Simo motors successfully solved a large mining company's high-voltage motor bearing system failure

Date: 2023-08-21 Categories: Cases Views: 1073

Excerpt:

Simo's professional and technical team successfully repaired a serious failure of the bearing system of a 1600kW high-voltage motor in the core production line of a large-scale mining company through precision diagnosis and innovative maintenance solutions. Through on-site precision machining technology and professional maintenance program, the team not only quickly restored the equipment operation, but also established a perfect predictive maintenance system for the customer, which effectively avoided the loss of major production stoppages.

Article Catalog[Hidden]

- I. Critical Failure: Sudden Outage of Core Equipment

- II. Precision Diagnosis: Systematic troubleshooting to pinpoint the root cause of the malfunction.

- III. Innovative Maintenance Solutions and Technological Breakthroughs

- IV. Maintenance Effectiveness and Value Creation

- V. Professional Technical Expertise and Service Advantages

- VI. Preventive Maintenance Recommendations

I. Critical Failure: Sudden Outage of Core Equipment

Customer Information:

- Client OrganizationA large mining group's mineral processing plant

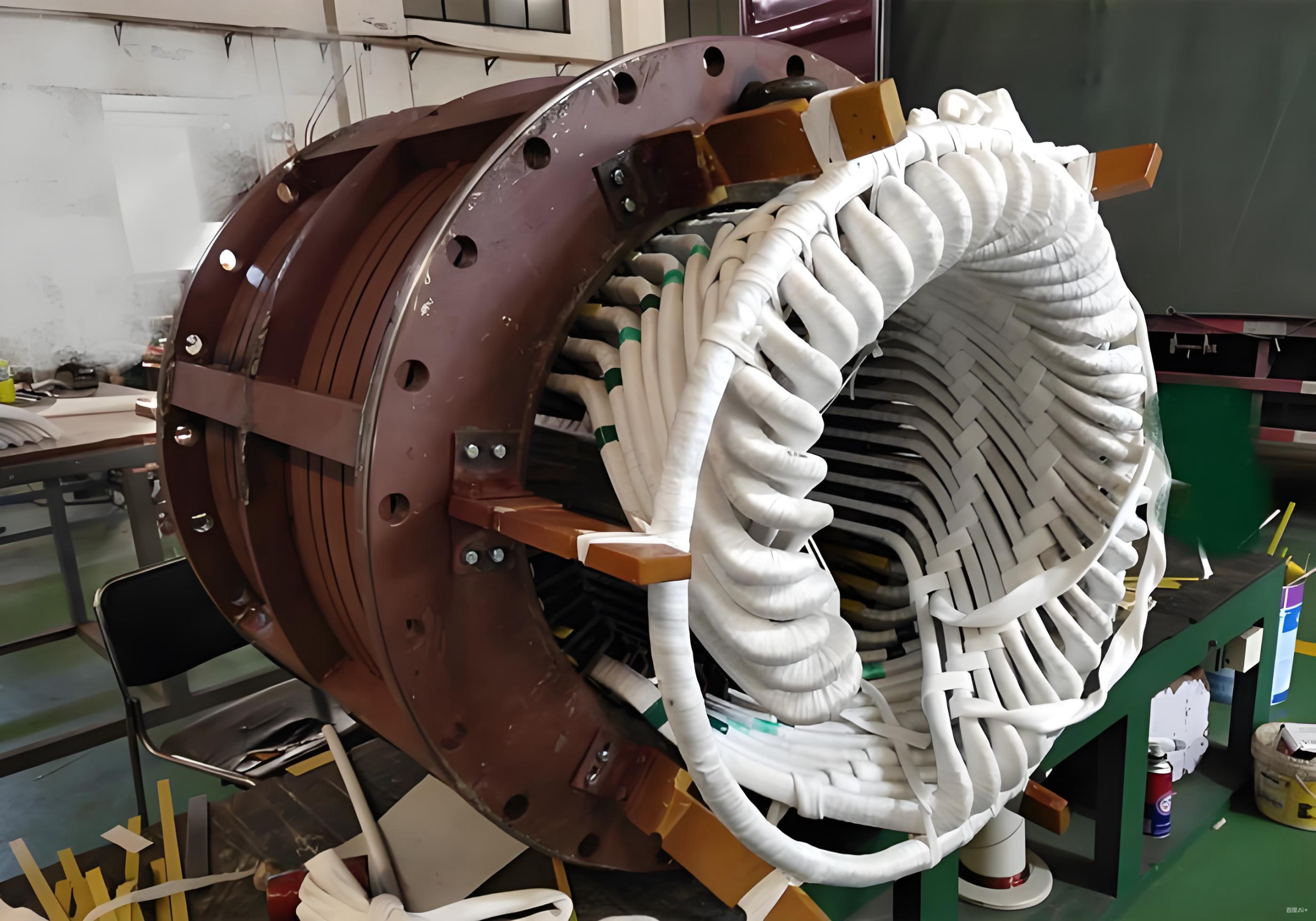

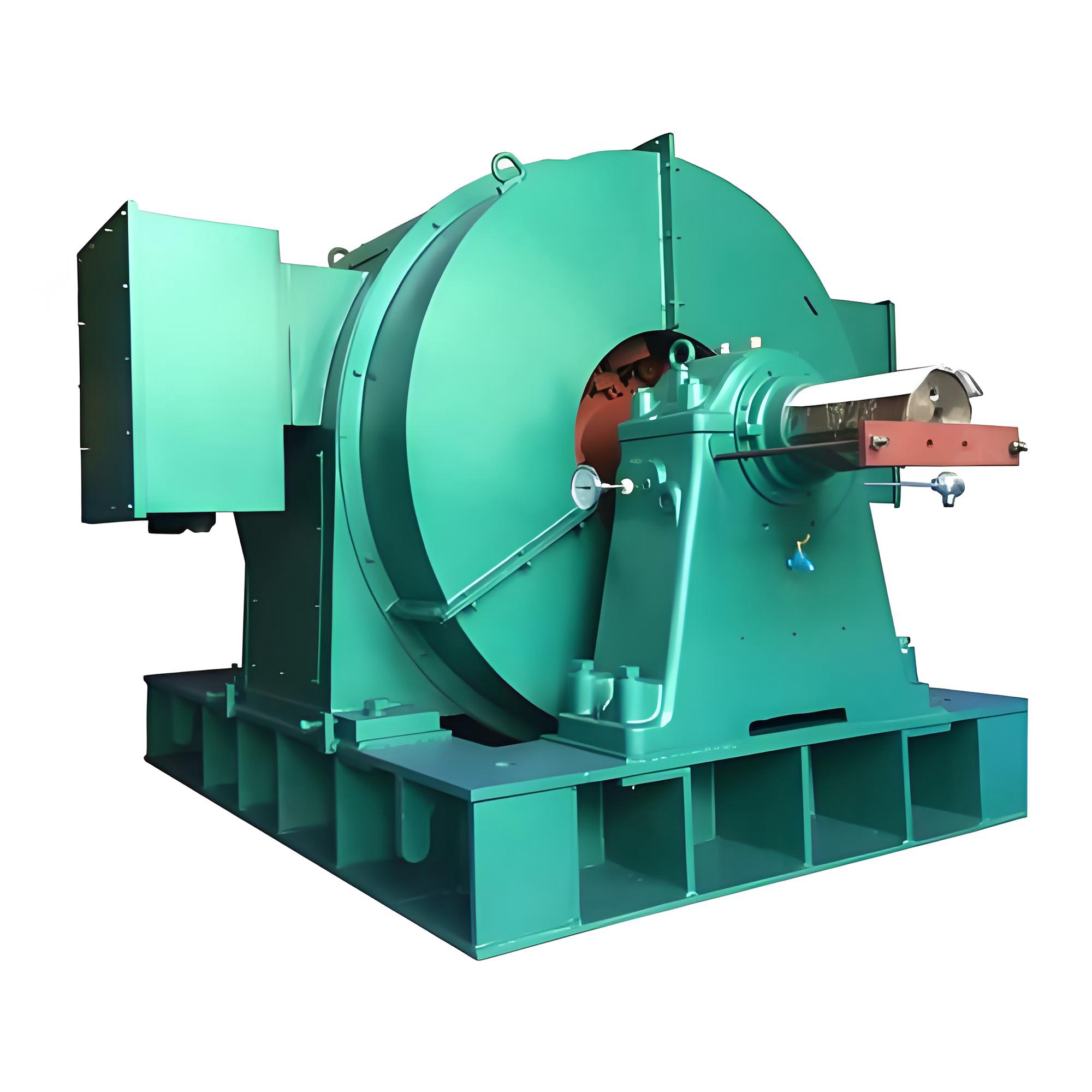

- Equipment TypeYSP Series 10kV High-Voltage Asynchronous Motors

- Key ParametersRated power: 1600 kW Rotational speed: 1490 r/min Weight: 4.8 tons

- application scenarioCore Ball Mill Drive Equipment

- Fault Symptoms:

- During operation, the equipment suddenly experienced severe vibration, causing the drive-end bearing temperature to rapidly rise to 95°C.

- Vibration values reached as high as 9.2 mm/s, far exceeding safe operating standards.

- On-site inspection revealed abnormal noises emanating from the bearing area, necessitating immediate shutdown for repair.

II. Precision Diagnosis: Systematic troubleshooting to pinpoint the root cause of the malfunction.

Simo motorsThe technical team arrived on-site within two hours of receiving the report and immediately initiated a systematic diagnostic process:

1. Multi-dimensional detection and analysis

- Vibration spectrum data is collected using a Swedish-imported vibration analyzer.

- Use an infrared thermal imager to detect temperature distribution patterns.

- Laser alignment inspection was performed, revealing an alignment deviation of 0.18 mm.

- Oil analysis revealed abnormal levels of metal wear particles.

2. Precise Fault Localization

- Vibration AnalysisSpectrum display reveals pronounced characteristic frequencies indicative of outer ring bearing failure.

- Disassembly and inspection confirmationThe bearing housing exhibits severe wear, with dimensions exceeding tolerance by 0.4mm.

- root cause:

- Excessive clearance in the bearing housing causes the bearing to run out of true.

- Minor leakage is present in the lubrication system.

- Equipment misalignment beyond tolerance accelerates bearing damage.

III. Innovative Maintenance Solutions and Technological Breakthroughs

Based on the diagnostic findings, we have developed an on-site repair solution that requires no dismantling:

1. On-site bearing housing repair

- Applications of Nanopolymer Composites:

- Precision processing of wear areas ensures surface cleanliness.

- Dimension restoration using imported polymer composite materials

- Specialized tooling ensures repair precision, with clearance controlled within 0.02mm.

2. System Maintenance and Optimization

- Lubrication System Upgrade:

- Replace high-performance sealing components

- Optimize the grease filling process

- Establish a regular oil testing system

- Improved accuracy:

- Precise calibration using a laser alignment tool

- Accuracy improved to within 0.05mm

IV. Maintenance Effectiveness and Value Creation

1. Verification of Repair Effectiveness

- After repair, the vibration value decreased to 1.6 mm/s, exceeding the equipment's factory standard.

- Bearing temperature has returned to normal and stabilized below 68°C.

- The equipment passed its initial test run successfully and is operating smoothly.

- It has been operating continuously for 11 months and remains in excellent condition.

2. Comprehensive Value Realization

- Time efficiencyOn-site repairs completed in just 48 hours, saving 21 days compared to traditional methods.

- Economic benefitsDirect repair costs amount to just 18% of the equipment replacement cost.

- Production AssuranceAvoided production losses of approximately 8.6 million yuan

- Management EnhancementAssist clients in establishing equipment health management systems

V. Professional Technical Expertise and Service Advantages

1. Core Technical Capabilities

- On-Site Non-Dismantling Repair Technology for Large Motors

- Imported testing equipment and professional analytical capabilities

- Extensive experience in servicing imported equipment

- Comprehensive Quality Assurance System

2. Featured Services

- 24-Hour Emergency Repair Service

- Equipment Health Status Assessment

- Predictive Maintenance Program Development

- Professional Technical Training Support

VI. Preventive Maintenance Recommendations

Based on the experience gained from this case, we recommend:

1. Key Points for Daily Monitoring

- Vibration Value Monitoring: Establish Trend Analysis Records

- Temperature Monitoring: Implement a multi-tiered early warning system

- Regular Oil Testing and Analysis

2. Professional Maintenance Plan

- Perform vibration spectrum analysis monthly

- Conduct laser alignment inspections quarterly.

- Annual Preventive Maintenance

Professional Technical Services

Is your large motor facing similar issues? Would you like to receive the same level of professional repair service?

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206