Comprehensive Guide to Selecting High-Efficiency, Energy-Saving Explosion-Proof Motors and Their Application Scenarios

Date: 2025-12-16 Categories: Faq Views: 1887

Excerpt:

Safeguarding the Industrial Heart: Selection Strategies and Safety Maintenance Guidelines for Explosion-Proof Motors In high-risk industries such as petrochemicals, coal mining, and pharmaceuticals, every flammable or explosive particle suspended in the air could become the fuse for disaster. In these hazardous environments riddled with “invisible landmines,” ordinary power equipment is often powerless. Should an electrical spark occur...

Article Catalog[Hidden]

Guarding the Heart of Industry:Explosion-proof motorsSelection Strategy and Security Maintenance Guide

In high-risk industries such as petrochemicals, coal mining, and pharmaceutical manufacturing, every flammable and explosive particle suspended in the air could become the fuse for disaster. In these hazardous environments riddled with “invisible landmines,” conventional power equipment is often powerless. Should an electrical spark occur, the consequences would be unimaginable.Explosion-proof motorsAs the “safety guardian” of specialized industrial equipment, it serves not only as the power source for production lines but also as a steel defense line against explosions. Proper selection and maintenance of this critical equipment directly impacts the safety of a company's personnel and assets.

Core Principle: Not “bombproof,” but “non-detonatable”

Many people areExplosion-proof motorsThere is a misconception that it can remain unscathed in external explosions. In fact, its core design philosophy lies inIsolation and Control。

When electrical sparks occur inside the motor due to closed contacts or winding short circuits, the explosion-proof motor's housing can withstand the pressure generated by an internal explosion. It directs the internal flames or high-temperature gases through specially designedExplosion-proof surfaceCool and extinguish the flame to ensure that by the time it propagates to the exterior of the motor, the energy is insufficient to ignite surrounding explosive gas mixtures.

Scientific Selection: Avoid Overkill and Reckless Risk-Taking“

When selecting explosion-proof motors, power rating alone is insufficient; precise matching to the specific application environment is essential. Incorrect selection not only wastes resources but may also create potential safety hazards.

- Define Hazard Zone Levels:

- In environments where explosive gases frequently occur (such as inside storage tanks), equipment with extremely high protection ratings is typically required. However, in practical motor applications, it is more commonly seen that...Zone 1(Explosive gases may be present during normal operation) andZone 2(Rarely occurring and short-lived). For Zone 1, explosion-proof (Ex d) motors are typically selected; whereas in Zone 2, enhanced safety (Ex e) or non-sparking (Ex n) types may offer better cost-effectiveness.

- Gas Group and Temperature Group:

Different gases have varying ignition temperatures and levels of reactivity. For example, hydrogen belongs to Group IIC and is more hazardous than propane (Group IIA). Therefore, motors suitable for IIA environments must never be used in IIC environments. Additionally, attention must be paid to...Temperature Class (T1-T6)Ensure that the maximum surface temperature of the motor remains below the ignition temperature of the ambient gas.T6-rated (85°C) is the safest and most versatile option.

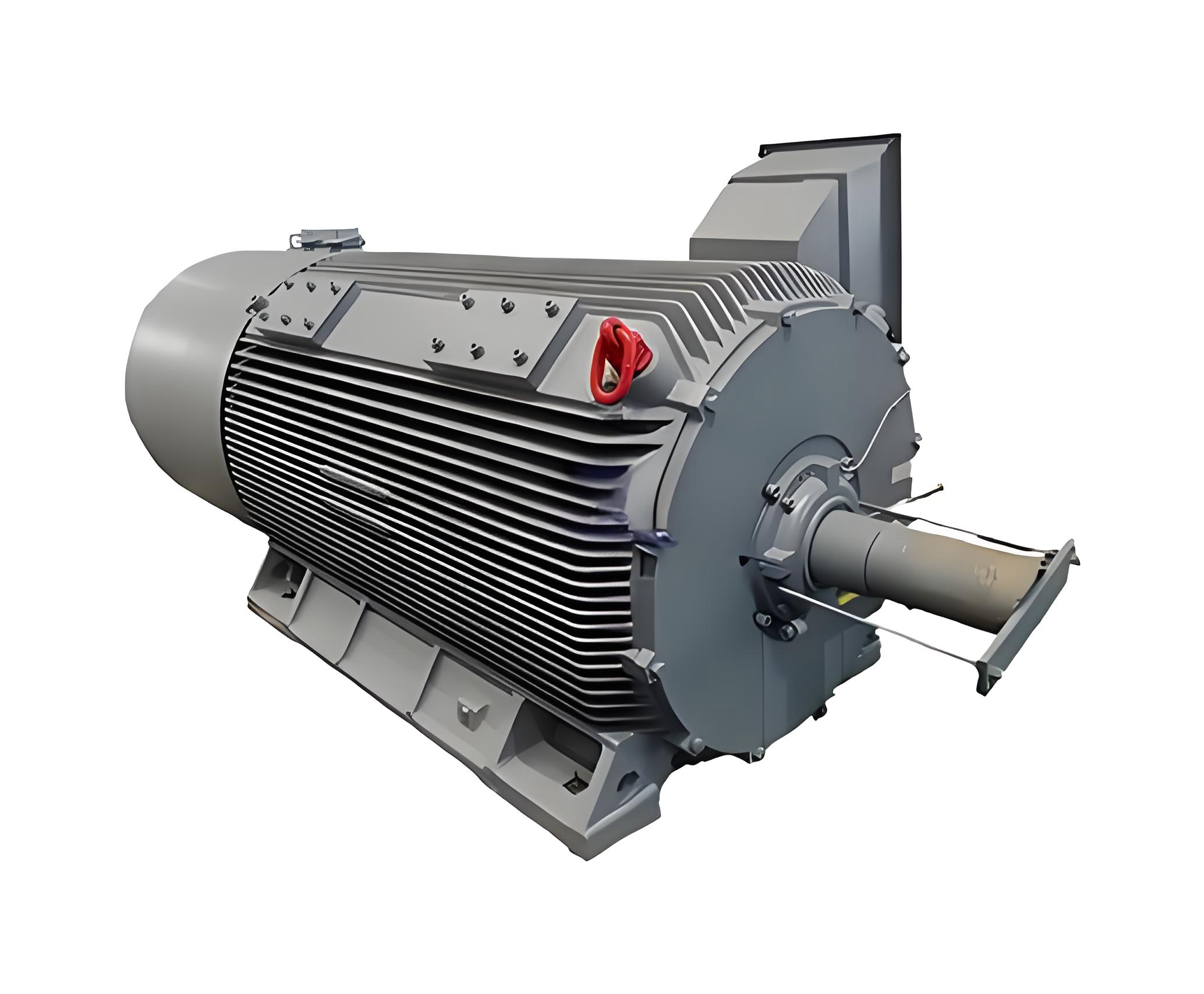

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2025/11/1763988883-24205134.jpg)

Maintenance Practices: Details Make or Break It

Possessing high-qualityExplosion-proof motorsThis does not imply a permanent solution. In actual cases, many accidents stem from non-standardized maintenance practices.

A partial flash explosion once occurred at a chemical plant. The investigation revealed that after maintenance personnel performed servicing on an Ex d explosion-proof motor, they removed the protective cover for aesthetic reasons.The motor housing, along with the explosion-proof joint surface, was coated with a thick layer of paint.This inadvertent error directly compromised the gap precision of the explosion-proof surface, causing internal sparks to escape the housing without effective cooling and ignite the leaked ethylene gas.

Therefore, the following guidelines must be strictly adhered to during routine maintenance:

- Strictly prohibit damaging the explosion-proof surfaces: During disassembly and installation, explosion-proof mating surfaces must be protected against scratches and corrosion. Painting on explosion-proof surfaces is strictly prohibited; only a thin layer of rust-preventive oil may be applied.

- Fasteners must not be replaced arbitrarily: The bolts of explosion-proof motors are typically subjected to special strength treatment. Replacing them with ordinary screws may compromise the housing's pressure resistance.

- Sealing integrity of the introduction device: The sealing ring of the cable entry device (flared end) must match the cable diameter. If it shows signs of aging or loosening, it must be replaced immediately to prevent explosive gases from entering the motor directly through this point.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206