Advancing Green Industrial Development: A Comprehensive Analysis of the Advantages and Applications of High-Efficiency Energy-Saving Motors

Date: 2025-12-07 Categories: Company News Views: 5946

Excerpt:

Say Goodbye to Hidden Waste: How High-Efficiency Motors Reshape Corporate Competitiveness Amid the dual challenges of China's “dual carbon” goals and fluctuating energy costs, industrial manufacturers face unprecedented pressures. Many executives reviewing financial statements discover that electricity expenses account for a staggering proportion of production costs. Statistics show that motor systems consume approximately [X]% of a factory's total power usage.

Article Catalog[Hidden]

Say Goodbye to Hidden Waste:Energy efficient motorsHow to Reshape a Company's Core Competitive Advantage

Against the dual backdrop of today's “dual carbon” goals and persistently volatile energy costs, industrial manufacturing enterprises face unprecedented challenges. Many business managers reviewing financial statements discover that electricity expenses account for a staggering proportion of production costs.Statistics indicate that motor systems consume approximately 75% of total industrial electricity usage, with a significant portion of this consumption stemming from outdated, inefficient power equipment. This represents not only a waste of energy but also a drain on corporate profits. Therefore, upgrading traditional motors toEnergy efficient motorsIt is no longer an optional choice, but rather an essential path for enterprises to reduce costs, enhance efficiency, and boost their green competitiveness.

What is a truly high-efficiency energy-saving motor?

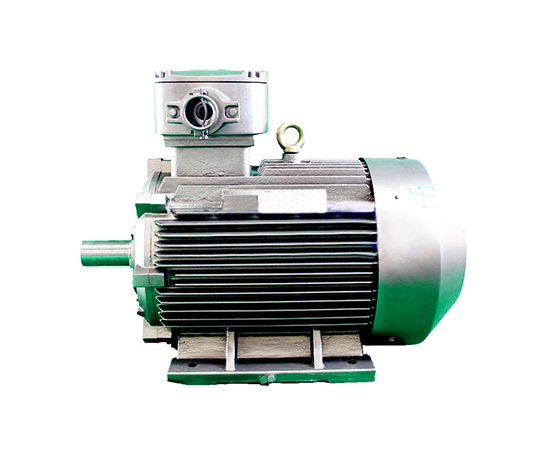

Many people mistakenly believe that any new motor is energy-efficient, but that's not necessarily true.Energy efficient motorsThese motors employ innovative designs, manufacturing processes, and materials to reduce losses in electromagnetic energy, thermal energy, and mechanical energy, thereby enhancing output efficiency. Compared to standard motors, they typically meet or exceed national energy efficiency standards of Class II (IE3) or even Class I (IE4).

From a technical perspective,High-efficiency motorBy optimizing the design of the stator and rotor and utilizing higher-quality magnetic materials (such as cold-rolled silicon steel sheets), the motor generates less heat during operation and runs more smoothly. This means it can save between 31% and 151% more energy compared to conventional motors while delivering the same power output. While the savings per unit may seem modest, for production lines operating 24/7 year-round, this represents a significant “hidden fortune.”.

Doing the math: Total Cost of Ownership

When making purchases, companies are oftenEnergy efficient motorsThe relatively high initial purchase price may deter some buyers. However, this is a common misconception. In the motor's total lifecycle cost (LCC), the purchase cost accounts for only approximately 21% to 51%, while maintenance costs represent a minor proportion.The cost exceeding 90% is actually the electricity expense during runtime.。

adoptionEnergy efficient motorsAt its core, this represents a high-return investment strategy. Typically, businesses recoup the additional procurement costs within one to one and a half years through savings on electricity bills. For the subsequent decade or longer, every kilowatt-hour saved translates directly into net profit.

Case Study: Fan Retrofit at a Ceramic Factory

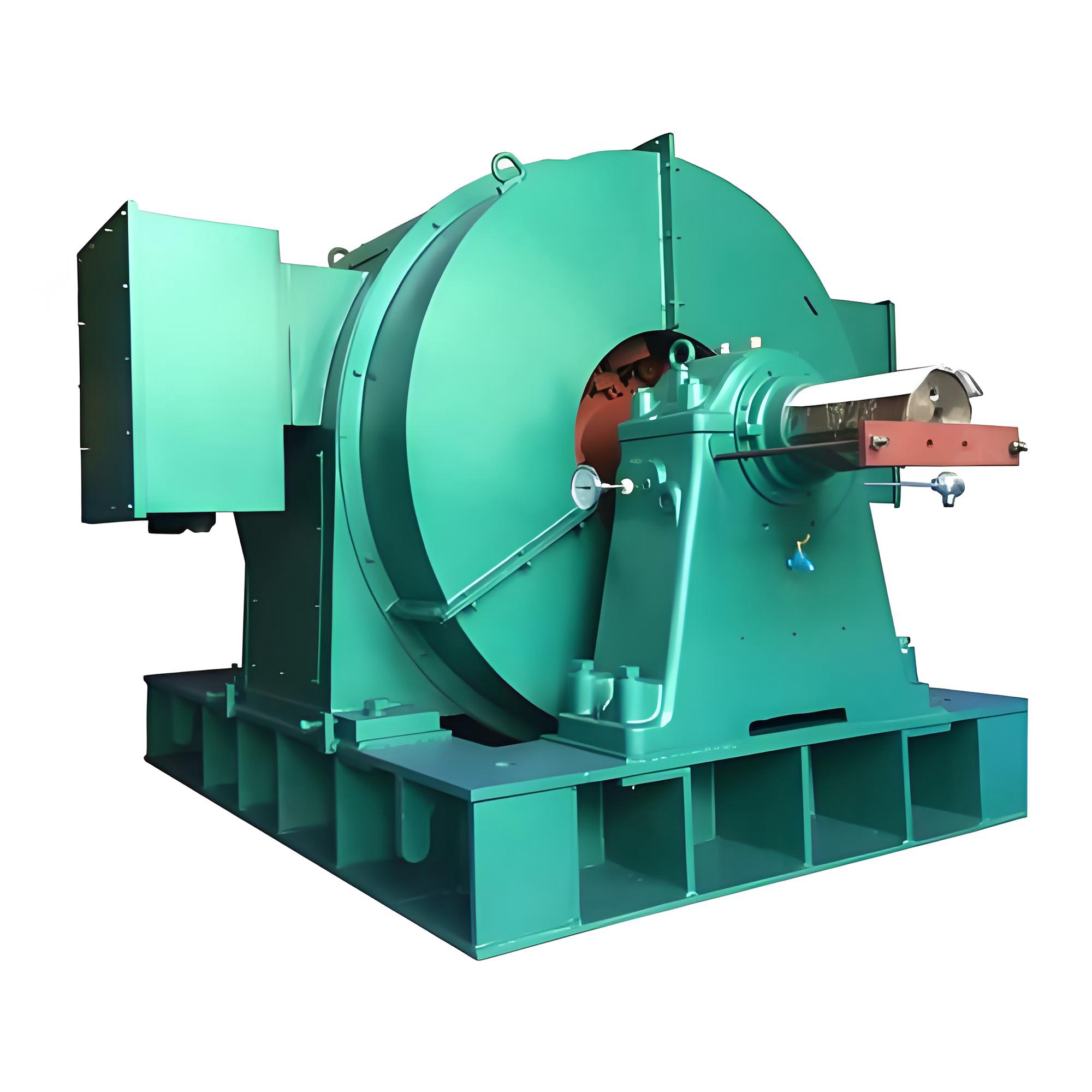

To better visualize the benefits, let's examine a real-world retrofit case. A renowned ceramics manufacturer in Guangdong had long relied on traditional Y-series motors for its ball mills and fan systems on the production line, resulting in low energy efficiency and frequent malfunctions. Following recommendations from energy management experts, the factory replaced 10 of its standard 55kW motors withIE4 Ultra-High-Efficiency Permanent Magnet Synchronous Motor。

The transformed data is encouraging:

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2023/08/1763951132-ye2.png)

- Improved Energy Savings RateThe average power saving rate reached 12.51%.

- Maintenance costs have decreased.Due to the new motor's low temperature rise and minimal vibration, bearing wear has been significantly reduced, extending the maintenance interval from every six months to once every eighteen months.

- Return on InvestmentThe project required a total investment of approximately 300,000 yuan, but the company recouped the entire retrofit cost within 11 months solely through electricity savings.

How to choose the right energy-saving solution?

When selectingEnergy efficient motorsWhen selecting motors, companies should not blindly follow trends but instead match them to actual operating conditions. The primary focus should be on the motor'sLoad factorHigh-efficiency motors achieve the most significant energy savings when operating within the 60% to 100% load range. If an oversized motor is driving a smaller load, consider selecting a lower-power model.

Additionally, integrating variable frequency drive (VFD) technology often yields synergistic benefits where the whole is greater than the sum of its parts. For loads such as fans and pumps, controlling flow by adjusting motor speed via a VFD achieves greater energy savings than traditional valve-based regulation. When combined withEnergy efficient motorsHigh conversion efficiency, capable of maximizing system energy efficiency.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206