High-efficiency energy-saving variable-frequency speed-regulated motors enable precise control in industrial automation.

Date: 2025-12-11 Categories: Faq Views: 5024

Excerpt:

Article Title: Variable Frequency Drive Motors: The Key Force Reshaping Industrial Energy Efficiency and Control Precision Foreword Driven by the wave of Industry 4.0, manufacturing enterprises have set unprecedentedly high demands for equipment “energy efficiency” and “control precision.” Faced with rising energy costs and precision machining requirements, traditional fixed-speed motors struggle to meet the flexibility demands of modern production. As the “heart” of industrial automation systems, variable frequency drive motors leverage their

Article Title:Variable Frequency Drive MotorThe Key Force Reshaping Industrial Energy Efficiency and Control Precision

preamble

Driven by the wave of Industry 4.0, manufacturing enterprises have set unprecedentedly high demands on equipment “energy efficiency” and “control precision.” Faced with rising energy costs and precision machining requirements, traditional fixed-speed motors struggle to meet the flexibility demands of modern production. As the “heart” of industrial automation systems,Variable Frequency Drive MotorWith its outstanding energy-saving characteristics and precise speed control capabilities, it is increasingly becoming the preferred solution for upgrading various types of machinery and equipment. Not only does it resolve the issue of poor heat dissipation at low speeds in traditional motors, but it has also become a core tool for enterprises to achieve cost reduction and efficiency enhancement.

What Is a Variable Frequency Drive Motor and Its Core Advantages

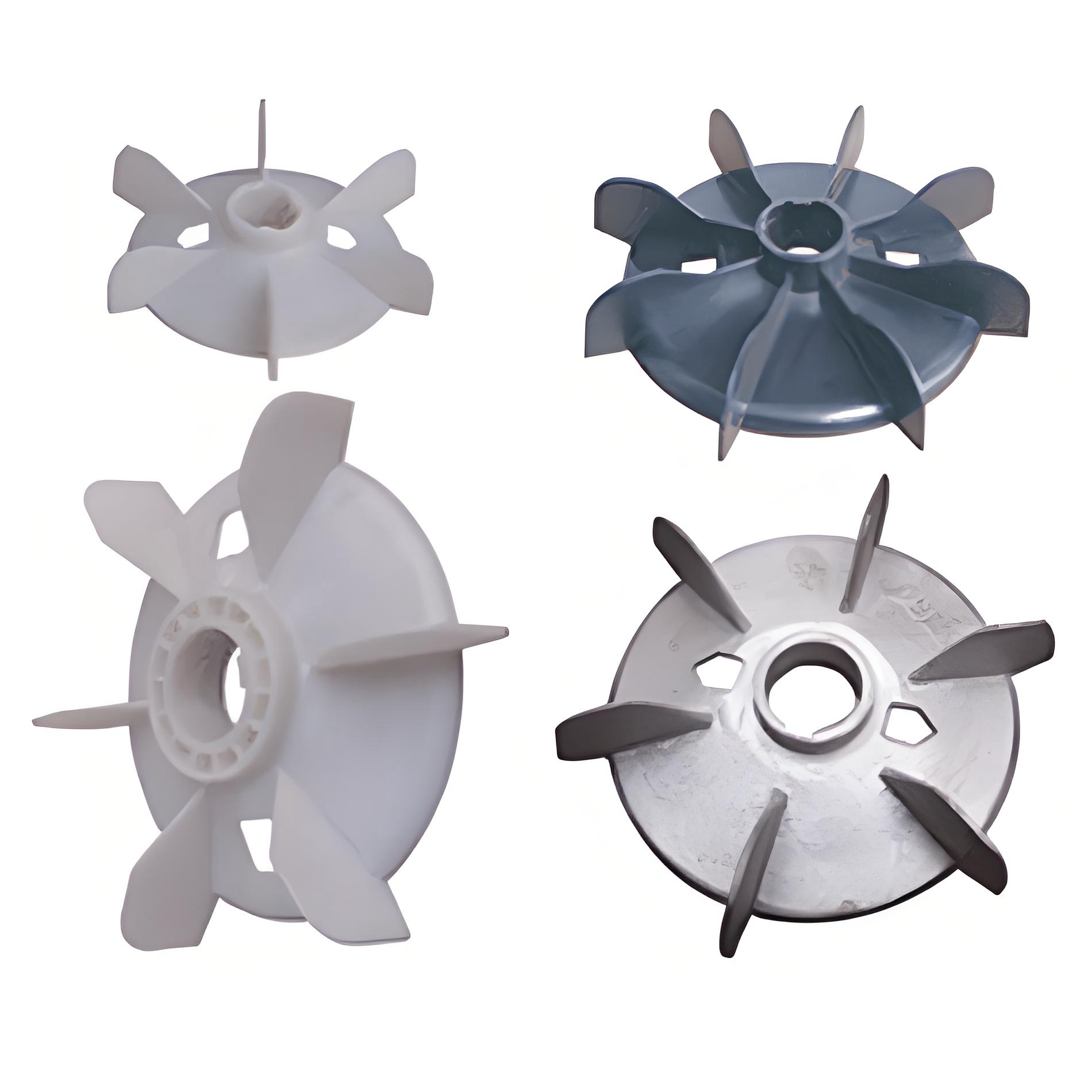

Variable Frequency Drive MotorIt is not simply a “standard motor plus inverter,” but rather a specialized motor specifically designed for the power supply characteristics of variable-frequency power sources. Compared to conventional asynchronous motors, its most significant structural difference lies in the inclusion ofIndependent forced-air cooling systemThis means that regardless of whether the motor is operating at low or high speeds, its cooling fan maintains a constant rotational speed. This effectively prevents the risk of overheating and burnout that occurs in conventional motors during low-frequency operation due to insufficient airflow.

For enterprises pursuing high-efficiency production, the core value of adopting this motor is primarily reflected in the following two aspects:

- Significant energy savingsIn applications involving loads such as fans and pumps, flow rate is controlled by adjusting motor speed, with energy consumption typically proportional to the cube of the rotational speed. ByVariable Frequency Drive MotorWhen used with variable frequency drives, it can prevent the significant energy waste caused by traditional valve throttling.

- Superior control performanceIt features a wider speed adjustment range, enabling stepless speed regulation. During the startup phase, the motor can achieveSoft StartThis significantly reduces the impact of starting currents on the power grid while also minimizing wear on the mechanical transmission system, thereby extending the overall service life of the equipment.

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2023/08/1764154088-26173753.jpg)

Case Study: Energy-Saving Retrofit of Fan Systems in a Chemical Plant

To gain a more intuitive understandingVariable Frequency Drive MotorTo illustrate its practical effectiveness, we can refer to a case study of a large chemical plant's circulating fan retrofit. The plant originally used conventional motors to control airflow by adjusting damper flaps, resulting in a long-term “overkill” scenario where the motors were significantly underutilized. This led to severe energy waste and excessive motor noise.

Upon introductionVariable Frequency Drive MotorAfter system commissioning, the engineer modified the control method to automatically adjust motor speed based on pressure signals fed back by sensors.

- Before renovationThe damper opening has been maintained at approximately 60% for an extended period, yet the motor continues to operate at full speed, resulting in extremely high levels of wasted energy consumption.

- After renovationThe motor speed automatically reduces to approximately 65% of the rated speed based on actual demand.

After six months of operational data monitoring, the system achieved a comprehensive energy savings rate exceeding 35%. Additionally, by eliminating damper howling and mechanical vibration, the workshop's working environment has been significantly improved. This case study fully demonstrates that under variable load conditions, precise speed regulation technology is key to reducing operational costs.

How to Properly Select and Maintain

AlthoughVariable Frequency Drive MotorSuperior performance, but in practical applications, proper selection is crucial. When procuring, enterprises must clearly identify whether the load characteristics fall underConstant torque load(such as conveyor belts, air compressors) orVariable Torque Load(such as fans and water pumps).

Additionally, insulation performance is another critical factor that cannot be overlooked. Since the high-frequency pulse voltage output by the inverter can impact the motor's insulation layer, high-qualityVariable Frequency MotorTypically, F-class or H-class insulation materials are used and undergo special insulation reinforcement treatment to prevent premature aging. Only by ensuring perfect compatibility among the motor, inverter, and load can the automation control system achieve its maximum efficiency.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206