Article Catalog[Hidden]

- Static phase-in cabinet

- Static Power Factor Correction Cabinet: An Advanced Solution for Enhancing Motor Efficiency and Reducing Energy Consumption

- I. Working principle and technical characteristics

- II. Core structure and component design

- III. Performance Features and Technical Advantages

- IV. Technical Parameters and Specifications

- V. Application Areas and Scenarios

- VI. Selection and Installation Guide

- VII. Maintenance and Troubleshooting

- VIII. Benefit Analysis

Static phase-in cabinet

Static Power Factor Correction Cabinet: An Advanced Solution for Enhancing Motor Efficiency and Reducing Energy Consumption

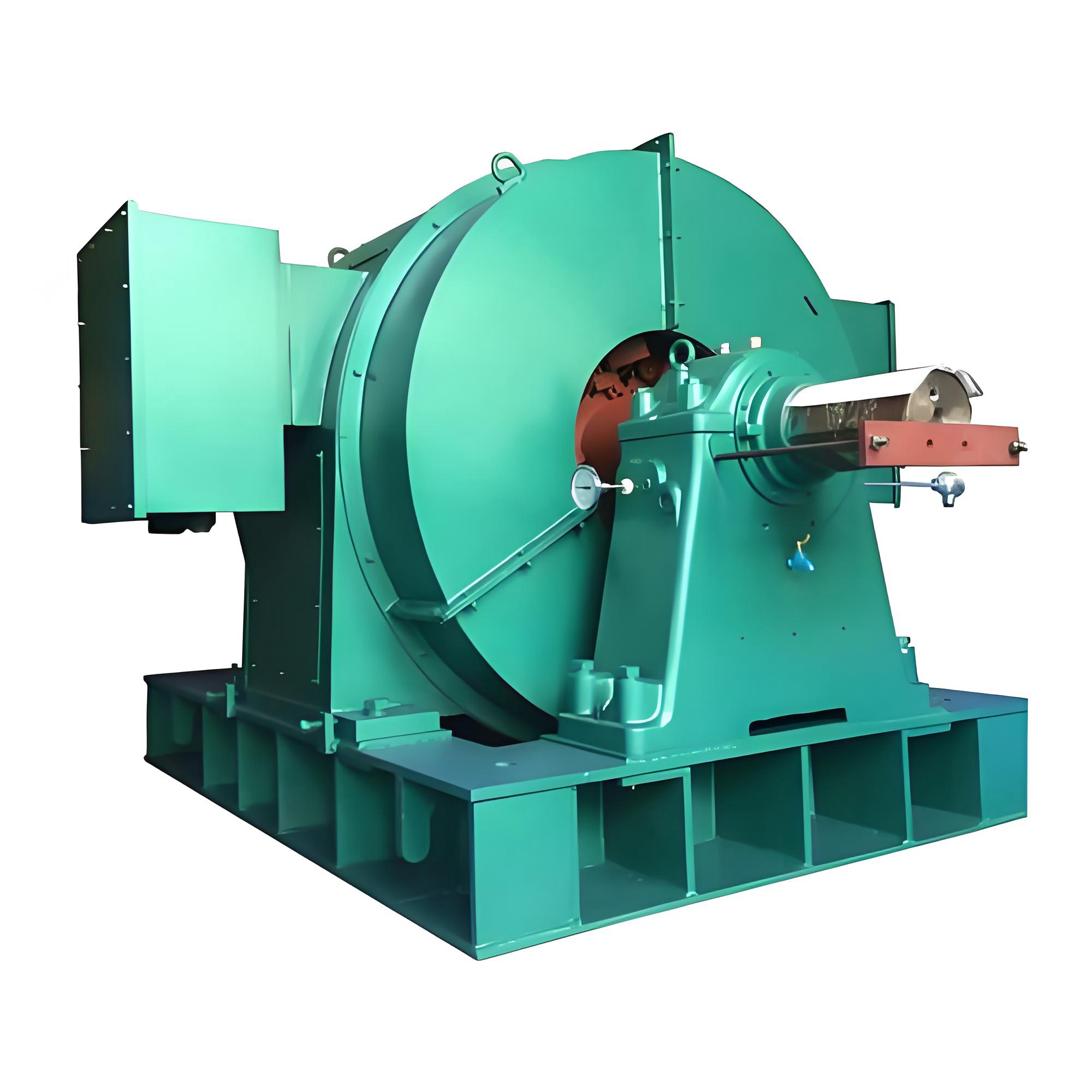

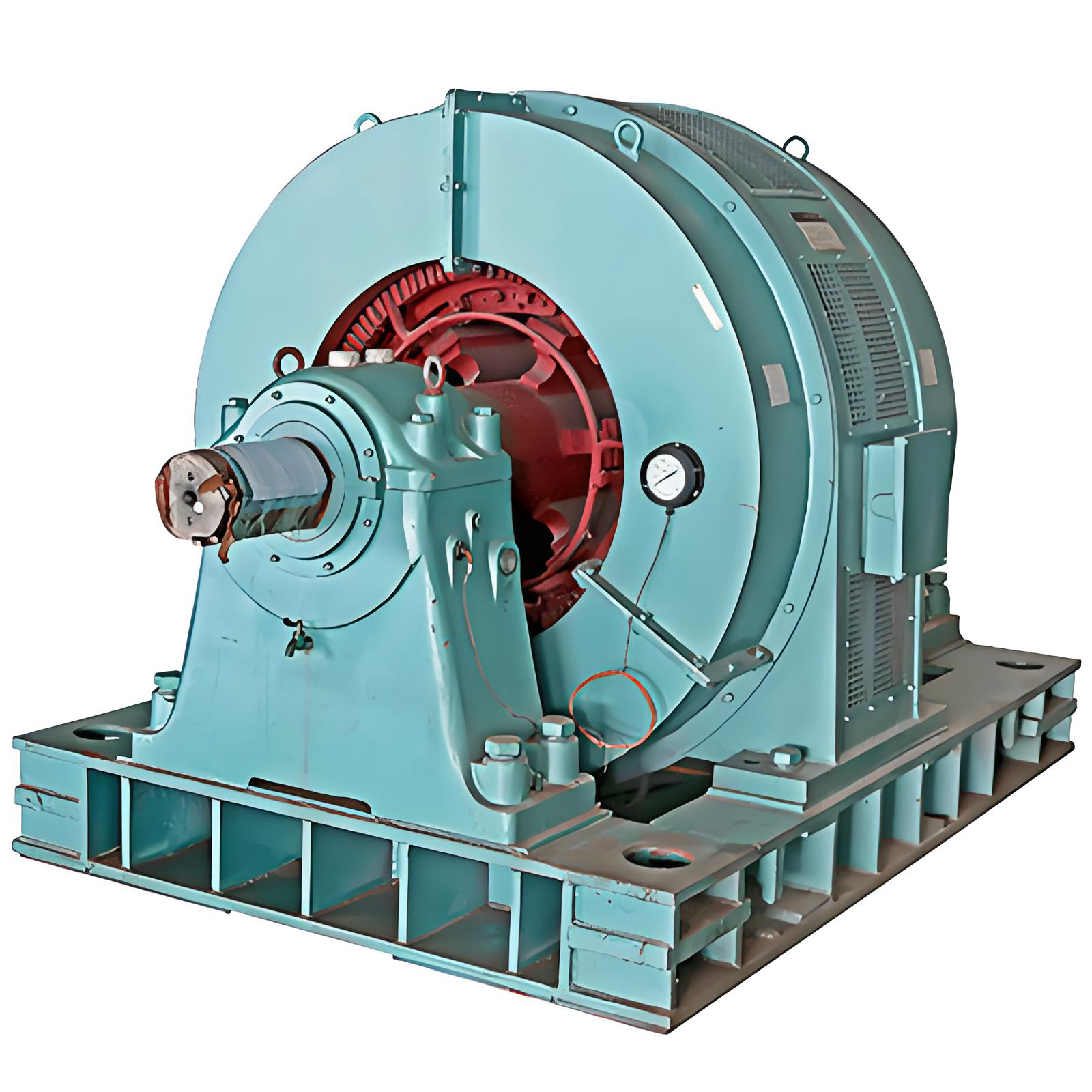

In the field of energy conservation and consumption reduction for medium and large-sized wound-rotor asynchronous motors, static advance phase cabinets are emerging as the ideal choice for industrial enterprises due to their outstanding technical advantages and significant energy-saving effects.

Static phase-in cabinetA novel reactive power compensation device specifically designed for medium and large-sized wound-rotor asynchronous motors.It employsAdvanced AC-to-AC frequency conversion technology and microcomputer control technologyBy connecting in series with the motor rotor circuit, the phase relationship between the rotor current and voltage is altered, therebySignificantly improve the motor power factorreduce stator current, minimize motor and line losses。

As an upgraded replacement for traditional capacitor compensation and rotary phase-advance units, the static phase-advance cabinet offersNo moving parts, no commutator, dust-resistant, long service lifeFeaturing characteristics such as high efficiency and low noise, these motors are being widely adopted for energy-saving upgrades in the cement, chemical, steel, metallurgical, and mining industries.。

I. Working principle and technical characteristics

1. Intelligent working principle

Static power factor correction cabinet adoptsConnected in series with the motor rotor circuitunique designWhen the motor is running, the phase-advance device alters the phase relationship between the rotor current and rotor voltage, therebyOptimize the phase relationship between stator current and voltage in electric motorsto achieve the goal of improving the motor's own power factor and efficiency.。

This compensation method differs fundamentally from the capacitor compensation in parallel with the motor stator side. Capacitor compensation merely compensates for reactive power in the grid outside the motor, reducing the transmission of reactive power in the grid, butThe operating parameters of the motor, such as current and power factor, remain unchanged.Static phase-advance units, however, address the issue directly at the motor itself.Improve the operational status of the motor itselfto enable the motor to operate at high efficiency。

2. Core technical characteristics

- Advanced variable frequency technology:Utilizing AC-to-AC frequency conversion technology and microcomputer controlIt can automatically track changes in motor operating conditions and adjust relevant parameters to achieve optimal compensation performance.

- Design with no moving partsFundamentally overcomes the shortcomings of the commutator structure in self-excited phase-advance cameras, such as susceptibility to dust, short service life, and frequent maintenance.

- Intelligent Control: Utilizing a high-performance microprocessor as its core and employing advanced control technology, it achieves digital and intelligent compensation.

II. Core structure and component design

The static phase-advance cabinet is composed ofMultiple key subsystemscomposed ofHigh-Tech Reactive Power Compensation DeviceEach component has been meticulously designed and optimized to ensure long-term stable operation of the equipment.

1. Key Components

- Control Core: AdoptionHigh-performance microprocessor和Advanced control technologyAchieve digital intelligent control

- Power components:UseHigh-power thyristorForm a cross-cross frequency conversion circuit to achieve phase regulation of the rotor current.

- Detection System: Equipped withHigh-precision sensorReal-time monitoring of motor operating parameters provides accurate data for the control system.

2. Protection and Heat Dissipation System

- Improve the protection mechanism: Has the followingOutput current loss, overheating, and stator current oscillationMultiple protection functions significantly enhance the reliability of the leading-power-factor corrector.

- High-efficiency heat dissipation design: AdoptionOptimized airflow channel design and heat dissipation structureEffectively reduce equipment operating temperature and extend component service life.

- Intelligent Diagnostic System: PossessSelf-Diagnostic FunctionIt can automatically diagnose fault types and take corresponding measures, simplifying maintenance.

III. Performance Features and Technical Advantages

The static power factor correction cabinet boasts multiple outstanding performance characteristics, enabling it to deliver exceptional performance in industrial applications:

1. High-efficiency energy-saving characteristics

- Significantly improve power factor: Can improve the power factor of the motor to0.95 or higherUnder certain operating conditions, it can even reach0.98 or higher

- Significantly reduce reactive power lossesReactive power reduction60% and aboveeffectively conserve electrical energy

- Reduce stator currentReduce the stator current of the motor10%-20%reduce line losses and copper losses20%-30%

2. Advantages of Intelligent Control

- Automatic Tracking Compensation: AdoptionFuzzy Control TechnologyIt can automatically adjust the compensation amount based on the actual operating conditions of the main motor to achieve optimal compensation performance.

- Fully digital controlDigital processing of signals within the control system achieves exceptional accuracy and execution speed.

- No circulation operationThe new generation of non-circulating products overcomes the issues of high self-heating and low reliability encountered by similar circulating products during operation.

3. Safe and Reliable Design

- Complete protection features: Has the followingAutomatic Fault Protection FunctionSimple operation, maintenance without disrupting production

- High Reliability Design: AdoptionModular design and premium componentsEnsure long-term stable operation of the equipment.

- Smart Alarm SystemMonitor equipment status in real time, promptly issue alerts under abnormal conditions, and implement protective measures.

IV. Technical Parameters and Specifications

The main technical parameters of the static power factor correction cabinet are as follows::

| parameter category | Technical specifications and performance indicators |

|---|---|

| Applicable Motors | Medium and Large-Sized Wound-Rotor Asynchronous Motors |

| power range | 90 to 6000 kW (customizable upon request) |

| rotor current | Up to 2500A (depending on model) |

| rated voltage | 380V, 6kV, 10kV, and other specifications |

| Power factor | After compensation, it can reach 0.95 to 0.98. |

| environmental temperature | -10°C to +40°C |

| protection class | IP20, IP30 (can be upgraded as required) |

| altitude | ≤2000m (higher altitudes possible with special design) |

V. Application Areas and Scenarios

Static power factor correction cabinets have a wide range of applications and are particularly suitable for the following scenarios:

1. Heavy industry

- Building Materials and Cement IndustryBall mills, crushers, blowers, and other equipment

- Metallurgical and Steel IndustryRolling mills, compressors, fans, and other high-power equipment

- Mining industry: Elevators, crushers, conveyors and other heavy equipment

2. Complex Manufacturing Industries

- Chemical IndustryVarious types of pumps, compressors, and other equipment

- Paper industryLarge-scale pulping equipment, fans, and pump equipment

- WoodworkingLarge wood processing equipment such as hot mills

3. Special Application Conditions

- Sudden load conditionsEquipment with highly fluctuating loads, such as rolling mills and sugar mill shredders.

- Harsh environments:In dusty and harsh working conditions, it benefits from having no moving parts and being resistant to dust.

- High-energy-consumption equipmentAs major power-consuming equipment in enterprises, large motors have an urgent need for energy efficiency.

VI. Selection and Installation Guide

1. Selection Criteria

Selecting the appropriate static power factor correction cabinet is key to ensuring effective compensation:

- Motor ParametersIncluding motor model, rated power, rated stator voltage/current, rated rotor voltage/current

- Load CharacteristicsLoad type (constant load or variable load) and variation range

- Operating EnvironmentAmbient temperature, humidity, dust conditions, and protection rating requirements

- Installation RequirementsInstallation space, ventilation conditions, distance from the motor, etc.

2. Installation environmental requirements

To ensure the normal operation of the stationary power factor correction cabinet, the installation environment must meet the following requirements:

- environmental conditionsNo hazardous, explosive, or corrosive gases; no severe vibration

- Ventilation RequirementsNo objects shall be placed within 500mm above the phase-advance cabinet. If the trench is enclosed, the cabinet must be elevated 100mm off the ground.

- Electrical ConditionsPower supply voltage: Three-phase AC 380V ±10%, 3TP3T, compliant with national electrical installation standards.

VII. Maintenance and Troubleshooting

Maintenance of static power factor correction cabinets is relatively straightforward, focusing primarily on the following aspects:

1. Periodic inspection and maintenance

- Cooling System InspectionRegularly inspect whether the cooling fan of the phase-shifting device has stopped rotating. If it has stopped, promptly de-phase the device and repair or replace the fan.

- Contactor MaintenanceRegularly inspect the contacts of the two large contactors inside the phase-advance unit to extend the service life of the contactors.

- Dust RemovalRegularly blow out and clean dust from the phase-advance unit to prevent excessive accumulation from affecting the normal heat dissipation of the transformer inside.

2. Common Troubleshooting

- Current fluctuates significantlyUpon entering phase, if the stator current of the motor exhibits significant fluctuations, phase reversal should be performed immediately. Identify the cause and perform maintenance.

- Precautions for Equipment Startup and ShutdownAfter major equipment overhaul or when the phase-advance unit is reactivated after prolonged deactivation, observe whether all indicator lights on the control unit inside the cabinet are functioning normally before initiating the first phase advance.

- Professional RepairFor complex malfunctions, it is recommended to contact a professional technician for diagnosis and repair.

VIII. Benefit Analysis

Investing in static power factor correction cabinets can bring multiple benefits to enterprises:

1. Economic Benefits

- Energy-saving benefitsPower factor improved to above 0.95, reactive power reduced by over 60%, effectively conserving electrical energy.

- Cost recoveryEnergy conservation and consumption reduction have yielded remarkable results.The cost can be recovered in about six months.

- Electricity bill savingsAvoid power factor penalties from utility providers and enjoy electricity bill rebates.

2. Comprehensive Benefits

- Extended equipment lifespanSignificantly reduced motor temperature rise, greatly enhanced overload capacity and efficiency, and extended motor service life.

- System Stability EnhancementReduce motor stator current, lessen grid load, and improve power supply quality.

- Reduced maintenance costsNo moving parts, dust-resistant, high reliability, long service life, easy maintenance

Static power factor correction cabinets, with theirAdvanced Technical Principles、Significant energy savings和Reliable operational performancehas become the standard for reactive power compensation in medium-to-large-sized wound-rotor asynchronous motors.Ideal Choice. itsUnique rotor circuit series connection configuration和Intelligent Control StrategyFundamentally improved the motor's operating state, achieving genuine energy savings within the motor itself.

As the industrial sector continues to demand greater energy efficiency and reduced consumption, static power factor correction cabinets will play an increasingly vital role inMore industries and scenariosDemonstrate its value in practice, creating benefits for industrial enterprises.Greater economic and social benefitsFor enterprises pursuing efficient operations and sustainable development, selecting a static power factor correction cabinet is undoubtedly a wise decision.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206