Article Catalog[Hidden]

- Low-Voltage Solid-State Soft Starter Cabinet: A Complete Intelligent Motor Starting and Control Solution

- I. Product Overview: Revolutionary Breakthrough in Motor Starting Technology

- II. Core Technology Principles and Structural Design

- III. Core Functions and Technical Advantages

- IV. Main Technical Parameters

- V. Application Scenarios and Industry Solutions

- VI. Selection and Installation Guide

- VII. Core Advantages of Xima Low-Voltage Solid-State Soft-Start Cabinets

Low-voltage solid-state softstarter cabinetComplete Solution for Intelligent Motor Starting and Control

I. Product Overview: Revolutionary Breakthrough in Motor Starting Technology

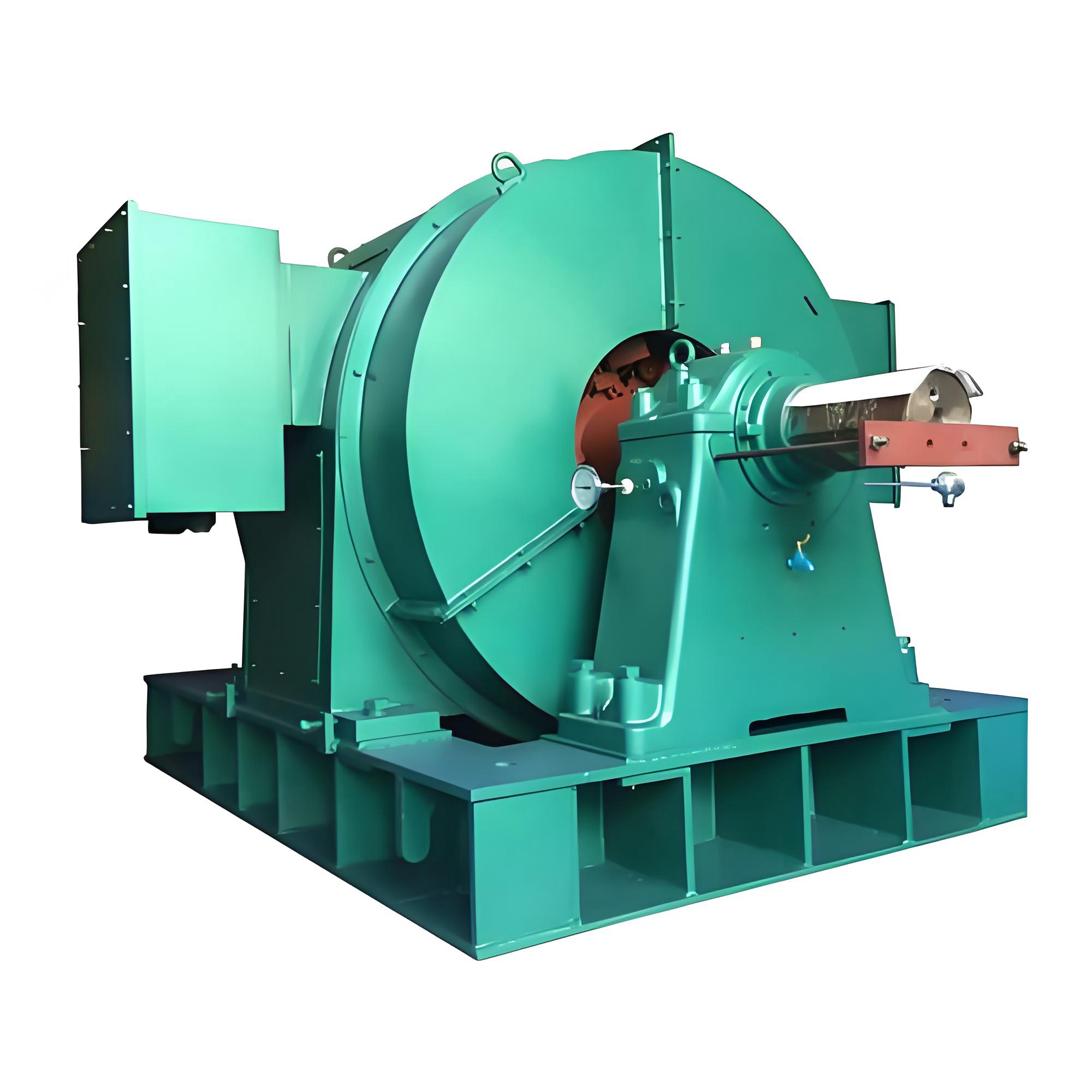

Low voltage solid state soft start cabinetis a type ofAdvanced Power Electronics Technology和Intelligent Microprocessor Control SystemMotor starting equipment, specifically designed forthree-phase asynchronous motorDesignIt achieves this throughThyristor (Silicon Controlled Rectifier) Phase-Shift ControlThe principle enables precise regulation of motor voltage and current, completely resolving issues caused by traditional direct-on-line starting, Y-Δ starting, and autotransformer voltage-reduction starting methods.Significant grid impact, high mechanical stress, and severe energy wasteetc.。

This product has been widely adopted in power generation, metallurgy, mining, chemical processing, construction, water treatment, and other fields, becoming a key component in motor control for modern industrial automation projects.Simo motorsLow-voltage solid-state soft starter cabinet integratesDigital Integration Technology与Intelligent Diagnostic ProtectionFunctionality, not only equipped withSoft start, soft stop, real-time monitoringCore capabilities, and also integratesMultiple Motor ProtectionThe mechanism provides users with a complete and reliable motor control and protection solution.。

II. Core Technology Principles and Structural Design

1. Principles of Intelligent Control

Low-voltage solid-state soft starter cabinetHigh-performance microprocessor (CPU) As the core control unit, throughOptical Fiber Isolation Triggering TechnologyPrecise control of the conduction angle of series-parallel thyristor assembliesDuring the motor start-up process, the system automatically and gradually increases the terminal voltage and torque of the motor to achieveConstant current start, voltage ramp startMultiple flexible start modesWhen the motor approaches its rated speed, the bypass contactor automatically engages to ensure the motor operates efficiently at full voltage.。

Its technical principle is based onThyristor Phase-Shift ControlBy controlling the variation of the trigger angle through a microprocessor, the conduction level of the thyristor is adjusted, thereby altering the magnitude of the motor's input voltage to achieve the purpose of soft starting the motor.This precise control ensures a smooth motor start-up process, minimizing impact on the power supply system and mechanical equipment.。

2. Precision Structural Design and Safety Features

- Modular Component DesignIncludes thyristor modules, motor protection modules, communication modules, and control transformers, supporting rapid maintenance and customizable expansion.

- Three-room isolation structureThe design employs mutually independent power component compartments, main control relay compartments, and main circuit connection compartments, effectively isolating high-voltage, low-voltage, and control circuits to enhance the system's interference resistance.

- Multi-layered protection mechanism: IntegrationRC Absorption Unit和Static and Dynamic Equalization TechnologyProvides surge voltage absorption and overload protection (125% continuous rating, 500%/60s overload capacity)

- Optimized thermal designFor units rated at 75 kW and below, natural air cooling is employed; for units rated at 90 kW and above, forced air cooling is utilized. This ensures stable operation of the equipment under all operating conditions.

III. Core Functions and Technical Advantages

1. Diverse Start-Up and Shutdown Modes

- Current-Limiting Soft StartLimit the inrush current to the rated value.100%-500%Avoid sudden voltage drops in the power grid, reduce distribution capacity, and prevent additional investment in capacity expansion.

- Voltage Ramp ControlInitial torque adjustable (30%-90%Rated voltage), smoothly increases motor speed, suitable for various types of loads.

- Pulse conflict jump startSuitable for scenarios with high mechanical static friction in motor-driven loads, providing an initial surge torque to overcome static friction.

- Soft Stop FunctionBy gradually reducing the voltage to eliminate the load on pump-type equipment."Water hammer effect"Protect the pipeline system; soft shutdown time can be0–60 secondsInternal adjustment

2. Intelligent Diagnostics and Communication Capabilities

- Human-Computer Interface: Equipped withLCD display and control panelUsers can conveniently engage in human-machine dialogue, configure various parameters, and monitor changes in data throughout the startup process.

- Remote Monitoring Integration:Built-inRS-485Communication interface supporting protocols such as Modbus, enabling remote monitoring through microcomputer network control.

- Fault Traceability FunctionStores recent fault information (non-volatile memory), assists in rapid diagnostics, and features comprehensive protection functions including overvoltage, undervoltage, input phase loss, output phase loss, current imbalance, start-up overcurrent, and operational overcurrent.

- Analog OutputProvides a standard 4–20 mA analog current output for easy integration into DCS systems for process control.

3. Energy Efficiency and Economic Advantages

Compared to traditional starting solutions, low-voltage solid-state soft starter cabinets canSignificantly reduce starting currentreduce the impact on the power grid, minimize equipment vibration and noise, and help extend the service life of the motor.This helpsReduce distribution capacityAvoid capacity expansion investmentsAt the same time, by reducing the starting stress, it can significantlyExtend the service life of electric motors and related equipment, saving businesses significant maintenance and replacement costs。

IV. Main Technical Parameters

V. Application Scenarios and Industry Solutions

1. Typical Load Adaptation

- PumpsHigh-lift pumps, water transfer pumps, circulation pumps, etc., eliminate water hammer hazards. The soft-stop function effectively prevents water hammer phenomena in piping systems.

- Fans and CompressorsProtect high-inertia loads by utilizing a heavy-load start mode (extended acceleration time) to reduce start-up impact.

- Heavy machineryBall mills, crushers, conveyors, mixers, etc., reduce mechanical impact and extend equipment service life.

- Conveying equipmentBelt conveyors, chain plate conveyors, etc., achieve smooth starts to prevent material spillage.

2. Industry Application Cases

- Power industryProtect auxiliary motors in power plants and distribution systems to ensure the stability and continuity of power generation.

- Cement IndustryFor ball mills, fans, crushers, and other equipment, addressing equipment lifespan issues under frequent start-stop conditions.

- Chemical IndustryProvide reliable start-up protection for pumps, compressors, fans, and similar equipment to prevent safety incidents caused by motor failures.

- Metallurgical industryIn steel smelting and processing operations, protect various critical motor equipment such as rolling mill motors and fan motors.

- Mining industryUsed in mining hoists, drainage pumps, ventilation fans, and other equipment to ensure safe production in mines.

VI. Selection and Installation Guide

1. Key Selection Factors

- Motor ParametersRated voltage, power, starting torque requirements, and load characteristics (pumps, fans, or heavy machinery)

- Operating EnvironmentAltitude, ambient temperature, protection rating, and explosion-proof requirements (capacity should be reduced accordingly when operating above 2000 meters altitude)

- Functional RequirementsCommunication protocols, soft-stop requirements, remote control methods

- Load TypeStandard or heavy-duty load, starting frequency (standard products recommend no more than 15 starts/stops per hour)

2. Key Points for Installation and Maintenance

- Supporting equipmentWhen in use, it must be connected with a bypass contactor and necessary motor protection devices.

- installation environment: Should be installed in locations free of flammable, explosive, or corrosive gases, without conductive dust, and with vibration levels below 0.5G.

- Cooling conditionsEnsure adequate ventilation around the cabinet. For forced-air cooling models, ensure the cooling fan is functioning properly.

- Maintenance CycleRegularly inspect RC absorption units, thyristor configurations, and trigger circuits; clean heat dissipation ducts.

VII. Core Advantages of Xima Low-Voltage Solid-State Soft-Start Cabinets

- Technical CertificationCertified under the ISO 9001 Quality Management System to ensure consistent and reliable product quality.

- Reliability DesignAll electrical components undergo rigorous screening. The main control board is subjected to high-temperature cycling tests and vibration tests to ensure high reliability of products upon shipment.

- Smart ProtectionThe motor start-up process features comprehensive protection functions including phase loss, overload, overcurrent, overheating, and start-up time limitation.

- Flexible ConfigurationWhen the soft starter's rated power exceeds the actual load power, the actual output current of the soft starter can be adjusted within a certain range to match the actual load current.

- Full-cycle serviceOne-stop support from solution design and parameter debugging to technical training, with lifetime upgrade services provided.

Low-voltage solid-state soft starter cabinets serve as the ideal replacement for traditional starting equipment. Through their advanced control technology and comprehensive functional features, they provide users with smarter, more reliable motor starting solutions.As industrial automation continues to advance, this product will demonstrate its value across broader applications, delivering greater benefits to industrial users.。

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206