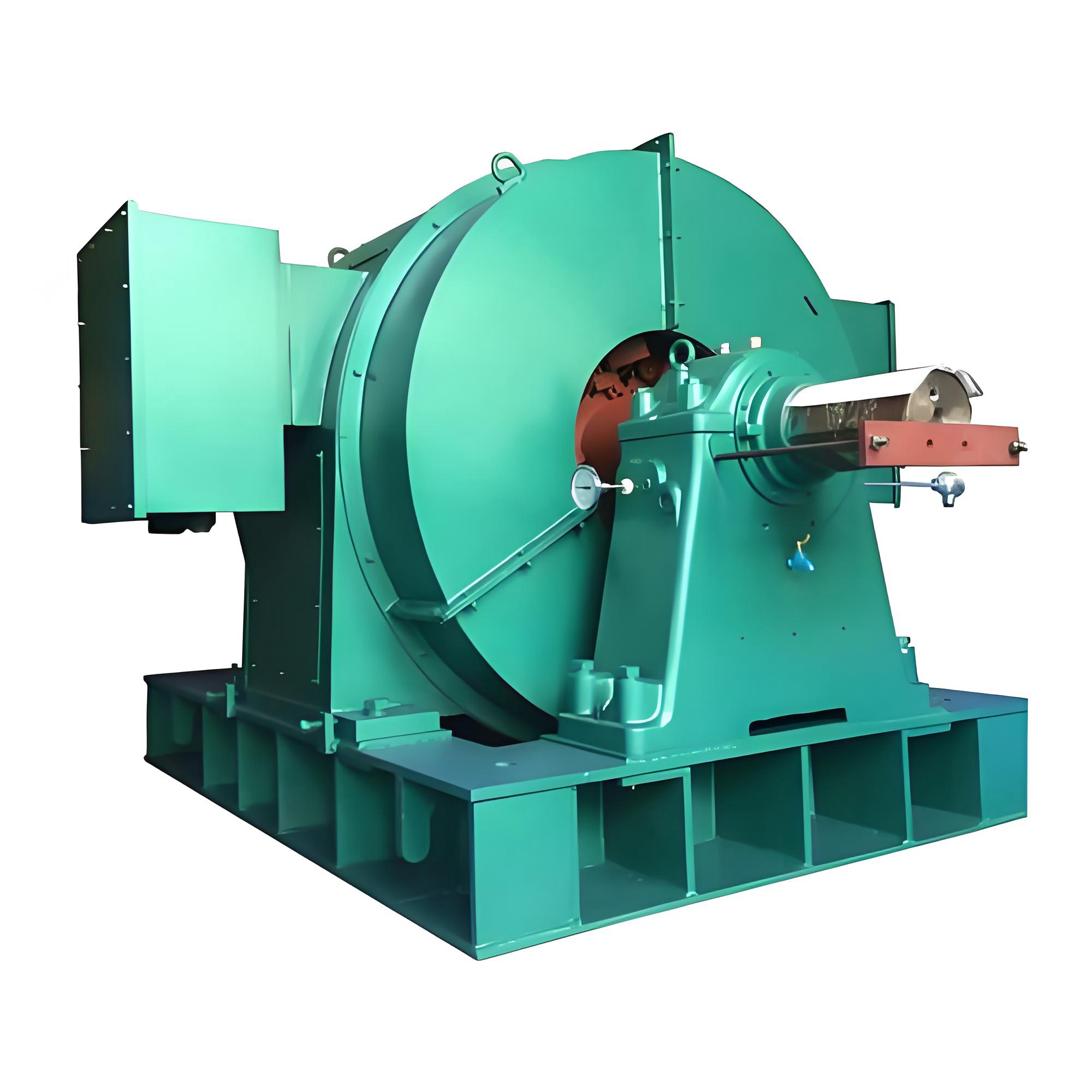

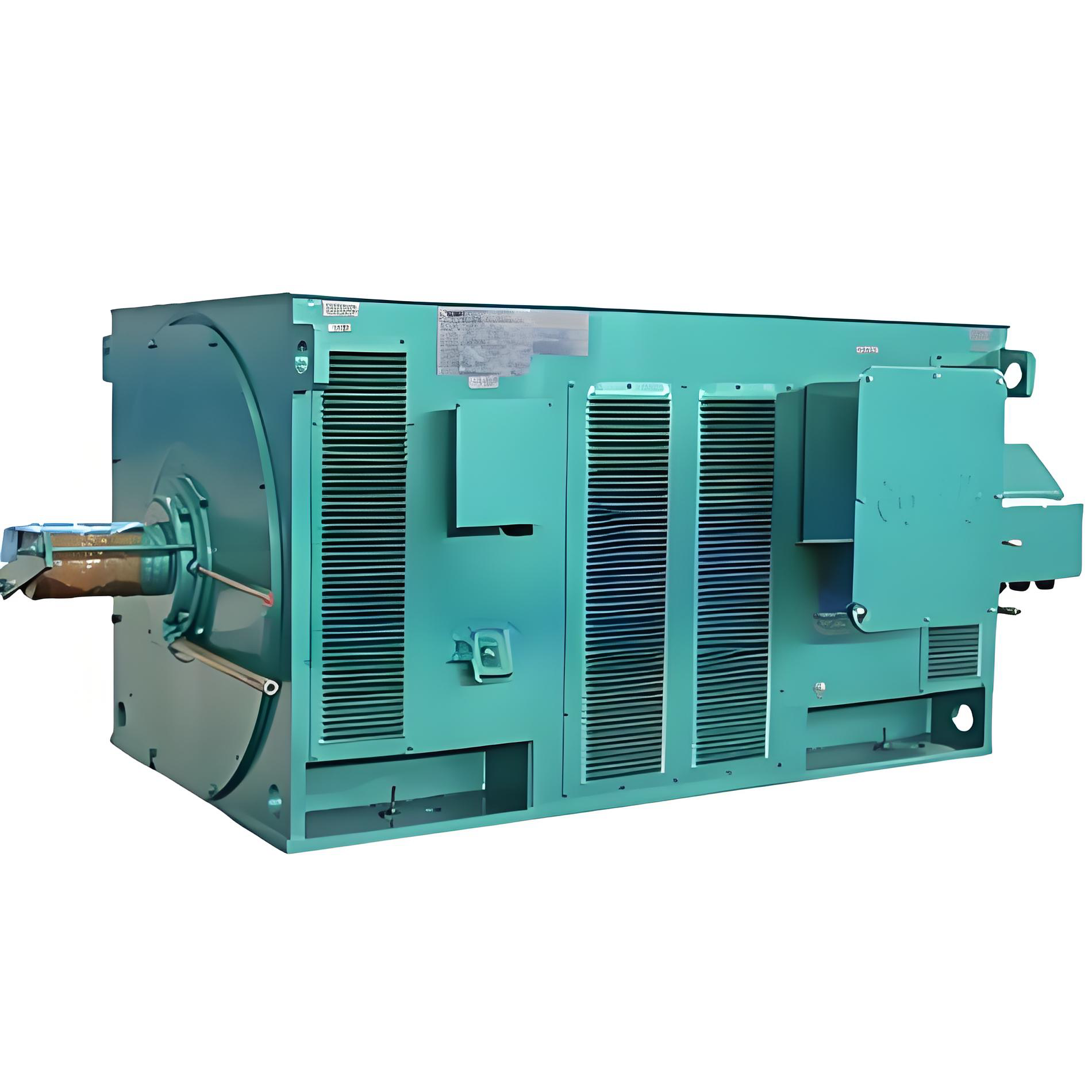

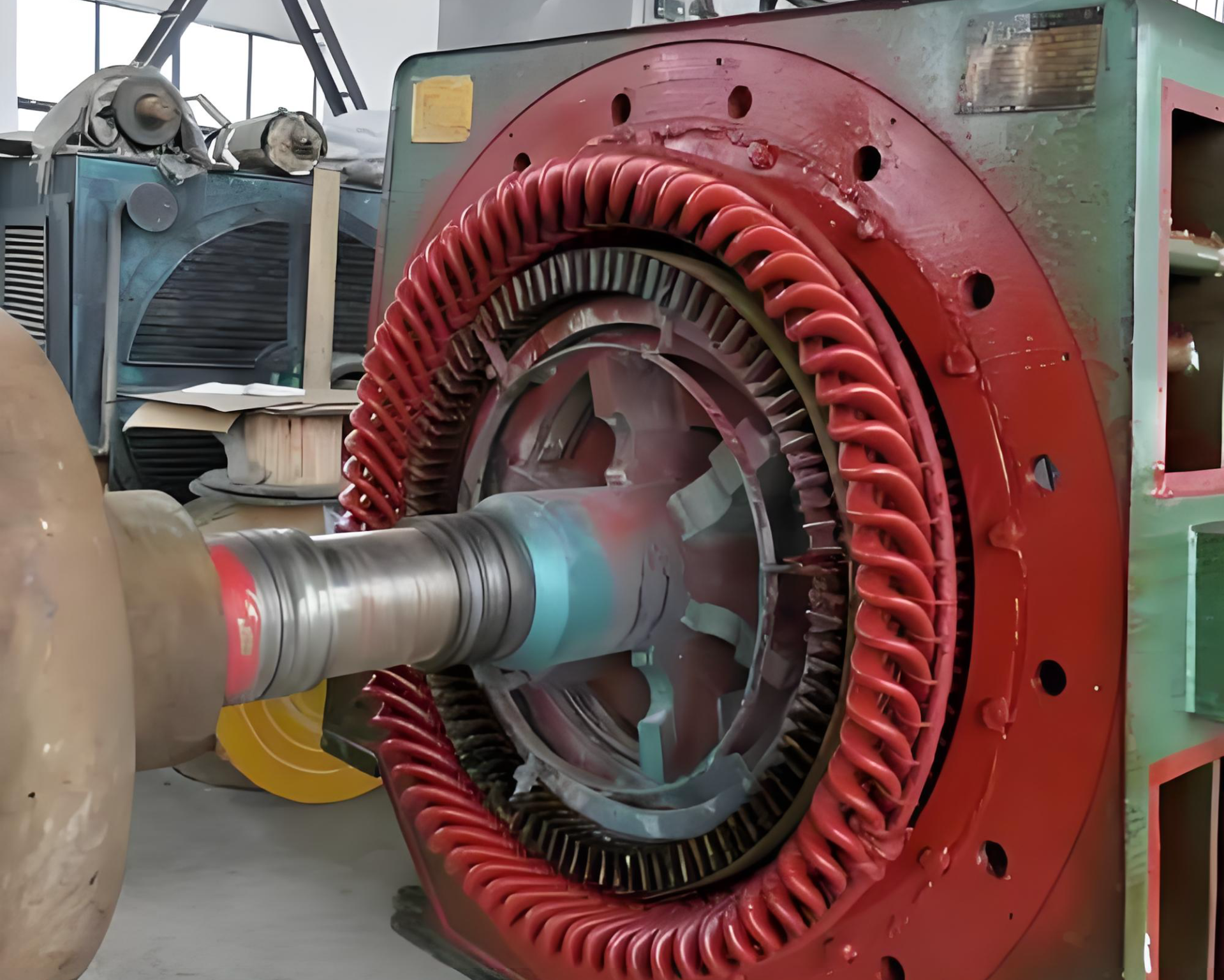

Heavy Duty Starting High Voltage Motors Sigma Motors Strong Power

Heavy-duty starting high-voltage motors, especially the Siemens series, are popular for their power and excellent performance. These motors are typically used in heavy industry, mining, chemicals, etc., and are capable of operating under extreme conditions, providing stable and reliable power support. Key features: High starting torque: Sigma motors are designed with the ability to provide high starting torque.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206