Xi'an Xima YE4 Series Ultra-High-Efficiency Energy-Saving Three-Phase Asynchronous Motors

Date: 2025-12-08 Categories: Industry News Views: 4470

Excerpt:

A New Benchmark in Green Power: In-Depth Analysis of the Energy Efficiency Advantages and Application Value of the Xima YE4 Motor Against the backdrop of the current “dual carbon” strategy, the industrial sector is undergoing an unprecedented green revolution. As the industrial heart, the energy efficiency level of electric motors directly determines a company's operational costs and carbon emission targets. Faced with increasingly stringent environmental standards and rising energy costs,

A New Benchmark in Green Power: An In-Depth Look at XimaYE4 MotorEnergy Efficiency Advantages and Application Value

Against the backdrop of the current “dual carbon” strategy, the industrial sector is undergoing an unprecedented green revolution. As the heart of industrial machinery, electric motors' energy efficiency levels directly determine a company's operational costs and carbon emission targets. Faced with increasingly stringent environmental standards and rising energy prices, more and more enterprises are seeking efficient solutions to replace traditional high-energy-consumption equipment. In this wave of transformation,Sima YE4 MotorWith its outstanding ultra-high efficiency and stable operational performance, it has become the preferred “green engine” for numerous industrial enterprises seeking to achieve energy conservation and emission reduction.

Technological Breakthrough: Redefining “Ultra-Efficiency”

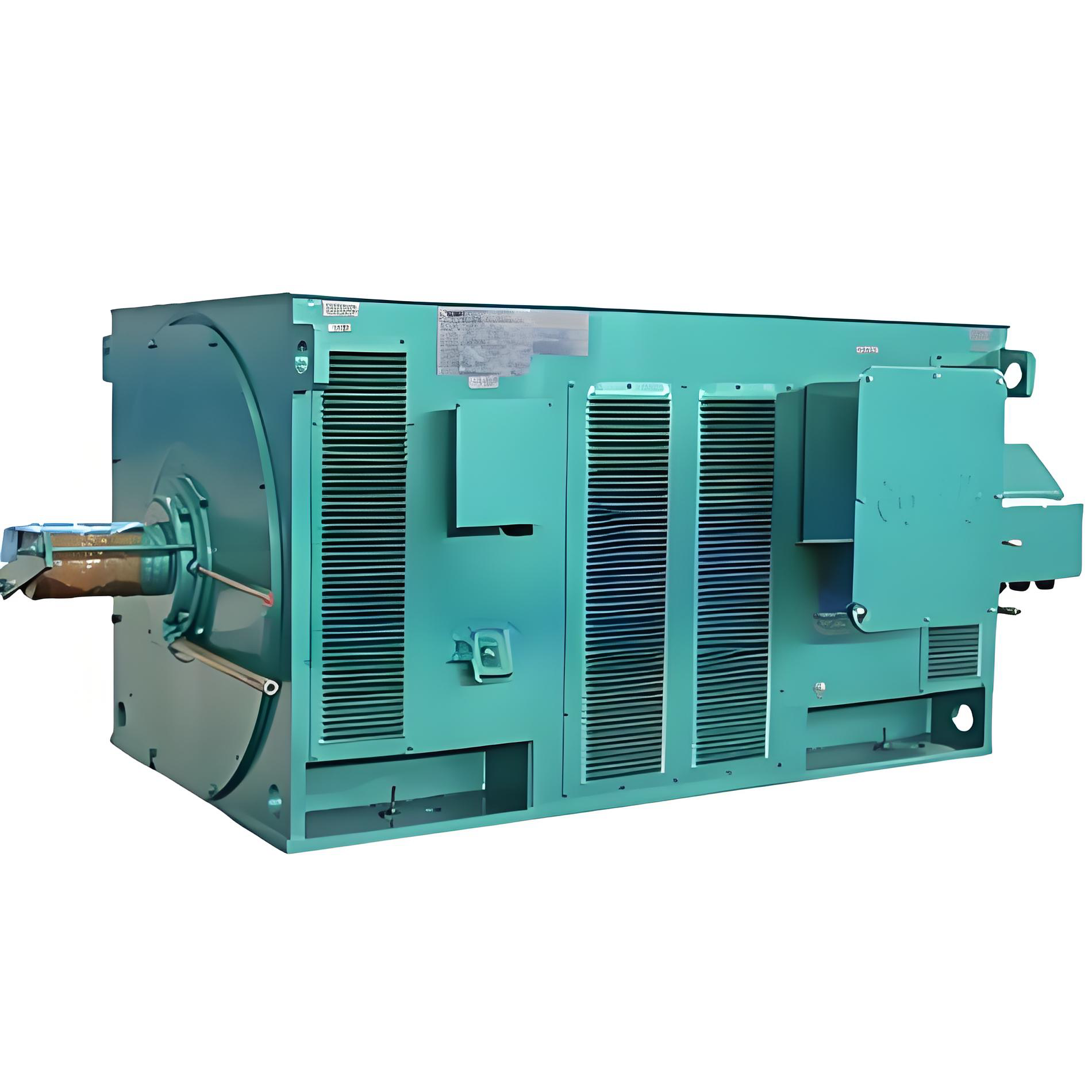

The so-called YE4 series corresponds to the International Electrotechnical Commission (IEC) definition.IE4 Energy Efficiency Standard(Super-efficient), which also meets the Class II energy efficiency standard specified in the current national standard GB 18613-2020.Sima YE4 MotorNot merely a simple product iteration, but rather based onSimo motorsA brand-new design born from years of technical expertise.

![[Keywords] [Keywords]](https://simo.org.cn/wp-content/uploads/2023/08/1764156254-36173716.jpg)

This series of motors employs advanced electromagnetic calculation software in its design, achieving deep optimization of the stator and rotor slot profiles. By adoptingLow-loss cold-rolled silicon steel sheetsDesigned with specially shaped slots, this configuration significantly reduces copper losses, iron losses, and stray losses. This technical treatment results in lower temperature rise during motor operation and extended insulation lifespan. Compared to the standard YE3 series,Sima YE4 MotorThe average efficiency improvement ranges from 1.51 TP3T to approximately 21 TP3T. While this figure may seem modest, the cumulative energy savings generated through continuous 24-hour industrial operation are remarkable.

Economic Ledger: Considering the Full Life Cycle Cost (LCC)

Many procurement managers tend to fall into the trap of focusing solely on price during selection. In reality, within the total lifecycle cost of an electric motor, the purchase price accounts for less than 5%, while over 95% is electricity expenses.

SelectSima YE4 MotorEssentially, it represents a high-return investment. Thanks to its exceptionally high power factor, businesses not only directly save on active electricity costs during operation but also reduce reactive power losses, thereby alleviating pressure on the power grid and minimizing line losses. For equipment like fans, pumps, and compressors that operate under continuous load, the electricity savings typically offset the initial cost of purchasing high-efficiency motors within about a year of commissioning.In the long run, this is a device that can “earn back its worth.”

Practical Case Study: Stability Verification Under High-Load Operating Conditions

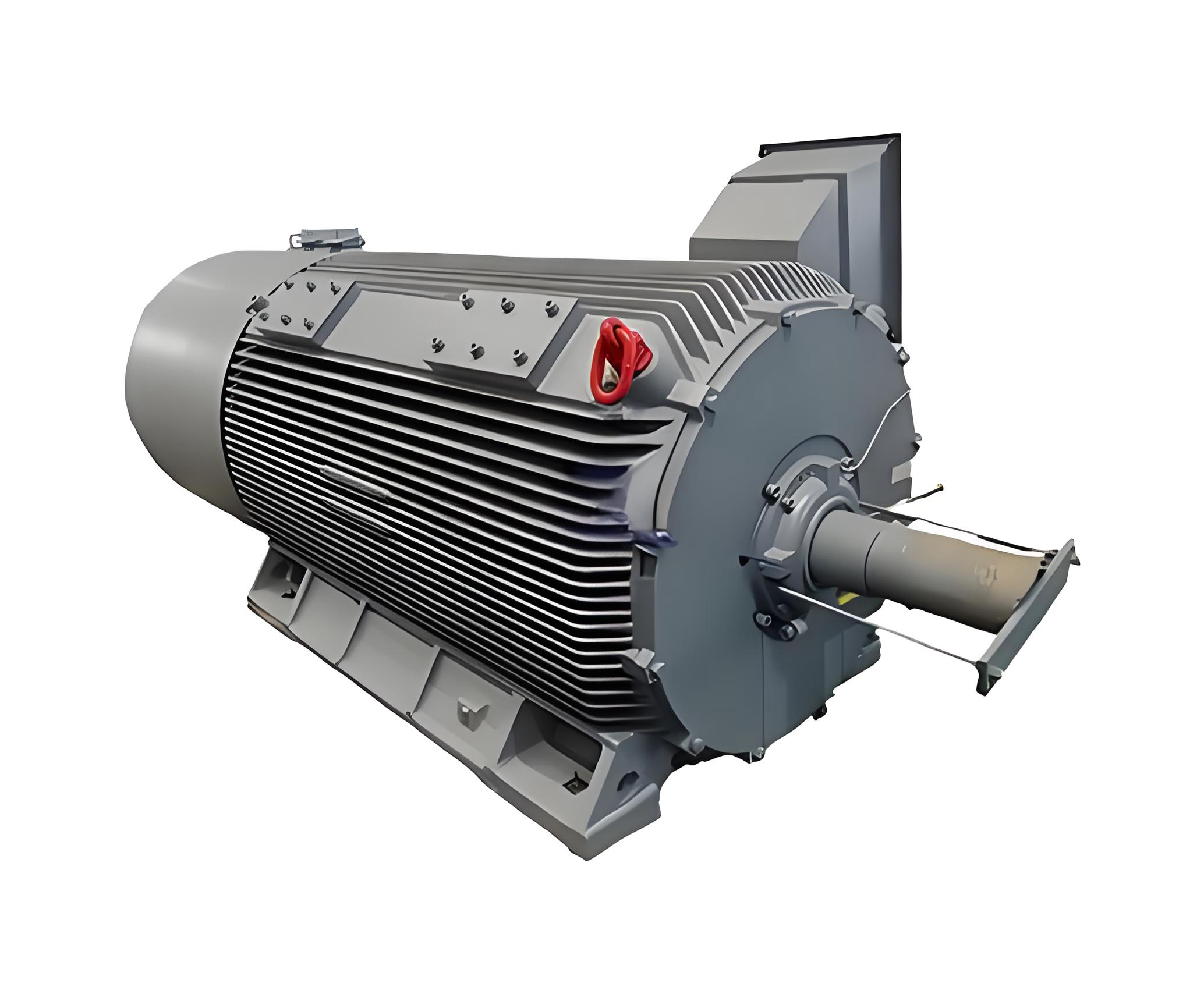

To better illustrate its performance, we can refer to a circulating water system retrofit project at a major chemical enterprise. The company previously operated multiple outdated Y-series units.High voltage motorsEnergy consumption remains high and malfunctions occur frequently. Upon introducingSima YE4 MotorAfter the replacement, analysis of monitoring data collected over a six-month period revealed:

- System efficiency has been significantly improved.At equivalent flow output, the motor input current is significantly reduced, achieving a comprehensive energy savings rate exceeding 121%.

- Enhanced operational stabilityThe optimized airflow design and F-class insulation system (evaluated to B-class standards) of the YE4 motor ensure an exceptionally low failure rate even in harsh summer conditions of high temperature and humidity, significantly reducing the workload for maintenance personnel.

Sima YE4 MotorNot only does it meet the urgent energy-saving demands of traditional high-energy-consumption industries such as petroleum, chemical, power, and metallurgy, but its modular design and flexible installation methods also enable seamless adaptation to various general-purpose machinery, demonstrating exceptional versatility and environmental adaptability.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206