Diagnosis and Repair: Winding Breakdown Faults in 10kV High Voltage Motors

Date: 2023-08-21 Categories: Cases Views: 975

Article Catalog[Hidden]

I. Fault Background: Sudden shutdown, critical production situation

Device Information:

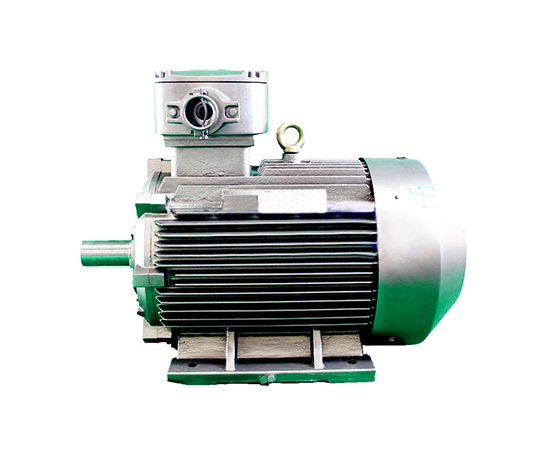

- Equipment Type: Y560-2-12 High-voltage three-phase asynchronous motors

- Key Parameters: Rated power: 355 kW Rated voltage: 10 kV

- Fault Symptom: The motor experienced insulation breakdown during operation.Sudden shutdownand caused the system to trip, severely disrupting continuous production.

Preliminary situation at the scene:

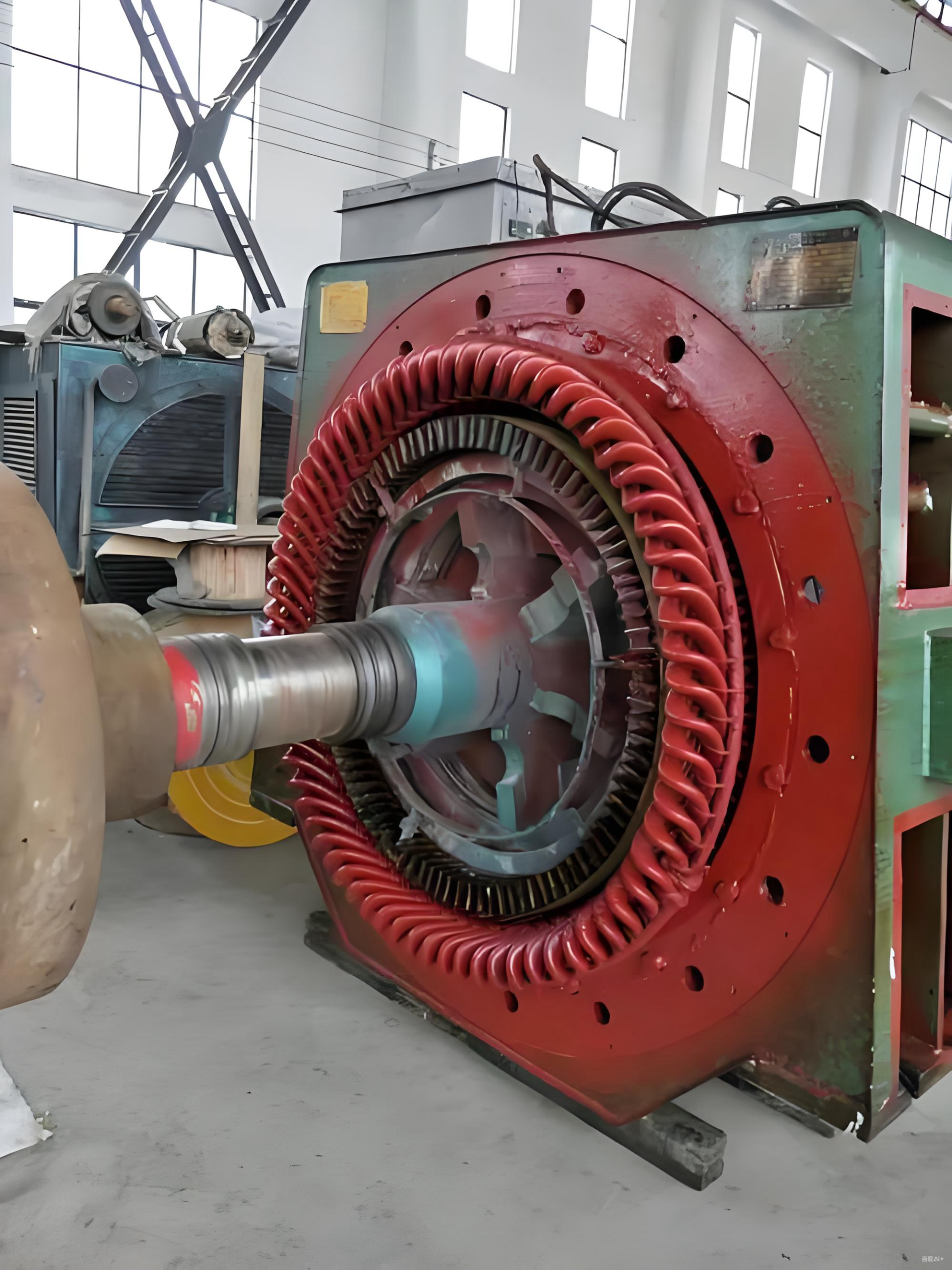

Inspection revealed that the motor stator winding exhibits issues approximately 10 centimeters from the slot opening.Severe burnout failureforming a damaged area approximately 1.8 centimeters in diameter and up to 2 centimeters deep.

II. Unraveling the Threads: In-Depth Diagnosis and Root Cause Analysis

Our team of professional engineers promptly arrived on-site after receiving the service request and initiated a systematic diagnostic process.

1. Initial Maintenance and Failure

The customer performed one repair after the initial failure occurred. The repairer addressed the burn marks.Not properly handledonly passed2 times rated voltage + 1000 V, DC withstand voltage test for 1 minuteThe no-load operating current displayed as 20A, which appeared normal. However, after reloading and operating for 13 days,A secondary breakdown occurred at the exact same location.and the scope of the malfunction has expanded.

2. Root Cause Identification

Through on-site investigation and technical analysis, we have identified the core cause of the recurring failure:

- Deep-seated damage to the iron core: The high temperature of the arc generated by the initial fault not only damaged the winding insulation but also caused the bottom of the burn pit to be scorched.Short circuit between stator silicon steel sheetsForming a short-circuit loop, generating enormousEddy current lossesDuring operation, this localized area remains at high temperatures, ultimately leading to renewed insulation degradation and breakdown.

- Insufficient insulation treatment: The initial repair failed to restore the integrity of the insulation structure at the burn point, leaving a critical safety hazard. The non-standard insulation repair process could not withstand long-term electrical and thermal stresses, directly causing the recurrence of the failure.

The root cause of such failures lies in the initial repair failing to identify and address deep core damage resulting from insulation breakdown.。

III. Tailored Solutions: Professional Repair Services

To address the root causes outlined above, we have developed and implemented a comprehensive overhaul plan that goes far beyond conventional measures.

1. Detailed disassembly and cleaning

- Disassemble the motor using specialized tools and carefully remove the rotor.

- Thoroughly clean the stator windings, carefully removing all carbonized insulation material to ensure no contaminants remain.

2. Core Damage Repair

- Clear the short circuit points: Perform on the silicon steel sheets fused by arc short-circuiting within the burn pitFine grinding and separationRestore inter-plate insulation and eliminate eddy current loops. This is a critical step to ensure the issue does not recur after repairs.

- Filled with special materials: utilizationHigh-Performance Epoxy Filler CompoundFill and repair the repaired potholes. This material possessesExcellent electrical insulation properties, high thermal conductivity, and robust mechanical strengtheffectively isolates impurities, prevents moisture, and improves heat dissipation.

3. Stator winding re-insulation

- Implement windingWhole-Part Vacuum Pressure Impregnation (VPI) TreatmentEnsure the insulating varnish fully penetrates to form a complete, gap-free insulating structure.

- Strictly implement the impregnation process to ensure the new insulation system possesses high dielectric strength and extended service life.

4. Full Assembly and Testing

After completing the repairs, we conducted multi-level testing and verification:

- Insulation resistance test: Measure the insulation resistance between windings and ground, as well as between phases, to ensure compliance with specifications (for repaired windings).High voltage motors, typically requiresInsulation resistance shall not be less than 5 MΩ.)。

- DC Withstand Voltage and Leakage Current Testing: Reapply the DC high voltage and monitor the leakage current to verify the uniformity and reliability of the insulation treatment.

- No-Load and Short-Circuit Tests: Measurements of no-load current and losses both showed normal results, indicating that the motor's magnetic circuit and electrical circuit have been successfully restored.

IV. Maintenance results and customer value

- The fault is completely eradicated: After repair, the motor has been operating continuously and stably for over12 monthsNo further insulation or overheating faults have occurred.

- Restore efficient production: The customer's critical production line was restored, preventing significant economic losses that would have resulted from prolonged equipment downtime.

- Earn long-term trust: This successful repair service earned high praise from the customer, who subsequently signed a maintenance agreement covering all high-voltage motors.

V. Case Summary and Prevention Recommendations

1. Core message

- Accurate diagnosis is the prerequisite: High-voltage motor maintenance must never be a case of treating symptoms rather than the root cause. It is essential to conduct an in-depth analysis of the underlying failure, particularly...Investigate potential core damage caused by insulation issuesand other deep-seated risks.

- Standardized maintenance is the guarantee: Every step of the repair process—from cleaning and restoration to impregnation—must adhere to the highest standards of technical specifications. Attention to detail determines success or failure; any oversight may sow the seeds of future failure.

2. Preventive Maintenance Recommendations for High-Voltage Motors

To prevent potential issues, we recommend that all users:

- Establish a regular inspection system: Regularly measure and record the motor'sWinding Insulation Resistancevibration, bearing temperature, and other key parameters.

- Utilizing advanced predictive maintenance technology: IntroductionOnline Partial Discharge Detection、Infrared Thermal ImagerAdvanced methods such as periodic scanning can detect internal insulation defects and localized hot spots in advance.

- Strictly enforce lubrication management: Select the appropriate grease according to the manufacturer's specifications and replace or replenish it regularly to prevent motor operating temperatures from rising excessively due to lubrication issues.or bearing damage.

- Focus on ventilation and cooling systems: Regularly clean the motor ventilation ducts and coolers to ensure proper heat dissipation and prevent overheating.Excessive temperature riseAccelerate insulation aging.

Call to Action (CTA):

Is your high-voltage motor also facing the recurring problem of “repeated repairs and repeated failures”? Are you seeking reliable protection for your critical equipment?

Contact us immediatelySimo motorsExpert TeamGet a free technical consultation and initial equipment health assessment! We are committed to providing the same professional and rigorous high voltage motor repair, maintenance and full life cycle management services as in this case.

Xi'an Simo Motor -- Your expert for high-voltage motor system solutions

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206