy efficiency can directly translate into substantial profit growth.YE5 motorAs a Class 1 energy efficiency product defined in the current national standard GB 18613-2020, it is progressively replacing outdated models to become the preferred engine for industrial green upgrades. Not only does it represent the pinnacle of motor technology, but it also serves as a crucial tool for enterprises to achieve cost reduction and efficiency gains.

What is a YE5 motor?

YE5 motor refers toSuper-super-efficientthree-phase asynchronous motorIts energy efficiency indicators comply with the International Electrotechnical Commission (IEC) standards.IE5 compatibility levelCompared to the commonly available YE3 (IE3) and YE4 (IE4) motors on the market, the YE5 employs a more advanced electromagnetic design, higher-quality silicon steel laminations, and optimized manufacturing processes. This significantly reduces iron losses, copper losses, and mechanical losses during motor operation.

In short, the YE5 motor is the energy-saving champion in today's industrial motor field.

Core Advantage: More Than Just Energy Savings

When selecting equipment, companies often focus on initial procurement costs, but total lifecycle cost (LCC) is the true determinant of profitability. The advantages of YE5 motors are evident in the following dimensions:

- Ultimate energy-saving performanceBased on actual measurement data, the average efficiency of the YE5 motor is higher thanYE3 motorApproximately 21% higher than 3T-3%. While the numerical difference may seem small, in industrial scenarios operating 24/7, this efficiency gap will translate toCompound Interest EffectGenerate significant savings on electricity bills.

- More stable operation, longer service lifeDue to reduced losses, the YE5 motor exhibits significantly lower temperature rise during operation compared to conventional motors.Low temperature riseThis means the aging rate of the insulation system slows down, extending the service life of bearings and significantly reducing maintenance costs for enterprises as well as the risk of downtime caused by equipment failures.

- Highly compatible, easy to replaceYE5 motors produced by reputable manufacturers typically adhere to standard installation dimensions (such as frame size, shaft diameter, etc.), meaning enterprises should follow these specifications when installing them.Energy-saving technical upgradesSeamless replacement can be achieved without modifying the original equipment base or transmission structure.

Case Study: A Chemical Plant's Financial Transformation

To more clearly demonstrate the economic benefits of YE5 motors, we present the case study of a circulating water pump system upgrade at a chemical plant in Jiangsu Province. The facility originally operated 10 YE3 motors with a power rating of 55kW each, running approximately 8,000 hours annually. Industrial electricity rates were calculated at 0.75 yuan per kilowatt-hour.

Replacing all 10 motors withYE5 Ultra-High-Efficiency MotorAfter one year of operational monitoring, it was found that:

- The average operating current of each motor has decreased, saving approximately 1.5 kWh of electricity per hour.

- Annual electricity savings per unit: 1.5 kWh × 8,000 hours = 12,000 kWh.

- Annual electricity cost savings across the entire system12,000 degrees × $0.75 × 10 units = 90,000 yuan。

Although the procurement cost of YE5 motors is slightly higher than that of YE3 motors, the company recouped the entire price difference in less than a year solely through electricity cost savings. Over the motor's 10- to 15-year service life, the subsequent savings amounting to hundreds of thousands of yuan translate into pure profit.

How to Properly Select a YE5 Motor?

With the explosive growth in market demand, the motor industry has become a mixed bag of brands. Companies should exercise caution and discernment during procurement:

- Verify energy efficiency labelsEnsure that the product nameplate clearly states “Class 1 Energy Efficiency” and the applicable standard GB 18613-2020.

- Monitor temperature rise dataHigh-quality YE5 motors typically feature F-class or H-class insulation but are tested to B-class temperature rise standards, indicating superior overload capacity.

- Field visitFor bulk purchases, it is recommended to inspect the manufacturer's production and testing equipment. Only factories with high-precision machining capabilities can produce YE5 motors that meet strict tolerance requirements.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206