Simo motors successfully repaired the core high-voltage motor of a large mining company

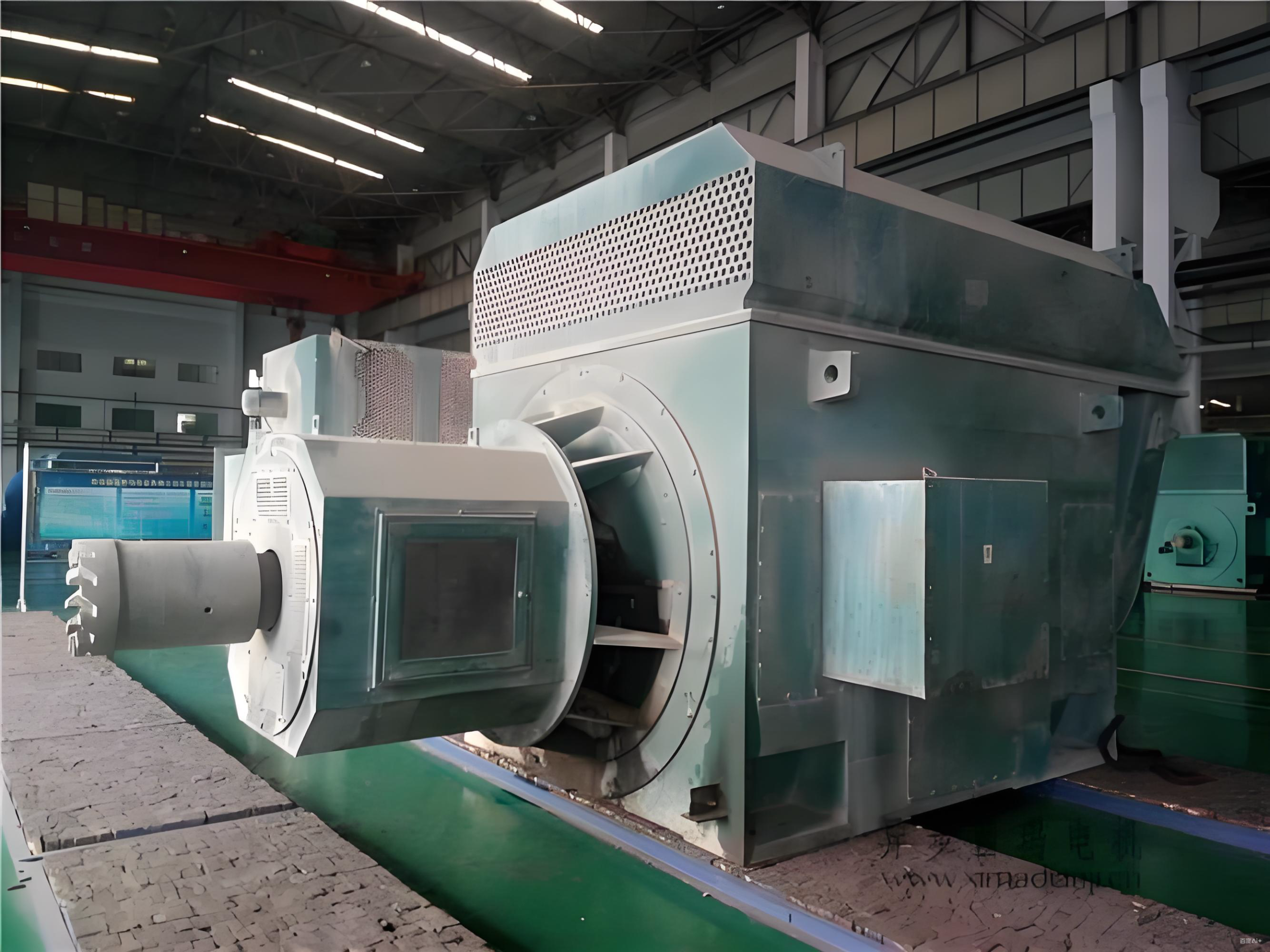

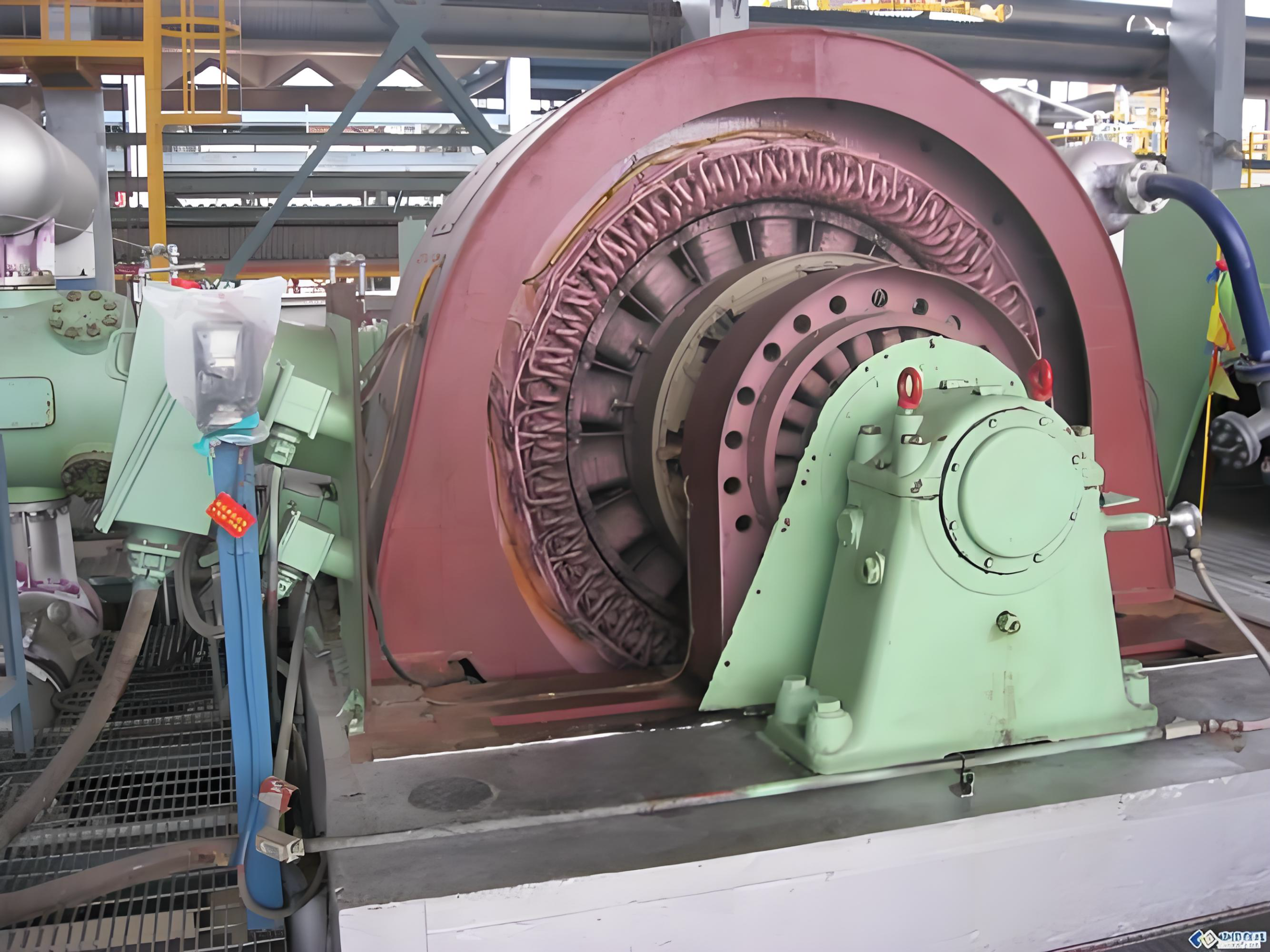

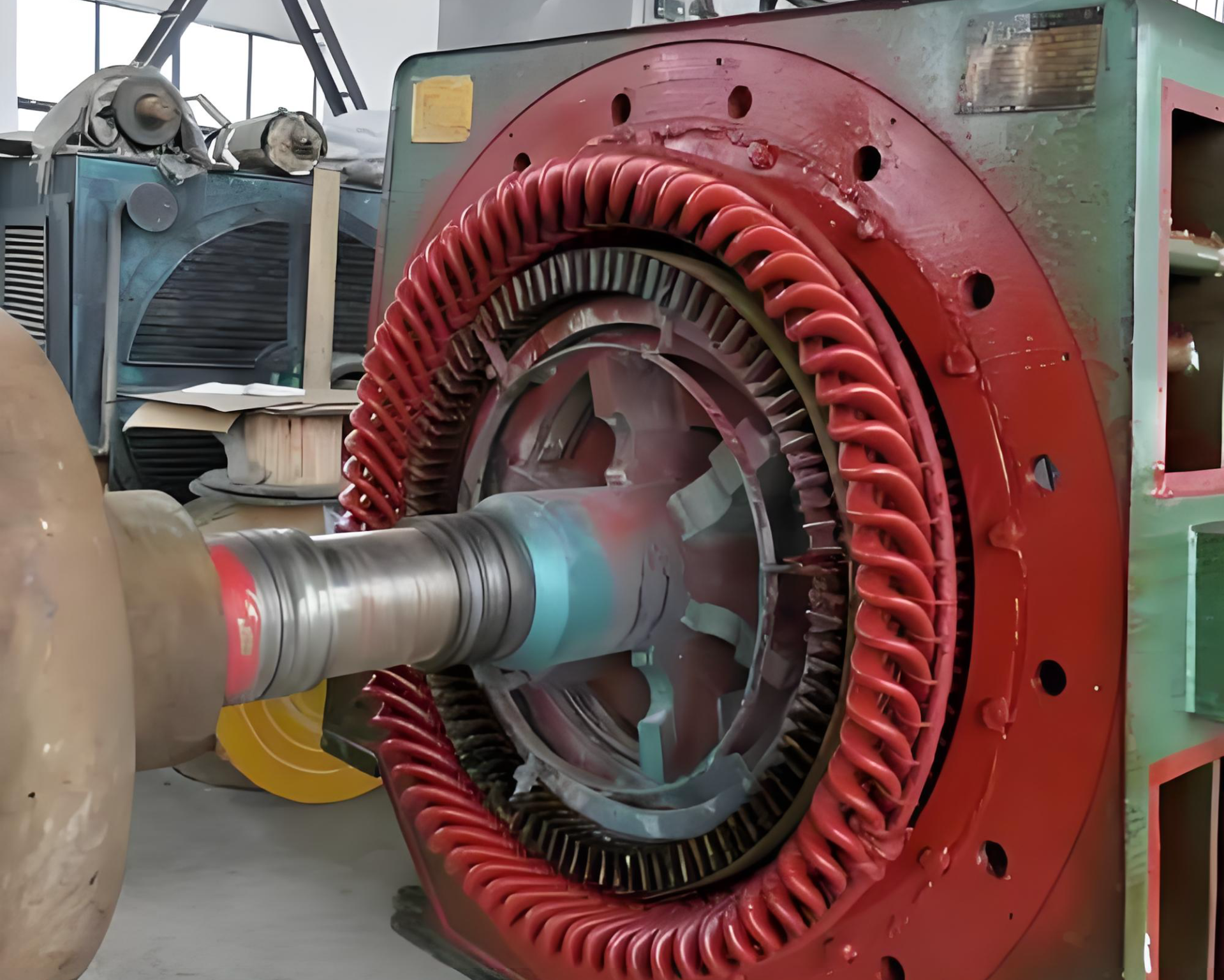

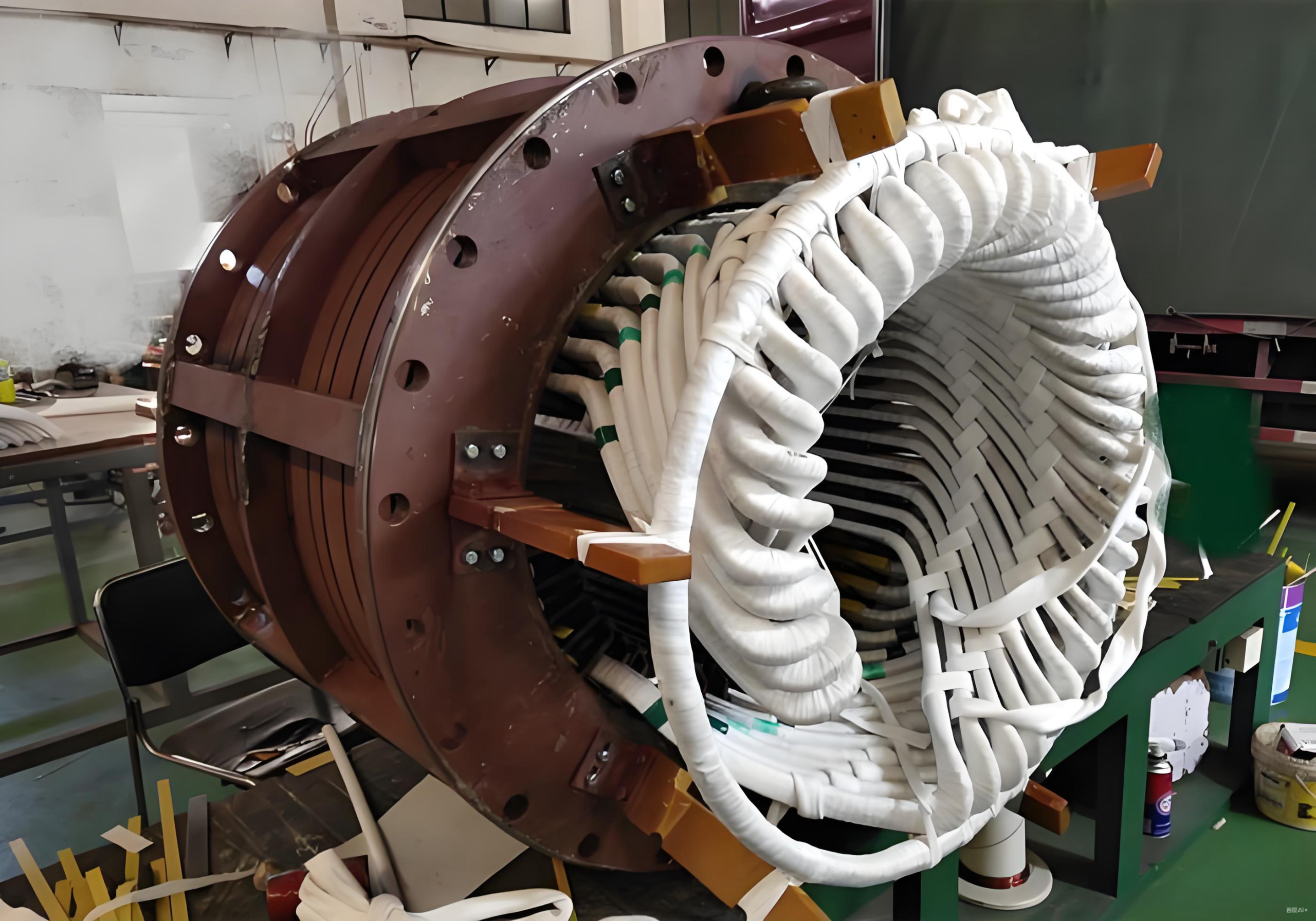

This article analyzes the whole process of repairing a critical 10kV, 1800kW high-voltage motor for a large mining company. In the face of the motor's stubborn faults of excessive vibration and repeated bearing burnout, the Simo team not only eradicated the problem through precise diagnosis and systematic maintenance programs, but also established a predictive maintenance system for the client, avoiding major production stoppage losses. This case demonstrates Simo's comprehensive technical strength and service value in the field of large motor maintenance.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206