Professional motor repair and maintenance services, with prompt on-site solutions for all types of malfunctions.

Date: 2025-12-20 Categories: Company News Views: 7120

Excerpt:

In-Depth Analysis of Motor Maintenance: How Professional Care Extends Equipment Lifespan In modern industrial systems, motors are hailed as the “heart” driving production lines. However, due to prolonged high-load operation, harsh environments, or improper handling, motor failures often occur unexpectedly, leading to production halts and substantial economic losses. Therefore, professional motor maintenance is far more than simple component replacement—it involves comprehensive diagnostics, precise calibration, and meticulous upkeep to ensure optimal performance and longevity.

Article Catalog[Hidden]

In-Depth Analysis of Motor Maintenance: How Professional Care Extends Equipment Lifespan

In modern industrial systems, electric motors are hailed as the “heart” driving production lines. However, due to prolonged high-load operation, harsh environments, or improper handling, motor failures often occur at the most unexpected moments, leading to production stoppages and substantial economic losses. Therefore, professionalMotor RepairIt is not merely a simple component replacement, but rather a systematic process involving fault diagnosis, precision repair, and performance optimization. For enterprises, understanding the core maintenance procedures and establishing a scientific maintenance mindset are crucial to ensuring the long-term stable operation of equipment.

Accurate Diagnosis: The First Line of Defense in Repairs

Efficient repairs begin with accurate fault diagnosis. Often, a motor's stoppage is merely a symptom, with underlying causes potentially complex and intertwined. Experienced repair technicians will first conductStatic Testing与Dynamic Analysis。

- Electrical TroubleshootingUsing a megohmmeter and multimeter, test and determine whether there isInterturn short circuit、Phase-to-phase short circuit或Ground faultAmong these,Insulation agingIt is one of the most common causes of electrical failure in motors, typically associated with prolonged operation at excessive temperatures.

- Mechanical Fault DiagnosisUsing a vibration analyzer to inspect bearing condition and rotor balance. Abnormal noise or vibration often indicatesBearing wearOr the shaft is bent.

![[Keywords] [Keywords]](https://simo.org.cn/wp-content/uploads/2025/11/1763987259-dssf.png)

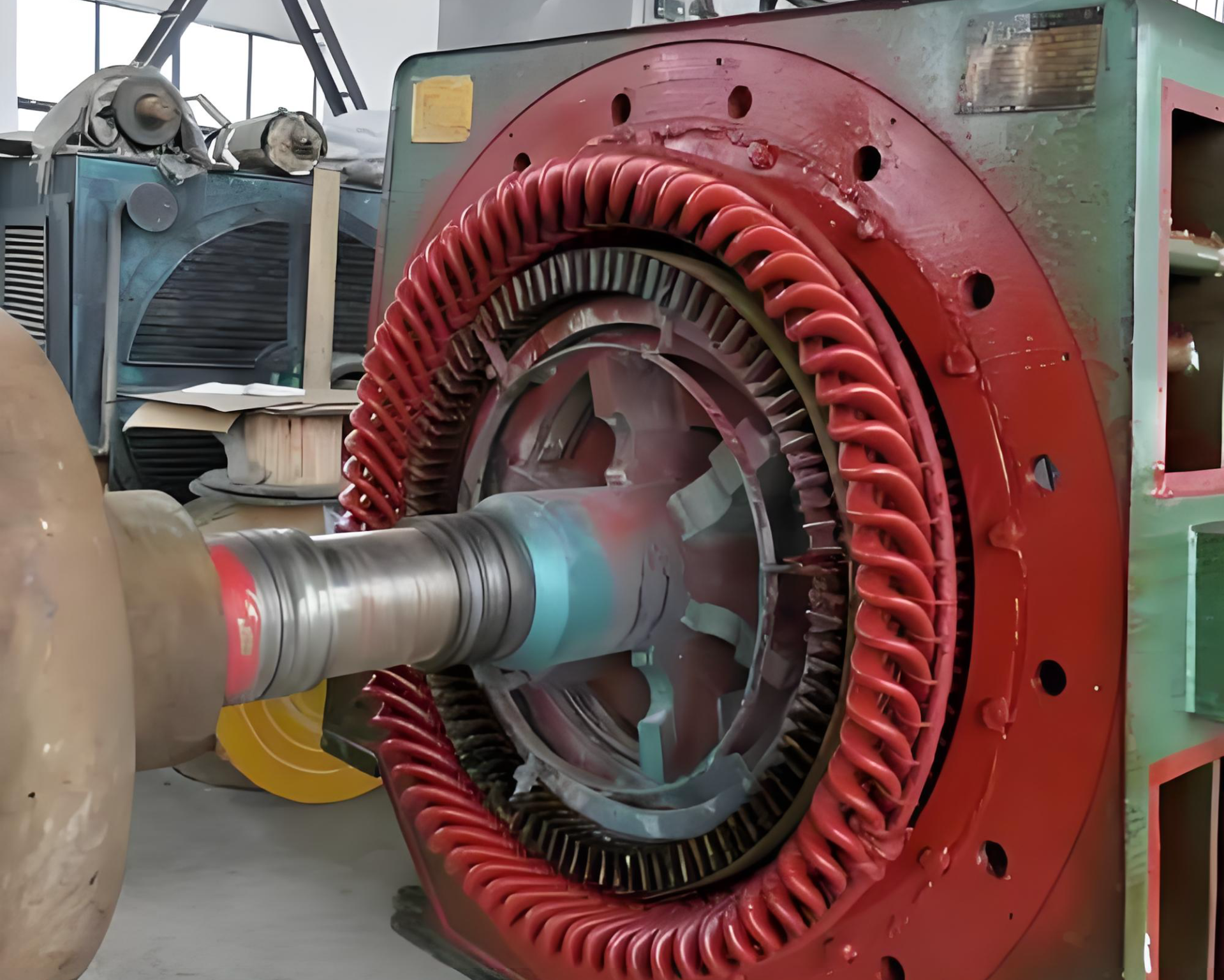

Core Repair Process: Windings and Mechanical Components

Once the source of the fault has been identified, the substantive phase begins.Motor RepairStage. This process demands extremely high precision in the manufacturing technique.

For electrical faults,Stator winding rewindingThis is the most technically demanding stage. Technicians must strictly adhere to original manufacturer specifications when selecting enameled wire, and use high-quality insulating paper and varnish. During the varnish immersion and drying process, temperature and time must be precisely controlled to ensure the insulation layer possesses sufficient mechanical strength and heat resistance.High-quality vacuum pressure impregnation (VPI) processIt can significantly enhance the motor's resistance to moisture and dust, which is particularly crucial for motors operating in humid environments.

As for mechanical components,Bearing ReplacementThis is not a simple disassembly and reassembly process. Professional induction heaters must be used for installation, and forceful hammering is strictly prohibited to prevent damage to the bearing clearance. Furthermore, the tolerance fit inspection of the end cover bearing housing must not be overlooked; excessive looseness or tightness will shorten the service life of the new bearings.

Case Study: The Value of Preventive Maintenance

A large textile factory frequently encountered issues with its main drive motors burning out, requiring major overhauls on average once every quarter, which severely impacted delivery schedules. After introducing professionalMotor RepairAfter the team arrived, they did not rush to replace the motor with a new one, but instead conducted a thorough dissection and analysis of the faulty motor.

Diagnostic findings revealed excessive environmental lint accumulation at the facility, causing blockages in the motor's cooling air ducts. This prolonged exposure to excessive temperature rise accelerated insulation layer brittleness. The maintenance team not only repaired the coils but also recommended installingDust Filterand established a monthly cleaning schedule. Since implementing this program, the factory's motors have operated continuously for 18 months without any major repairs.

This case vividly illustrates that integratingPreventive MaintenanceIntegrating into daily management is far more economical and effective than remedial measures after the fact. By regularly monitoring motor current, temperature, and vibration data, enterprises can shift from reactive maintenance to proactive management, thereby maximizing equipment potential.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206