A large mining group crushing workshop

Date: 2023-08-21 Categories: Cases Views: 1007

Article Catalog[Hidden]

I. Customer Background and Fault Symptoms

Client: A large mining group crushing workshop

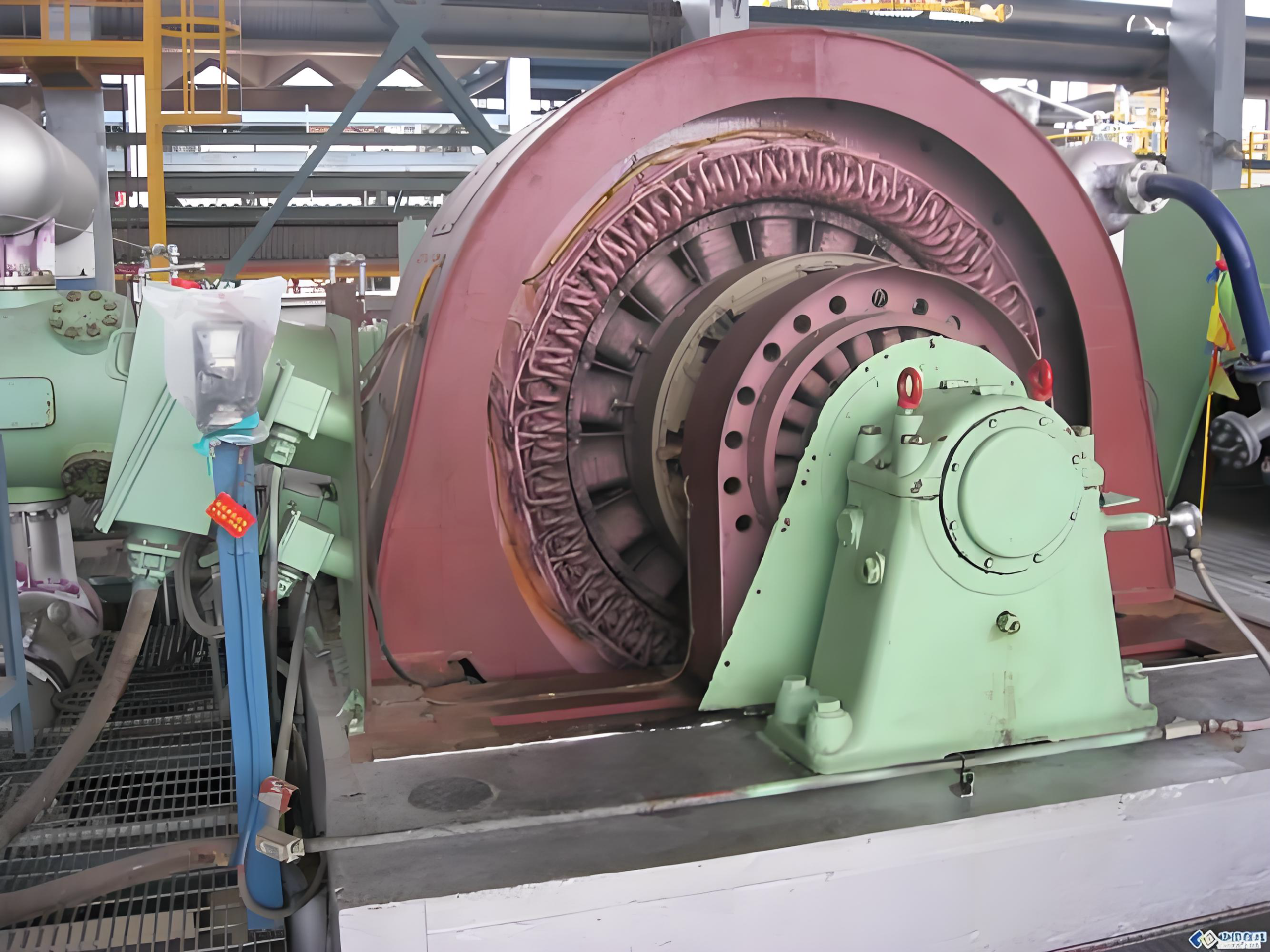

Equipment: 10kV, 1250kW synchronous motor, driving the core crusher

Fault Symptom:

- Violent vibration: During operation, the vibration value at the drive-end bearing location of the motor increased sharply, far exceeding the permissible range specified in ISO 10816.

- Synchronization loss: Occasional misstep alarms have caused production line tripping and shutdowns, severely impacting production schedules.

- Abnormal noise: The bearing area is accompanied by a regular rumbling noise.

Faced with an unexpected malfunction, the production line was at risk of a complete shutdown, with every hour of downtime representing significant financial losses. After the customer's technical team conducted an initial troubleshooting effort without success, they urgently contacted our company to request technical support.

II. Precise Diagnosis: Our Diagnostic Process

Our team of senior engineers promptly arrived on-site with specialized diagnostic equipment and conducted a systematic diagnostic assessment:

- Preliminary Inspection and Data Collection:

- utilizationVibration AnalyzerPerform multi-point, multi-directional vibration spectrum acquisition on the motor bearing housing and base.

- Inspecting the motor alignment revealed that the alignment accuracy falls within acceptable limits, thereby ruling out misalignment as a potential cause.

- Measurements of the DC resistance, insulation resistance, and absorption ratio of the motor's three-phase windings indicate that the electrical performance parameters are essentially normal.

- Deep Spectrum Analysis—Uncovering the Culprit:

Through in-depth analysis of the vibration spectrum, we uncovered a crucial clue:- Characteristic frequency: Significant changes have appeared in the spectrum.Characteristic Frequency of Bearing Outer Ring Failureand its higher harmonics.

- Rotational Speed Frequency Sideband: On either side of the characteristic frequency, precise frequency shifts (1X) sidebands are present, which are typical indicators of bearing wear.

- Conclusion: The drive-end bearing exhibits severe wear and fatigue spalling.This is the direct cause of severe vibration and abnormal noise.

- Root Cause Analysis:

Bearing damage is often a result rather than a cause. Upon further disassembly and inspection, we found that:- Improper bearing clearance: The bearing clearance selected during the original installation may not be suitable for the current actual operating load conditions.

- Poor lubrication: The grease in the bearing cavity has aged and discolored, and the insufficient grease filling has caused the bearing operating temperature to rise, accelerating wear.

- Indirect impact: Prolonged abnormal vibration has caused the motorRotor Dynamic Balancingwas damaged and slightly affected the motor and load.Air Gap UniformityThis is the underlying cause of occasional loss of step.

III. Tailored Solutions: Customized Maintenance Solutions

Based on the diagnostic results, we developed and implemented a comprehensive repair plan for the customer:

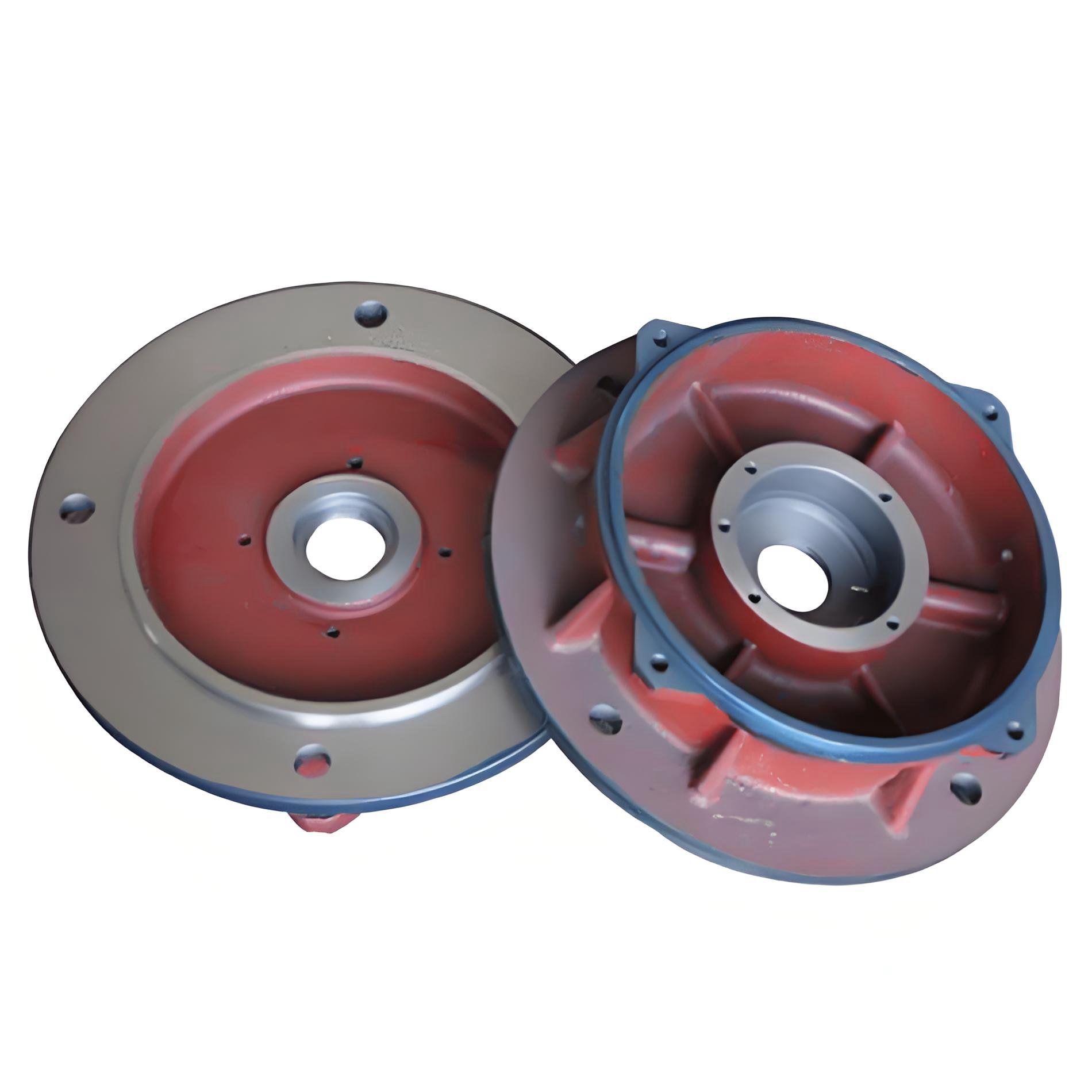

- Core Component Replacement and Repair:

- Precision Bearing Replacement: High-precision SKF bearings of the manufacturer's specified model are selected and installed strictly according to the hot-mounting process to ensure optimal clearance and fit tolerances.

- On-site Dynamic Balancing of Rotors: Perform precision balancing on the rotor using a dynamic balancing machine to reduce residual imbalance to below G2.5 grade, thereby eliminating vibration sources at their root.

- Comprehensive Cleaning and Inspection: Blow out and clean the stator and rotor, inspect the core and windings to ensure no damage is present.

- Professional assembly and debugging:

- Standardized Lubrication Management: Use high-performance grease specified for the customer's operating conditions, and precisely control the lubricant quantity and application process.

- Laser Alignment Calibration: Using a laser alignment tool, the motor and crusher were realigned with an accuracy within 0.05mm.

- Air Gap Measurement and Adjustment: Ensure uniform air gap between the stator and rotor to maintain magnetic field symmetry and prevent loss of synchronization.

- Preventive Maintenance Recommendations:

After completing the repairs, we provided the customer with long-term preventive maintenance recommendations:- Establish a regular vibration monitoring mechanism, collecting vibration data once a month.

- Establish a strict lubrication schedule and document each lubrication instance.

- Regularly inspect the tightness of foundation bolts and the cooling system.

IV. Maintenance results and customer value

- Vibration values have decreased significantly: After repairs, vibration values at all motor measurement points decreased to below 2.0 mm/s, exceeding the equipment's factory specifications.

- Operating smoothly with no abnormalities: The abnormal noise has completely disappeared, and the motor temperature rise is normal.

- Production resumes efficiently: Since the repair, the motor has operated continuously and stably for over six months without any further instances of loss of synchronization or abnormal shutdowns.

- Creating value for customers: This precise and efficient repair not only prevented millions of yuan in production losses for the customer due to prolonged downtime of core equipment, but also helped establish a comprehensive equipment health management system through professional preventive recommendations. This transition shifts the approach from reactive maintenance to proactive prevention.

V. Case summary and inspiration

High-voltage synchronous motors serve as the “heart” of industrial production, with their operational health directly impacting the stability of the entire system. The success of this maintenance case hinged on:

- Scientific diagnosis is the prerequisite: Relying on advanced instruments and professional spectrum analysis techniques is essential for pinpointing the root cause of faults, thereby avoiding a piecemeal approach to troubleshooting.

- Standardized maintenance is the guarantee: From component selection to assembly processes, every step must strictly adhere to standards—details determine success or failure.

- Prevention is paramount: Establishing a comprehensive predictive maintenance system can nip failures in the bud, serving as the cornerstone for achieving long-term, trouble-free equipment operation.

Call to Action (CTA):

Is your factory also facingHigh voltage motorsAre you struggling with “intractable problems”? Do you want to build a robust “firewall” for your core equipment?

Contact us immediatelyGet free technical consultation and a preliminary equipment health assessment! Our expert team stands ready to provide you with high-voltage motor repair, maintenance, and intelligent monitoring services that match the same level of professionalism and efficiency as those in the case study.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206