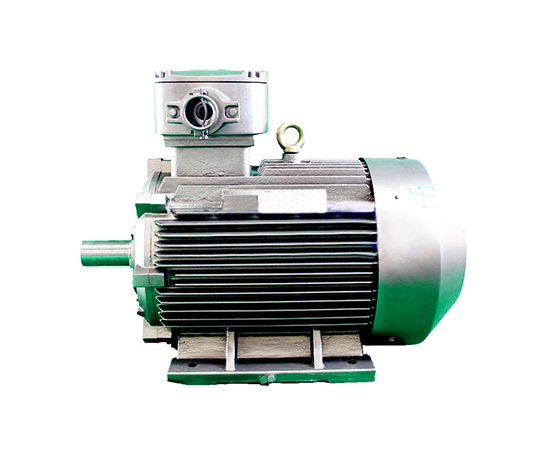

Xi'an Xima High-Voltage Motors: Factory Direct Sales, Full Range of Models, High Efficiency and Energy Saving

Date: 2025-12-09 Categories: Faq Views: 5169

Excerpt:

In the grand narrative of modern heavy industry, the core power of drive systems often determines the efficiency and lifeline of entire production lines. Faced with extreme operating conditions in mining, petrochemicals, power generation, and water conservancy projects, enterprises“ demands for power equipment have long transcended simple ”rotation," instead pursuing higher energy efficiency and lower failure rates.

In the grand narrative of modern heavy industry, the core power of drive systems often determines the efficiency and lifeline of entire production lines. Faced with extreme operating conditions in mining, petrochemicals, power generation, and water conservancy projects, enterprises“ demands for power equipment have long transcended mere ”rotation." Instead, they now advance toward higher energy efficiency, lower failure rates, and extended service life. It is precisely under these stringent selection criteria thatXimaHigh voltage motorsAs a leader in the industrial drive sector, it has become the preferred “heart” for numerous large-scale projects thanks to its solid technical foundation and stable operational performance.

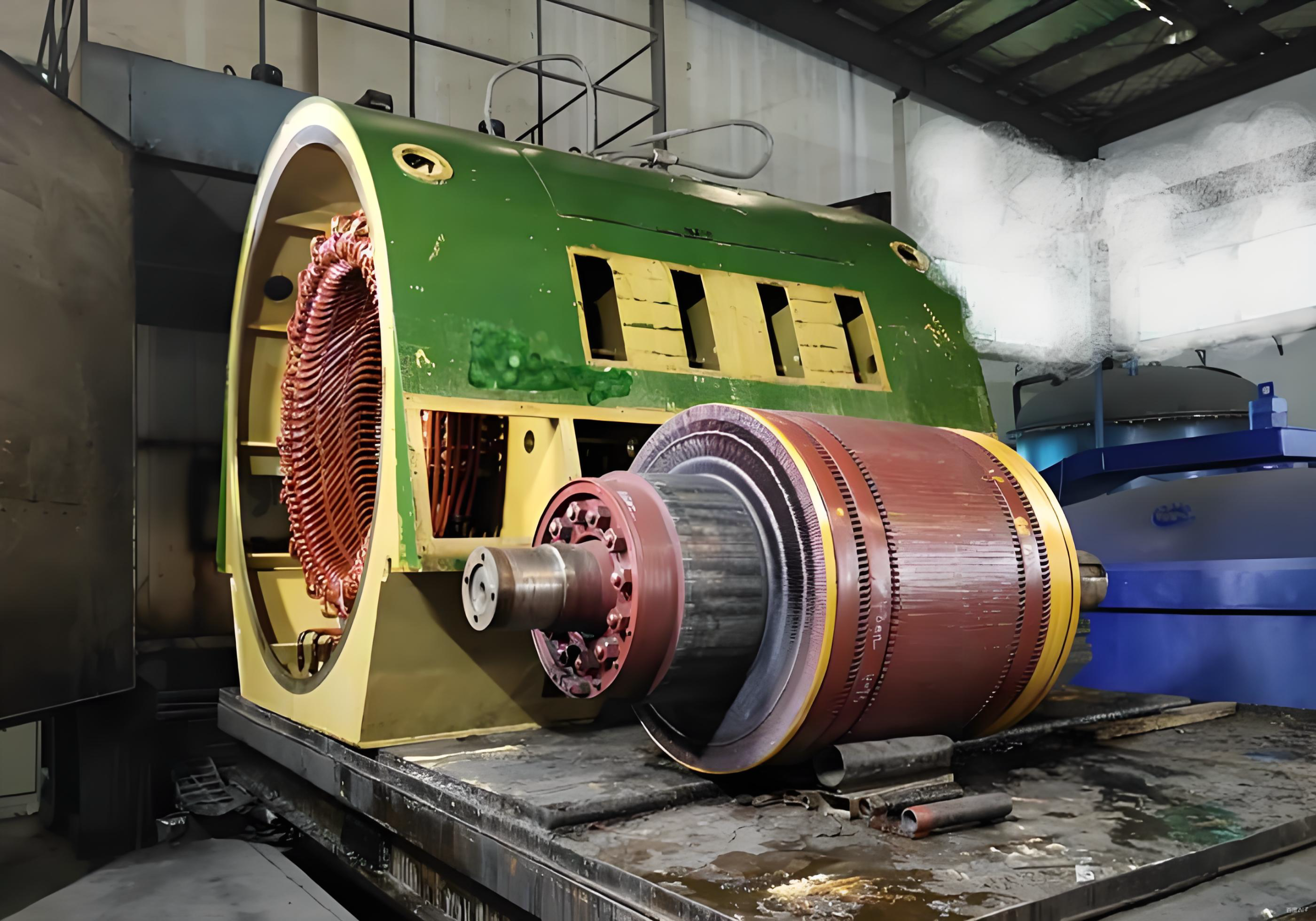

Core Process: Forging an Indestructible Insulation Barrier

High-voltage motors differ from ordinary motors, typically operating at voltage levels of 6kV or 10kV and above, which poses an extremely high challenge to the insulation performance of the windings.Simo High Voltage MotorsThe key to maintaining its leading position in the industry lies in its adoption of advancedVacuum Pressure Impregnation (VPI) Process。

This process ensures that the insulating varnish thoroughly permeates every minute void within the coil, completely eliminating air gaps. This significantly enhances the electrical and mechanical strength of the stator windings. In industrial environments characterized by humidity, dust, or corrosive gases, this specially treated insulation structure demonstrates exceptional resilience. It effectively mitigates the risk of short circuits caused by insulation aging, ensuring the equipment can operate continuously, safely, and reliably over the long term.

The dual balance of energy efficiency and stability

Against the backdrop of the dual carbon goals, energy-saving retrofits for high-energy-consuming equipment are imperative.Simo High Voltage MotorsFluid dynamics and electromagnetic field simulation technologies were incorporated from the initial design phase, enabling in-depth optimization of the airflow path structure and electromagnetic solutions.

- high efficiency and energy savingBy utilizing low-loss cold-rolled silicon steel sheets and an optimized slot design, iron loss and copper loss are significantly reduced. This enables the motor to maintain a high power factor and efficiency during operation, directly helping enterprises lower long-term electricity operating costs.

- Low vibration, low noiseThe unique box-type structural design is not only aesthetically pleasing but also provides exceptional rigidity. Combined with high-precision dynamic balancing calibration, the vibration amplitude of the motor during high-speed operation is kept within an extremely low range. This not only extends the service life of the bearings but also improves the working environment for personnel.

Case Study: Practical Performance of Fan Retrofit at Cement Plant

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2025/11/1764032285-993331.jpg)

To gain a more intuitive understandingSimo High Voltage MotorsTo illustrate its practical application value, we can refer to the induced draft fan retrofit project undertaken by a major cement group. The plant's original outdated high-voltage motors suffered from low efficiency and frequent bearing overheating issues, severely impacting the production schedule of the rotary kiln.

Following the technical team's recommendation, the plant replaced one unit with another of the same power rating.Xima YKK Series High-Voltage MotorsAfter the new motor was put into operation, monitoring data showed that under the same air volume load,The motor current decreased by approximately 81 TP3T.This translates to significant hourly energy savings. More crucially, after three consecutive months of full-load operation, the motor bearing temperature remained consistently within the ideal range, completely resolving the long-standing issue of downtime maintenance that had plagued the factory for years. This case study fully demonstrates the product's exceptional reliability in heavy-load starts and continuous operation.

Flexible Selection and Customized Services

Industrial field requirements vary greatly, and a single specification cannot meet all scenarios.Simo High Voltage MotorsCovering multiple series including Y, YKK, YR, and YRKK, users can find suitable models for driving water pumps, fans, compressors, or high-torque loads like crushers. Particularly for applications requiring special mounting dimensions or protection ratings, its modular design philosophy enables customized production, ensuring each motor integrates precisely into the customer's production system.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206