National Standard YE2 Motor High-Efficiency Energy-Saving Three-Phase Asynchronous Motor Manufacturer Direct Sales

Date: 2025-12-07 Categories: Faq Views: 2522

Excerpt:

In-Depth Analysis of YE2 Motors: The Cost-Effective Choice for Industrial Power Systems Within the vast landscape of modern industrial production, the stability of power systems directly determines a company's production efficiency and operational costs. As the core driving force behind mechanical equipment, YE2 motors (the YE2 series of high-efficiency three-phase asynchronous motors) have become the preferred choice for numerous manufacturing enterprises and equipment suppliers due to their exceptional reliability and outstanding cost-effectiveness.

Article Catalog[Hidden]

YE2 MotorIn-Depth Analysis: The Cost-Effective Choice for Industrial Power Systems

Within the vast landscape of modern industrial production, the stability of power systems directly determines a company's production efficiency and operational costs. As the core heart driving mechanical equipment,YE2 Motor(i.e., the YE2 series high-efficiency)three-phase asynchronous motorWith its outstanding reliability and exceptional cost-effectiveness, the YE2 motor has become the preferred choice for numerous manufacturing enterprises and equipment suppliers. Understanding and correctly applying the YE2 motor within the vast and diverse motor market represents a critical challenge that every equipment engineer and procurement manager must master.

What is a YE2 motor?

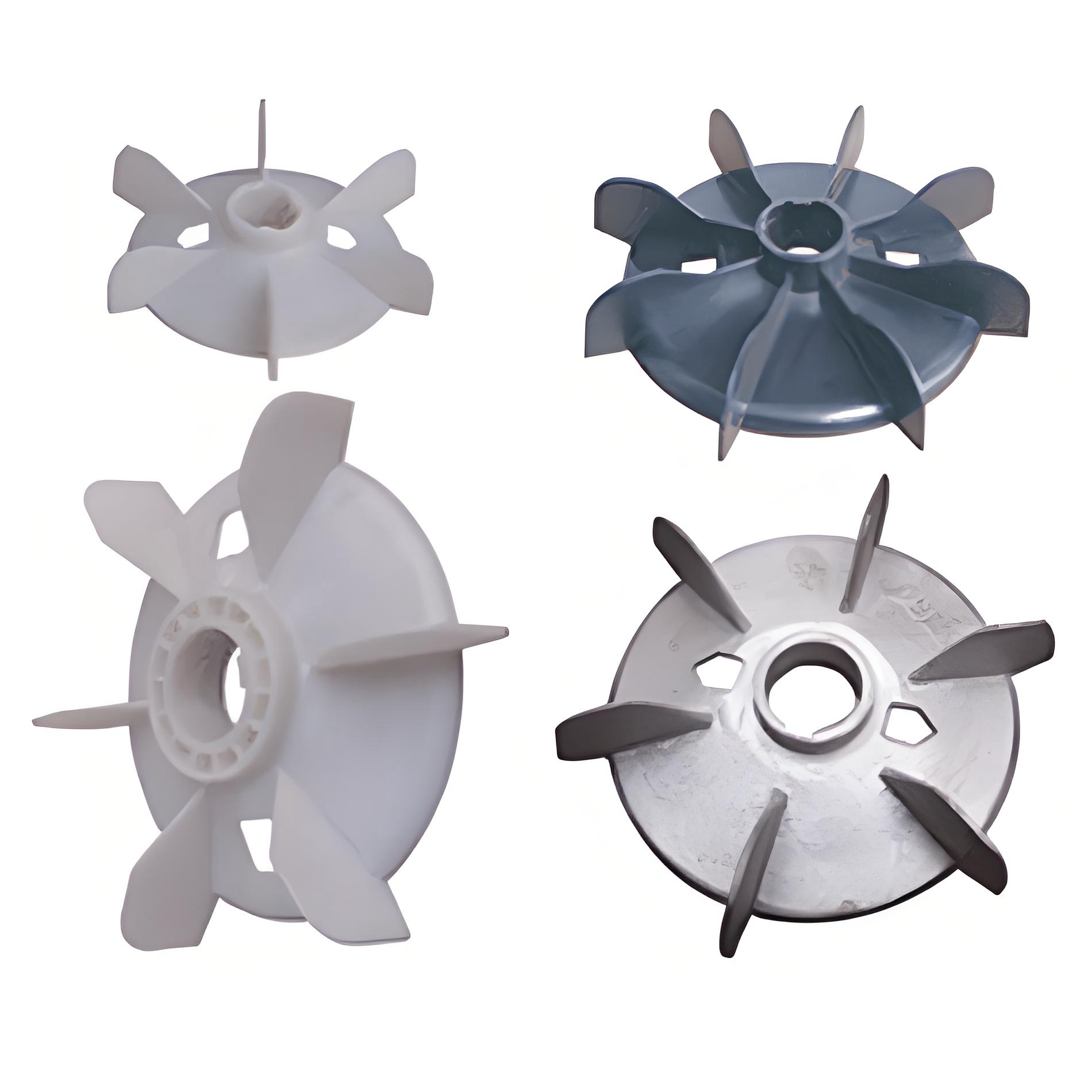

YE2 MotorYE2 is the abbreviation for fully enclosed, self-ventilated squirrel-cage three-phase asynchronous motors. From a technical standards perspective, it corresponds to the IE2 energy efficiency class in the International Electrotechnical Commission (IEC) standards and also meets the energy efficiency limit values specified in the Chinese national standard GB 18613-2012. As the upgraded successor to the Y and Y2 series motors, the YE2 was positioned as the “industrial standard power” from its initial design phase.

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2025/11/1764033560-34342.jpg)

Compared to older models, the YE2 motor features an optimized electromagnetic design and utilizes cold-rolled silicon steel sheets with higher magnetic permeability, effectively reducing copper and iron losses. This means that at equivalent power output,YE2 MotorDelivering more powerful output with less heat loss enables the realization of factoryEnergy Conservation and Consumption Reductionfoundational hardware.

Core Strength: Balancing Cost and Performance

In industrial applications, while pursuing ultimate energy efficiency (such as YE3 and YE4) is undoubtedly a trend, in many general-purpose scenarios,YE2 Motordemonstrated irreplaceable comprehensive strengths:

- Exceptionally high value for moneyFor conventional equipment with frequent starts and minimal load variations, the procurement cost of YE2 motors is significantly lower than that of super-efficient motors, enabling enterprises to achieve a notably shorter return on investment (ROI).

- Outstanding versatilityThis series of motors adopts internationally standardized dimensions, with mounting dimensions compliant with IEC standards. This enables users to achieve seamless integration during equipment maintenance or retrofitting of existing machinery.Seamless replacementNo need to change the base or drive interface.

- Operational reliabilityFeaturing F-class insulation and IP55 protection rating, enablingYE2 MotorEven in harsh industrial environments such as damp or dusty conditions, it maintains stable operation, significantly reducing the risk of downtime caused by motor failures.

Extensive Application Scenarios and Case Studies

Thanks to its strong adaptability,YE2 MotorWidely used to drive various general-purpose mechanical equipment, such as compressors, fans, water pumps, crushers, and machine tool transmission systems.

Case Study:

A medium-sized textile printing and dyeing factory once faced challenges of aging equipment and persistently high energy consumption. Its production line's circulating water pumps had long relied on outdated Y-series motors, which suffered from severe overheating and frequent malfunctions. During the technical upgrade, the engineering team did not blindly pursue the most expensive top-tier energy-efficient motors. Instead, they conducted a batch replacement based on actual operating conditions.YE2 Series Three-Phase Asynchronous Motors。

The results show that the upgraded pump system not only exhibits significantly reduced operational noise and vibration levels within normal ranges, but also achieved an overall energy savings rate of approximately 4.51% during six months of continuous monitoring. More importantly, due to...YE2 MotorThe procurement cost was moderate, and the factory recouped the cost of replacing the motor in less than a year through savings on electricity bills.

Model Selection Recommendations

When selectingYE2 MotorWhen selecting motors, in addition to focusing on power, speed (pole number), and mounting configuration (e.g., B3 horizontal, B5 vertical), special attention should be given to the manufacturer's production processes. High-quality YE2 motors typically employVacuum Impregnation ProcessHigh-precision bearings ensure the motor's dynamic balance performance during long-term high-speed operation. Additionally, verifying that the product nameplate clearly displays the “China Energy Efficiency Label” is a crucial step in distinguishing authenticity and guaranteeing performance.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206