YXKS High Voltage Motor Manufacturer Sigma Motor Efficient Drive

Date: 2026-01-24 Categories: Industry News Views: 8148

Excerpt:

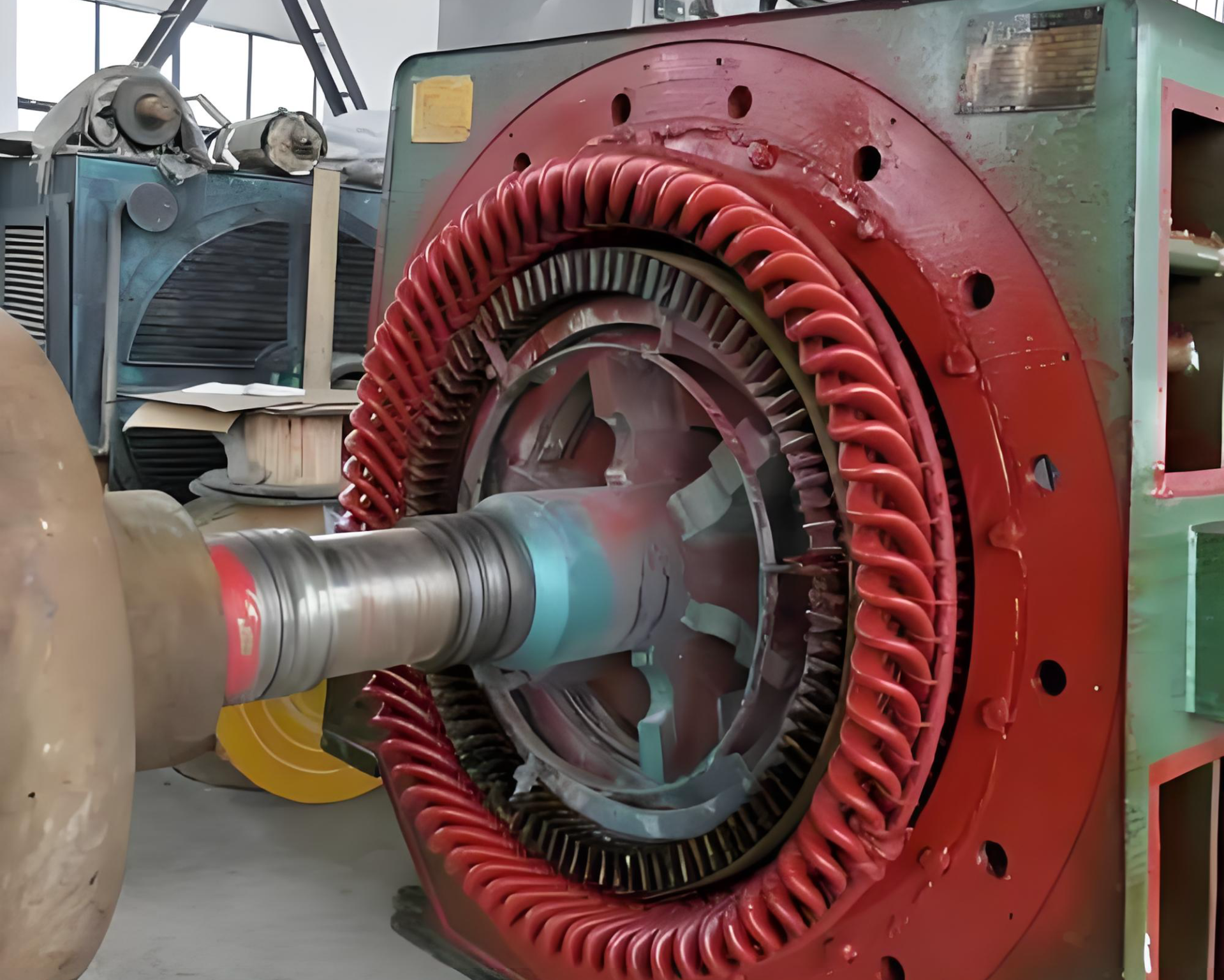

SIMOTEC is a professional manufacturer of high voltage motors and is committed to providing customers with efficient drive solutions.The YXKS series of high voltage motors are widely used in many industrial fields, and the following are their main features and advantages:1. High EfficiencySIMOTEC's YXKS high voltage motors are characterized by high efficiency with the use of advanced design and high-quality materials, which can effectively reduce the energy consumption and improve the overall efficiency of the system.2

Article Catalog[Hidden]

Simo motors(SIMOTEC)是一家专业生产High voltage motors的制造商,致力于为客户提供高效的驱动解决方案。YXKS系列高压电机在多个工业领域中得到了广泛应用,以下是其主要特点和优势:

1. 高效能

西玛电机的YXKS高压电机采用先进的设计和优质材料,具有高效能的特点,能有效降低能耗,提高系统的整体效率。

2. 稳定性与可靠性

![[Keywords] [Keywords]](https://simo.org.cn/wp-content/uploads/2025/11/1763978462-986633.png)

YXKS系列电机的结构设计注重稳定性,能够在恶劣环境下持续运行,降低故障率,确保生产的连续性和安全性。

3. 适用广泛

高压电机可广泛应用于化工、矿业、冶金、水泥等行业,满足各种复杂的工业驱动需求。

4. 先进的技术

西玛电机不断创新,采用最新的电机技术和制造工艺,确保产品的高性能和长寿命。

5. 定制化服务

针对不同客户的具体需求,西玛电机提供定制化服务,帮助客户设计和选择最适合的电机解决方案。

6. 优质的售后服务

西玛电机为客户提供全面的售后服务支持,确保客户在使用产品过程中获得及时的技术支持和维护服务。

如需了解更多关于YXKS高压电机的信息或者获取具体的产品资料,建议访问西玛电机的官方网站或直接联系其客户服务团队。无论是在性能、效率还是服务支持方面,西玛电机都将为您提供最优质的产品与服务。

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206